Audi 2011 Annual Report Download - page 85

Download and view the complete annual report

Please find page 85 of the 2011 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200 -

201

201 -

202

202 -

203

203 -

204

204 -

205

205 -

206

206 -

207

207 -

208

208 -

209

209 -

210

210 -

211

211 -

212

212 -

213

213 -

214

214 -

215

215 -

216

216 -

217

217 -

218

218 -

219

219 -

220

220 -

221

221 -

222

222 -

223

223 -

224

224 -

225

225 -

226

226 -

227

227 -

228

228 -

229

229 -

230

230 -

231

231 -

232

232 -

233

233 -

234

234 -

235

235 -

236

236 -

237

237 -

238

238 -

239

239 -

240

240 -

241

241 -

242

242 -

243

243 -

244

244 -

245

245 -

246

246 -

247

247 -

248

248 -

249

249 -

250

250 -

251

251 -

252

252 -

253

253 -

254

254 -

255

255 -

256

256 -

257

257 -

258

258 -

259

259 -

260

260 -

261

261 -

262

262 -

263

263 -

264

264 -

265

265 -

266

266 -

267

267 -

268

268 -

269

269 -

270

270 -

271

271

|

|

Fuel consumption and emission fi gures at the end of the Annual Report

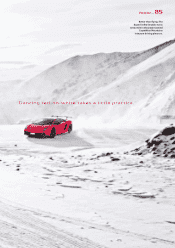

In a bright hall on the grounds of the Ingolstadt

plant, the new Audi RS 4 rests on a stand of solid

steel, accessible from all sides. The Ibis White

paint of the RS 4 is covered with colorful numbers,

lines and stickers: Gap, concept, 0.3, 0.2 and 0.1 are

written on the engine hood. Every detail of the vehicle is

checked here on the master jig. Measurements are taken

to make sure, for example, that the Singleframe is fl ush

with the engine hood and the gaps are even. Deviations are

precisely measured to a tenth of a millimeter.

The measurements on the master jig are just one of

the checks that an Audi has to undergo. Each has a long

quality history. From the fi rst design sketch to the fi nished

product and beyond, all specialist areas place great

emphasis on quality. Vehicle reliability and durability are

just as important here as precision and visual appeal.

The understanding of quality goes far beyond the relia-

bility so appreciated by the customer. “Quality encom-

passes everything that a customer can experience in our

cars. Quality is what you can see, hear, sense and feel,”

says Werner Zimmermann, Head of Audi Quality Assurance.

“The incomparable Audi experience – high reliability

together with comfort and sportiness, precision and

sophistication – would not be possible without it.”

This holistic approach to quality begins with the choice

of materials. From the leather for the seats to the

carbon used in the body and the mix of materials in the

engine block: Everything is carefully examined. Every

piece of leather used in an Audi vehicle – on the steering

wheel, in the cabin or on the seats – undergoes 45 tests

alone to test its durability. The fi rst stage is completed

when all components satisfy the brand’s stringent quality

requirements.

An Audi comprises some 12,000 parts. With the

numerous equipment versions of the individual models,

there are millions of possible ways to put them together.

Work in the master jig therefore begins long before the

start of production. The aim is to fi ne-tune the fi t, the

visual appeal and the haptics for both the interior and

exterior – and this applies to each and every model.

Individual parts are grouped into assemblies or complete

vehicles and assessed. “Despite modern digital modeling

methods, this tangible master jig is indispensable for us,”

says Zimmermann.

That’s because the master jig enables not just the fi ne-

tuning of strictly objective criteria, but also the subjective

consideration of the whole. The gaps around the fuel tank

cap of the RS 4, for example, are intentionally diff erent

Audi vehicles are measured, described and evaluated both inside and out on the master jig. Any deviations are recorded on the car.

The objective is to coordinate all components, gaps and fl ush alignments precisely with one another.

PHOTOS | BERNHARD HUBER/AUDI AG (2); MYRZIK UND JARISCH/AUDI AG (3)

From the sketch to the fi nished car, Audi always places great emphasis on quality.