Kraft 2013 Annual Report Download - page 6

Download and view the complete annual report

Please find page 6 of the 2013 Kraft annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.4

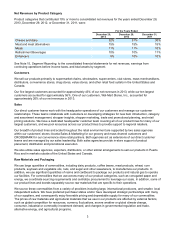

The most significant cost components of our cheese products are dairy commodities, including milk and cheese.

We purchase our dairy raw material requirements from independent third parties, such as agricultural cooperatives

and independent processors. Market supply and demand, as well as government programs, significantly influence

the prices for milk and other dairy products. The most significant cost component of our coffee products is coffee

beans, which we purchase on world markets. Quality and availability of supply, changes in the value of the U.S.

dollar in relation to certain other currencies, and consumer demand for coffee products impact coffee bean prices.

Significant cost components in our meat business include pork, beef, and poultry, which we purchase from domestic

markets. Livestock feed costs and the global supply and demand for U.S. meats influence the prices of these meat

products. Another significant cost component in our grocery products is grains, including wheat, sugar, and soybean

oil.

Our risk management group works with our procurement teams to monitor worldwide supply and cost trends so we

can obtain ingredients and packaging needed for production on favorable terms. Although the prices of our principal

raw materials can be expected to fluctuate, we believe there will be an adequate supply of the raw materials we use

and that they are generally available from numerous sources. Our risk management group uses a range of hedging

techniques in an effort to limit the impact of price fluctuations in our principal raw materials. However, we do not fully

hedge against changes in commodity prices, and our hedging strategies may not protect us from increases in

specific raw material costs. We actively monitor any changes to commodity costs so that we can mitigate the effect

through pricing and other operational measures.

Manufacturing and Processing

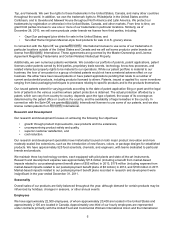

We manufacture our products in our network of manufacturing and processing facilities located throughout North

America. As of December 28, 2013, we operated 36 manufacturing and processing facilities, 34 in the United States

and two in Canada. We own all 36 of these facilities.

While some of our plants are dedicated to the production of specific products or brands, other plants can

accommodate multiple product lines. We manufacture our Beverages products in eight locations, our Cheese

products in 12 locations, our Refrigerated Meals products in nine locations, our Meals & Desserts products in 10

locations, and our Enhancers & Snack Nuts products in eight locations. We maintain all of our manufacturing and

processing facilities in good condition and believe they are suitable and adequate for our present needs. We also

enter into co-manufacturing arrangements with third parties if we determine it is advantageous to outsource the

production of any of our products.

Distribution

As of December 28, 2013, we distributed our products through 39 distribution centers, of which 36 are in the United

States and three are in Canada. We own four and lease 35 of these distribution centers. In addition, third-party

logistics providers perform storage and distribution services for us to support our distribution network.

We rely on common carriers and our private fleet to transport our products from our manufacturing and processing

facilities to our distribution facilities and on to our customers. Our distribution facilities generally accommodate all of

our product lines and have the capacity to store refrigerated, dry, and frozen goods. We assemble customer orders

for multiple products at the distribution facilities and deliver them by common carrier or our private fleet to our

customers. We maintain all of our distribution facilities in good condition and believe they have sufficient capacity to

meet our expected distribution needs.

Competition

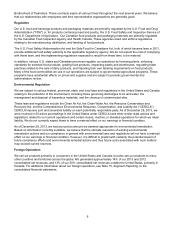

We face competition in all aspects of our business. Competitors include large national and international companies

and numerous local and regional companies. We also compete with generic products and retailer brands,

wholesalers, and cooperatives. We compete primarily on the basis of product quality and innovation, brand

recognition and loyalty, service, the ability to identify and satisfy consumer preferences, the introduction of new

products and the effectiveness of our advertising campaigns and marketing programs, and price. Improving our

market position or introducing a new product requires substantial advertising and promotional expenditures.

Trademarks and Intellectual Property

Our trademarks are material to our business and are among our most valuable assets. Some of our significant

trademarks include A.1., Baker’s, Cheez Whiz, Cool Whip, Country Time, Cracker Barrel, Crystal Light, Grey

Poupon, JELL-O, Kool-Aid, Kraft, Lunchables, MiO, Miracle Whip, Oscar Mayer, Planters, Shake ‘N Bake, Stove