Audi 2011 Annual Report Download - page 97

Download and view the complete annual report

Please find page 97 of the 2011 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

It is geared toward conserving resources,

with signifi cant energy savings made

possible by innovative technologies

such as more effi cient robots, new

electric motor-driven welding tongs

and especially light CFRP tools for

body manufacturing. Sometimes even

simple measures can make a crucial

contribution toward achieving a positive

balance: Reprogramming made it

possible for electric hoisting devices

to recuperate as they were lowered

and therefore to feed energy back into

the power grid. And while engines are

running on test stands, they produce

electricity through generators for the

plant power grid.

The process chain during auto-

motive production is energy-effi cient

as well: lightweight construction

materials such as aluminum and

carbon fi ber-reinforced polymer (CFRP)

as well as the use of hot-shaped

steels reduce a car’s weight and there-

fore its consumption throughout its

entire lifecycle.

The Audi balanced mobility concept,

which is designed for energy effi ciency

and environmental conservation, is

increasingly being integrated into the

workforce, according to Dreves:

“The number of suggestions in our

internal improvement system for avoid-

ing emissions and protecting the

environment has increased signifi cantly –

for improving ambient air, for instance,

or preparing rechargeable batteries for

screwdrivers.” Audi balanced mobility

has a consistent focus on people, which

is why the Company is particularly

committed to improving ergonomic

conditions at the workstations.

Clever minds can continuously fi nd

potential for savings where it may not

immediately be obvious – such as in

logistics, where a software program

calculates the optimal use of space in

packaging and containers. By helping to

avoid energy-consuming transport, this

increases the potential for saving energy

to up to 20 percent. Great potential for

saving energy has also been developed

in the area of distribution logistics: Audi

models shipped overseas from Emden

arrive at the port the carbon-neutral way

in the “Eco Plus” commercial transport

trains of DB Schenker Rail – accounting

for a total of 150,000 cars per year. The

additional costs for the green electricity

that is used are borne by AUDI AG. Up

to 70 percent of all cars produced are

transported to their destinations by rail.

Numerous measures are bringing the

Audi Group closer to the goal of climate-

neutral car production. “Emissions

will never be reduced to zero, however,”

Dreves explained. “The unavoidable

emission of CO₂ is therefore increasingly

being off set.”

Regarding the car itself as a product:

Along with making continuous improve-

ments to the effi ciency of conventional

MODEL | IHLENFELD & BERKEFELD GMBH PHOTOS | GERALD BUCHER/TANK MANAGEMENT; AUDI AG

12

75

3

6

4

By 2020, Audi wants to

reduce its site- and

Company-specifi c CO

₂

emissions by 30 percent.

94

_ Responsibility

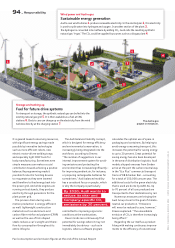

Storage and tanking up

Fuel for future drive systems

For transport or storage, the synthetic natural gas can be fed into the

existing natural gas grid 5. It is then available as a fuel at CNG

stations 6. Electric cars can charge up on the electricity from the wind

turbines directly at the charging station 7.

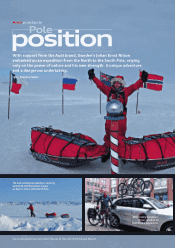

Wind power and Audi e-gas

Sustainable energy generation

Audi’s own wind turbines 1 produce renewable electricity. In the electrolyzer 2, this electricity

is used to split water into hydrogen and oxygen. In another section of the plant 3,

the hydrogen is converted into methane by adding

CO₂

. Audi calls the resulting synthetic

natural gas “e-gas.” The

CO₂

could be supplied by sources such as a biogas plant 4.

Fuel consumption and emission fi gures at the end of the Annual Report

The Audi e-gas

project in miniature.