Volvo 2000 Annual Report Download - page 48

Download and view the complete annual report

Please find page 48 of the 2000 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

46

Environmental impact

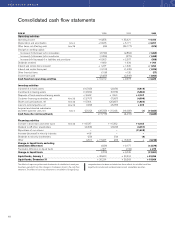

96 97 98 99 00

■ Water, 1.000 m3

■ Water/net sales,

m3/SEK M

6.9 7.3 5.3 6.7 6.1

95.7 84.0 48.4 53.8 47.2

96 97 98 99 00

■ Energy, TWh

■ Energy/net sales,

MWh/SEK M

2.0 1.7 1.8 1.8 1.7

27.3 19.5 16.3 14.5 12.7

96 97 98 99 00

k ton

8.5 10.4 10.8 15.6 17.7

96 97 98 99 00

■ Emissions, ton

■ Emissions/net sales,

kg/SEK M

0.9 0.9 1.1 1.3 1.4

12.0 10.7 9.9 10.7 10.9

▲

To support long-term competitiveness, it is important to integrate environmental strategies

and efforts in all areas, from suppliers to the sales and service organizations. Introducing en-

vironmental management systems in the complete value chain, all based on

the Volvo Group’s Environmental Policy, has been a high priority since 1995.

Suppliers of production material and major dealers are requested to be cer-

tified according to ISO 14001, along with their internal environmental man-

agement development. As of December 31, 2000, 37 of Volvo’s plants and

units were certified in the Volvo Group.

Since 1989, environmental audits have identified clean-up requirements that have resulted

in corrective measures amounting to about SEK 50 M. Environmental risk evaluations of oper-

ations are also made in connection with environmental audits, and Volvo has insurance cover-

ing damage to nearby areas, that may be caused by unexpected discharges.

Production

At the beginning of 2000, Volvo had a total of 45 production plants, of which 16 in Sweden.

All the plants have the requisite permits. The Swedish permit conditions for the production

of trucks, buses, construction equipment, marine and industrial power systems and aircraft

engines cover waste, noise and emissions to air and soil. Three permits will be renewed during

2001. Consumption of energy and water, hazardous waste and emissions of solvents are

reported below. For detailed information see page 106.

Transports

Transports to and from Volvo’s production facilities and distributors cause more substantial

emissions of air pollutants than the operations at the company’s production plants. In order to

encourage environmental improvement measures, Volvo Transport, the Group’s procurement

company for transport services, continuously assesses the environmental work of contracted

transport companies according to a classification system. Every new supplier contract includes

an environmental clause whereby the transport company undertakes to operate in accordance

with the ISO 9000 and ISO 14001 standards.

World-class environmental

management to reduce

environmental risks

Energy consumption Water consumption Hazardous waste Solvent emissions