Audi 2011 Annual Report Download - page 172

Download and view the complete annual report

Please find page 172 of the 2011 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200 -

201

201 -

202

202 -

203

203 -

204

204 -

205

205 -

206

206 -

207

207 -

208

208 -

209

209 -

210

210 -

211

211 -

212

212 -

213

213 -

214

214 -

215

215 -

216

216 -

217

217 -

218

218 -

219

219 -

220

220 -

221

221 -

222

222 -

223

223 -

224

224 -

225

225 -

226

226 -

227

227 -

228

228 -

229

229 -

230

230 -

231

231 -

232

232 -

233

233 -

234

234 -

235

235 -

236

236 -

237

237 -

238

238 -

239

239 -

240

240 -

241

241 -

242

242 -

243

243 -

244

244 -

245

245 -

246

246 -

247

247 -

248

248 -

249

249 -

250

250 -

251

251 -

252

252 -

253

253 -

254

254 -

255

255 -

256

256 -

257

257 -

258

258 -

259

259 -

260

260 -

261

261 -

262

262 -

263

263 -

264

264 -

265

265 -

266

266 -

267

267 -

268

268 -

269

269 -

270

270 -

271

271

|

|

169

Management Report

134 Audi Group

143 Business and underlying

situation

159 Financial performance

indicators

162 Social and ecological aspects

162 Employees

166 Audi in society

167 Location-based

environmental aspects

170 Product-based

environmental aspects

175 Risks, opportunities

and outlook

187 Disclaimer

benches at Neckarsulm are running, they generate power that can be used at the plant by being

connected to generators. Then there is an extra-light body manufacturing tool made largely

from carbon fiber-reinforced polymer (CFRP) and developed by the Audi Toolmaking Shop. Using

this tool cuts power consumption by around 43 percent compared with a conventional version.

Innovative joining techniques in body manufacturing – such as spot welding, laser welding and

bonding techniques – also help to cut consumption of operating materials and energy. A modern

combined heat, power and refrigeration plant at Ingolstadt as well as heat recovery systems and

the use of district heating have furthermore long proved very successful for the Audi Group.

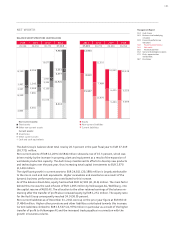

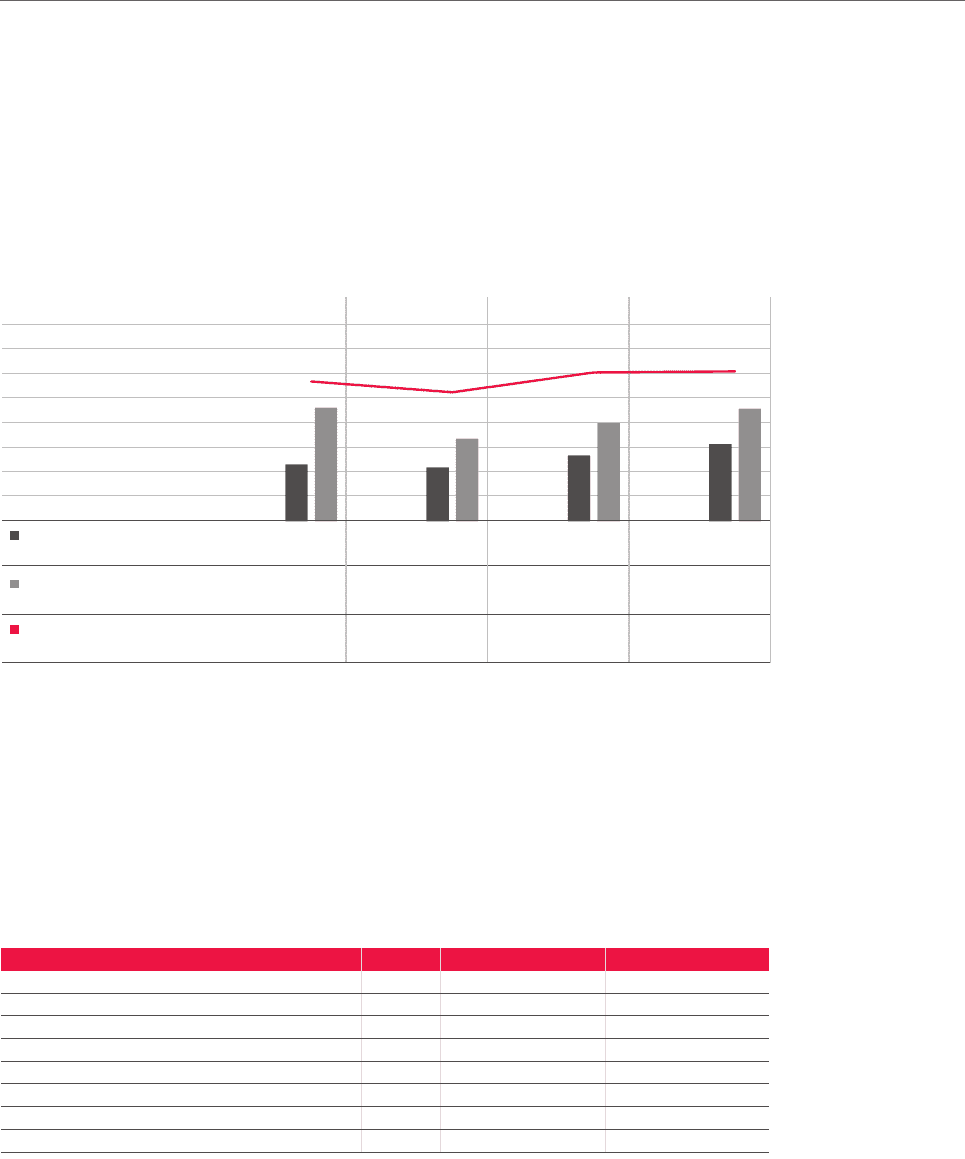

DEVELOPMENT IN OVERALL ENERGY CONSUMPTION, VEHICLE AND ENGINE PRODUCTION BY THE AUDI GROUP 1)

Vehicle production

(thousand units)

Engine production

(thousand units)

1,102

1,648

2,491

Total energy consumption

(in GWh)

800

400

0

2011201020092008

2,400

2,000

1,600

1,200

2,800

1,292

1,884

2,509

953

1,902

2,337

902

1,384

2,157

2)

1) Ingolstadt, Neckarsulm, Brussels (excluding Volkswagen Polo), Győr and Sant’Agata Bolognese plants; incl. CKD production

2) 2011 figures provisional

The Audi Group’s overall energy consumption has been kept virtually stable in recent years.

Energy consumption in the past fiscal year showed only a slight year-on-year rise despite the

increased production volume. A large number of efficiency measures meant that it increased

at a lower rate than the production volume.

The other key environmental figures that the Audi Group observes in addition to energy con-

sumption also reflect the increased production volume.

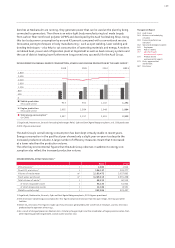

ENVIRONMENTAL STRUCTURAL DATA 1)

2011 2010

VOC emissions 2) t 2,380 1,913

Direct CO2 emissions 3) t 196,137 203,277

Volume of waste water m³ 2,180,472 2,057,863

Fresh water purchased m³ 3,229,515 2,991,498

Total volume of waste 4) t 68,312 60,513

of which recyclable waste t56,130 51,922

of which disposable waste t12,182 8,591

Metallic waste (scrap) t335,286 323,497

1) Ingolstadt, Neckarsulm, Brussels, Győr and Sant’Agata Bolognese plants; 2011 figures provisional

2) VOC emissions (volatile organic compounds): This figure comprises emissions from the paint shops, test rigs and other

facilities.

3) Direct CO₂ emissions: This figure is made up of CO₂ emissions generated by the use of fuel at the plant, and CO₂ emissions

produced by the operation of test rigs.

4) As a result of changed processes (Neckarsulm), statutory changes (Győr) and the remediation of legacy contamination from

other reporting periods (Ingolstadt), overall waste volumes rose.