Audi 2013 Annual Report Download - page 26

Download and view the complete annual report

Please find page 26 of the 2013 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200 -

201

201 -

202

202 -

203

203 -

204

204 -

205

205 -

206

206 -

207

207 -

208

208 -

209

209 -

210

210 -

211

211 -

212

212 -

213

213 -

214

214 -

215

215 -

216

216 -

217

217 -

218

218 -

219

219 -

220

220 -

221

221 -

222

222 -

223

223 -

224

224 -

225

225 -

226

226 -

227

227 -

228

228 -

229

229 -

230

230 -

231

231 -

232

232 -

233

233 -

234

234 -

235

235 -

236

236 -

237

237 -

238

238 -

239

239 -

240

240 -

241

241 -

242

242 -

243

243 -

244

244 -

245

245 -

246

246 -

247

247 -

248

248 -

249

249 -

250

250 -

251

251 -

252

252 -

253

253 -

254

254 -

255

255 -

256

256 -

257

257 -

258

258 -

259

259 -

260

260 -

261

261 -

262

262 -

263

263 -

264

264 -

265

265 -

266

266 -

267

267 -

268

268 -

269

269 -

270

270 -

271

271 -

272

272 -

273

273 -

274

274 -

275

275 -

276

276 -

277

277 -

278

278 -

279

279 -

280

280 -

281

281 -

282

282 -

283

283 -

284

284 -

285

285 -

286

286 -

287

287 -

288

288 -

289

289 -

290

290 -

291

291 -

292

292 -

293

293 -

294

294 -

295

295 -

296

296 -

297

297

|

|

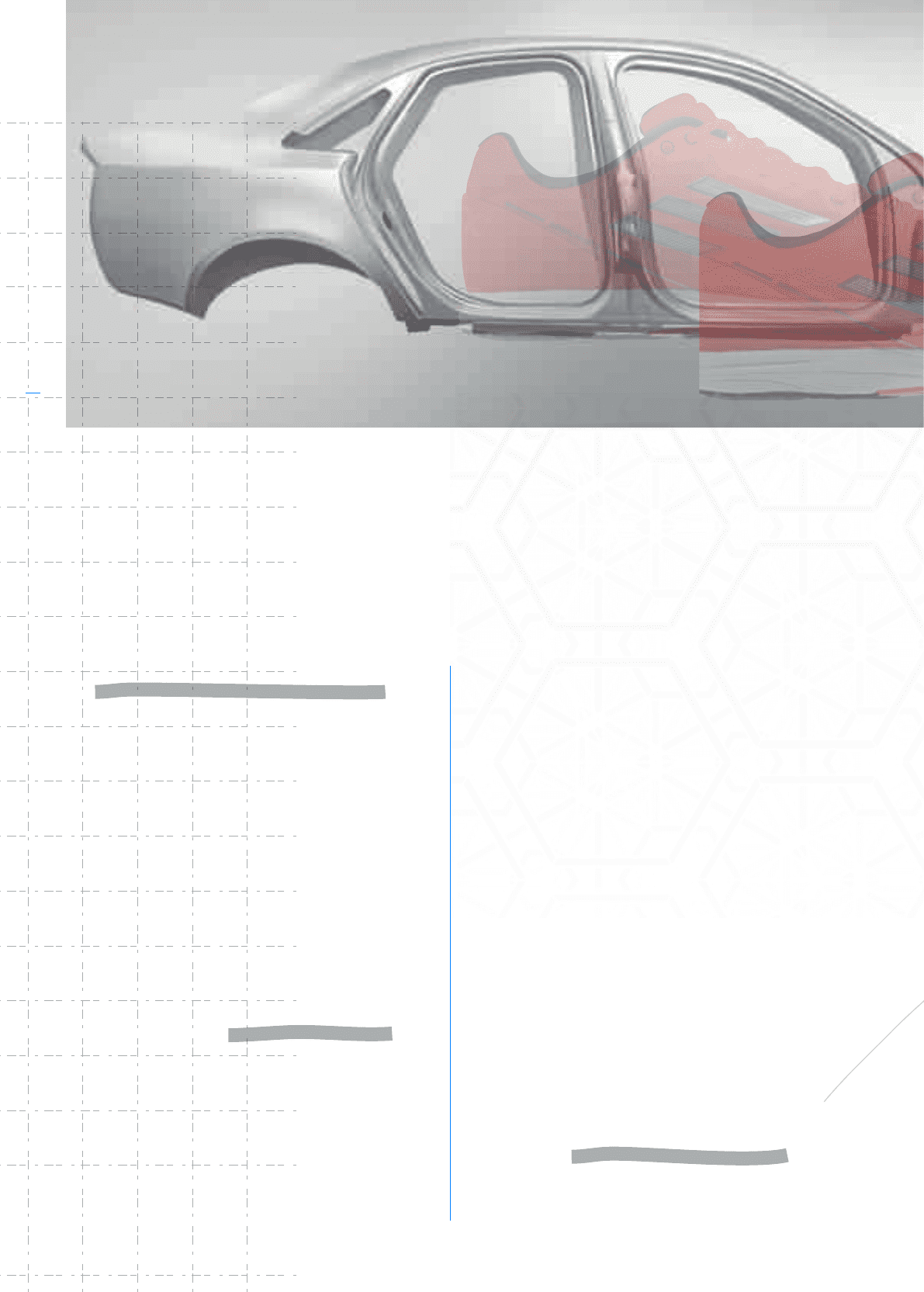

this configuration. The desired material properties can be only

be achieved when multiple plies of this material are cross-lami-

nated – similar to the steel belts of a car tire. Schauerte adds,

however : “Additional requirements with respect to such things

as fracture pattern, temperature resistance, surface quality,

contact corrosion behavior, acoustics or reparability can quickly

reduce a material’s initial high potential for lightweight

construction.” For example, if a very lightweight fiber-composite

component in the finished vehicle has such significant acoustic

disadvantages that a large amount of acoustic insulation is

required, this could oset the weight advantage. And nothing

would be gained.

As is so often the case, the solution is in the details. And in

industrialized, cost-eective manufacturing processes that keep

both weight and price down. Highly engineered, ecient, with

the focus on reduced energy consumption and nearly total

avoidance of waste, as the example of tailored fiber placement

shows. This involves stitching or embroidering carbon or glass

fibers to a substrate. Hardly any waste is produced, and the

fibers are perfectly oriented for the force curves and loads to

which the component will later be subjected.

There are a lot of things that need to be considered when

implementing the lightweight construction philosophy. But as a

pioneer of lightweight construction, Audi will accept nothing

less than an outstanding result. It isn’t the easiest way to go.

But we do our best to make light work of things.

Lightweight construction is one of Audi’s core competences.

“But lightweight construction requires heavy thought,” says

Dr.-Ing. Karl Durst philosophically. He is one of the experts

who make Audi lighter. “Unfortunately, it isn’t enough to

simply use the lightest material, since some lightweight mate-

rials hardly deform at all under load. And that goes against the

concept of safety in body design, since little crash energy would

be absorbed.” The passionate marathon runner, who ensures

that even his running shoes don’t weigh a single gram more

than is necessary, argues in favor of the smart use of composite

materials. “Each material has characteristic properties, advan-

tages and disadvantages. The art lies in combining lightweight

materials in a way that enhances the advantages of the individual

materials while compensating for their respective disadvantages.

We are always anxious to use the right amount of the right

material in the right place,” says Durst.

Audi is therefore increasingly using combinations of steel,

aluminum, magnesium and fiber-reinforced composites of

carbon and glass fibers in lightweight construction. Carbon-fiber-

reinforced polymer is up to 60 percent lighter than high-

strength steel, for example. “Elasticity, high strength and low

density result in above-average mechanical properties com-

bined with great design freedom,” says Dr. Oliver Schauerte,

Head of Technology and Properties Development for Fiber-

Composite Plastics. These materials initially only exhibit their

tremendous properties in the longitudinal direction of their

fibers, not in the lateral direction. Their use would be limited in

PHOTOS : AUDI AG, adidas AG

Fuel consumption and emission figures at the end of the Annual Report

THINK LIGHT

026