Volvo 2001 Annual Report Download - page 34

Download and view the complete annual report

Please find page 34 of the 2001 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

30

VOLVO IN SOCIETY

approach is shared with all core values –

quality, safety and environment.

A cornerstone in the Volvo environmental

policy is to provide open and factual infor-

mation internally and to our stakeholders.

The information in the annual report is sup-

plemented on the Internet, where detailed

performance data, the Volvo positions and

progress descriptions are provided.

Commitment in the value chain

The environmental aspects of Volvo’s opera-

tions are primarily the emissions from our

products and the production. To manage the

continuous improvement that we promise in

our policy, we use environmental manage-

ment systems in all parts of the value chain,

including both the market organizations and

our suppliers. The progress of obtaining ISO

14001 certificates for our units is steady, and

since Renault Trucks and Mack Trucks are

now included in the Group, new certificates

will be added.

Production and

environment

Global presence, same values,

different conditions

The Volvo Group has production sites on all

continents. The size and conditions of these

sites vary from small-scale production in

Asia to the most modern plants with high

automation in Europe and in North

America. Regardless of size and location, all

production units must comply with our

minimum requirements of environmental

performance and have an on-going improve-

ment program. The requirements include

that energy consumption, waste amounts,

emissions to air and water have to be moni-

tored, as well as specifying maximum emis-

sion levels to air and water. Most plants are

well above the minimum requirements and

show a steady improvement.

Environmental audits

The acquisition of Mack and Renault V.I.

means that 9 new plants are being integrated

in the Volvo Group environmental auditing

and reporting schemes. A thorough due

diligence investigation was performed during

the acquisition process, and action points

were identified. The cooperation with our

new colleagues is proceeding very well, with

mutual learning.

Since 1989, environmental audits have

identified clean-up requirements that have

resulted in corrective measures amounting

to about SEK 52 M. Environmental risk

evaluations of operations are also made in

connection with the environmental audits,

and Volvo has insurance coverage for possible

accidental damage to nearby areas.

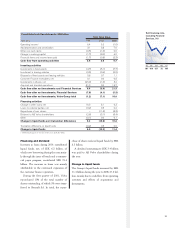

Production performance 2001

At the beginning of 2002, Volvo had a total

of 52 plants for the production of trucks,

buses, construction equipment, marine and

industrial power systems, and aircraft

engines, of which 16 in Sweden. All the

plants have the requisite permits, which in

Sweden covers waste, noise and emissions to

air, water and soil. Two Swedish permits are

to be renewed during 2002.

Since 1996 Volvo reports emission and

consumption data in the annual report, and

in a separate detailed report that is available

on Internet. The 2001 data include the new

Renault and Mack plants and can be found

on page 108. Due to a larger Group, all

parameters show increased absolute values

compared to 2000. However, all parameters

but sulfur dioxide and hazardous waste fol-

low a decreasing trend in relation to net

sales. The hazardous waste parameter is very

dependent on changes in national rules, and

sulfur dioxide emissions have increased due

to limited availability of low-sulfur fuels in

the newly acquired production plants.

97 98 99 00 01

Energy, TWh

Energy/net sales,

MWh/SEK M

1.7 1.8 1.8 1.7 2.5

19.5 16.5 15.6 13.8 14.0

Energy consumption

97 98 99 00 01

Hazardous waste

10.4 10.8 15.6 17.2 19.8

119 101 134 143 109

■ k ton

■ kg/SEK M

97 98 99 00 01

Emissions, ton

Emissions/net sales,

kg/SEK M

0.9 1.1 1.3 1.4 1.7

10.7 10.0 11.4 11.8 9.7

Solvent emissions

97 98 99 00 01

Water, 1.000 m3

Water/net sales,

m3/SEK M

7.3 5.3 6.7 6.1 9.2

84.0 49.1 57.8 51.0 50.8

Water consumption