Chevron 2004 Annual Report Download - page 17

Download and view the complete annual report

Please find page 17 of the 2004 Chevron annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

15

We have designed and implemented comprehensive and disciplined man-

agement systems to help us build organizational capability in operational

excellence and capital stewardship. These systems are aimed at achieving

top operating performance and ensuring that we direct our $10 billion 2005

capital and exploratory budget toward the highest-quality opportunities

with the greatest potential to create future growth and stockholder value.

Operational excellence is a systematic process

for managing our businesses at world-class levels. It is not an independent

process; rather, it is woven into every aspect of our activities. Through opera-

tional excellence, we protect people and the environment and maintain our

reputation as a reliable and efficient energy provider.

Our company’s highest priority is safety, and 2004 was our safest year ever.

Our total recordable incident rate (per 200,000 hours worked) for employ-

ees and contractors improved 14 percent from the previous year, and days

away from work improved 10 percent. Even so, our goal is zero incidents – no

one injured – and we will not be satisfied until we reach it.

Our environmental performance also continued to improve during the year.

Compared with 2003, we reduced the number of oil spills by 14 percent and

the volume spilled by 42 percent. We also made strides in energy conserva-

tion. In 2004, we consumed 2 percent less energy in our operations than in

the previous year, representing savings of $72 million. Since 1992, the year

we began tracking, we have reduced companywide energy use by 24 per-

cent. We also are tracking and managing our greenhouse gas emissions.

As part of this effort, in 2004 we completed a companywide third-party

verification of greenhouse gas emissions.

This subsidiary helps external part-

ners and internal business units find ways to save energy. For example, in

2004, the U.S. Postal Service (USPS) asked CES to complete major energy

efficiency upgrades and a hybrid renewable power plant – including a fuel

cell and two solar electric technologies – at USPS’s largest processing and

distribution facilities in San Francisco, California. The improvements are

expected to lower total annual electricity purchases by $1.2 million and

reduce carbon dioxide emissions by approximately 6,600 tons annually, the

equivalent of planting 1,860 acres of trees.

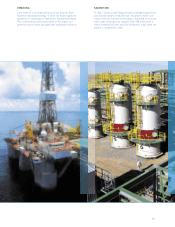

BUILDING THE “PLUS 1”

FOR CAPITAL STEWARDSHIP

We are committed to being the

industry leader in capital stew-

ardship and have a management

system in place to help us identify

the most promising investments

and execute them well. An example

is the $2.2 billion Benguela Belize-

Lobito Tomboco project offshore

Angola, one of our “Big 5” projects.

The development calls for the first

compliant piled tower (CPT) to be

installed outside the U.S. Gulf of

Mexico. Fixed to the sea floor, it

will support drilling and production

facilities and will be the fifth-tallest

structure in the world. The tower is

being fabricated in numerous coun-

tries – on schedule and on budget.

Above: The CPT base template and

foundation piles are en route from

Texas to Angola.