Audi 2011 Annual Report Download - page 56

Download and view the complete annual report

Please find page 56 of the 2011 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Innovation _

53

Technical Development in

Ingolstadt is hard at work on the

next generations of vehicles. The

VSC, for example, supports the entire

development process of a new model,

from design to construction of the

prototype and the pre-series phase

to the start of series production.

This

support applies not just to the product

itself, but also to the materials and

technologies used as well as the work

processes that are required later for

series production of the vehicles.

“The shortened communications

paths enable the optimal networking

of all departments involved in vehicle

construction,” explains Josef Habla.

Roughly 850 employees work in the

high-tech Ingolstadt facility, which

was opened in 2008. They are all

highly motivated, because they have

the opportunity to be involved in all

the latest developments and to take a

peek into the future.

The VSC helps the Audi engineers

to break new ground in many cases.

Even complex development processes

can be managed more eff ectively. For

instance, the experience gleaned from

the A1 e-tron fl eet trial launched

in 2011 can fl ow directly into

further development. “Such parallel

developments would no longer

even be possible with a classic test

workshop,” says Heinz Hollerweger.

It is becoming increasingly

important to fi ne-tune the individual

vehicle components to one another at

the start of the development process.

That’s because the technologies will be

more intermeshed in the future than

is the case today. Electrifi cation of

the drivetrain, for example, presents

new challenges for the body structure

that must be considered in the

design and the selection of materials.

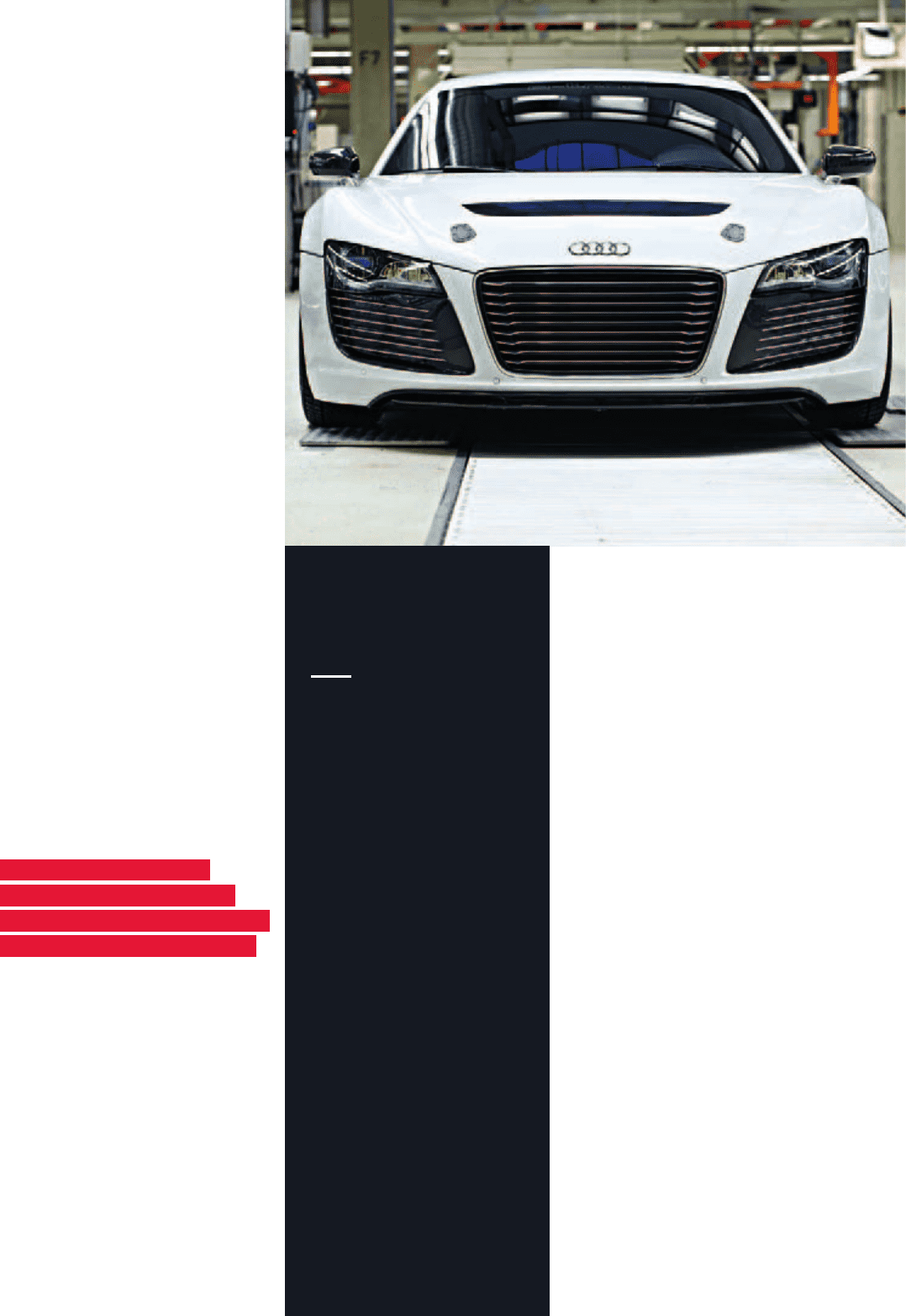

The Audi brand has long had a core

competence in this regard that plays a

decisive role for the car of the future:

lightweight construction. Since 1994,

the Company has produced around

700,000 vehicles with the Audi Space

Frame (ASF) – both all-aluminum and

hybrid aluminum structures – and

demonstrated its expertise in large-

scale lightweight construction in the

process. In the current model lineup,

the A8 luxury sedan and the R8 high-

performance sports car represent

the ASF principle in its purest form.

The body of the TT compact sports

car is a hybrid aluminum and steel

construction, and the bodies of the

A7 Sportback and the new A6 include

a large proportion of aluminum in

addition to steel. The Audi engineers

are convinced that the new Audi Space

Frame of multimaterial construction,

in which components of aluminum,

steel and carbon fi ber-reinforced

polymers are joined together, is

the right approach for the future of

volume vehicle production. At Audi,

lightweight construction does not

mean concentrating on one material,

but rather working intelligently and

fl exibly with a variety of materials.

“The aim is to use the smallest amount

of material possible in the ideal place

to achieve the best performance,”

explains Peter Fromm, “in a way that

is suitable for volume production.”

Audi pools the know-how required

to do this under the term “ultra.” The

intent is to make the vehicles more

agile while reducing fuel consumption

and, in the case of electric mobility,

off setting the weight disadvantage

Around 1,800 people worldwide

work in the Audi Group’s

pre-series center workshops

and offi ces, including some 850

employees in Ingolstadt. The

32,500 square meter, fi ve-story

facility is dedicated to optimizing

the quality and effi ciency of the

development processes for new

automobiles and technologies.

This unique organizational form

enables products and processes

to be verifi ed earlier than ever

before. In the “Cave,” for example,

the feasibility of prototypes can

be verifi ed as early as the initial

concept phase of a product

using

virtual reality techniques. The

design status of the automobile

develops in parallel with prototype

construction. With virtual reality,

the construction of the automobile

can be systematically simulated

long before the fi rst vehicle is

built. This allows problems to be

identifi ed and resolved early on,

and production workfl ows to be

designed even more effi ciently.

Audi

Pre-Series Center

(VSC)

Optimal networking

In the future, the

technologies will be

even more intermeshed

than is the case today.

PHOTOS | ENNO KAPITZA

Electric mobility in a captivating design: The Audi R8 e-tron

will take to the streets as a limited series in late 2012.