Audi 2013 Annual Report Download - page 189

Download and view the complete annual report

Please find page 189 of the 2013 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200 -

201

201 -

202

202 -

203

203 -

204

204 -

205

205 -

206

206 -

207

207 -

208

208 -

209

209 -

210

210 -

211

211 -

212

212 -

213

213 -

214

214 -

215

215 -

216

216 -

217

217 -

218

218 -

219

219 -

220

220 -

221

221 -

222

222 -

223

223 -

224

224 -

225

225 -

226

226 -

227

227 -

228

228 -

229

229 -

230

230 -

231

231 -

232

232 -

233

233 -

234

234 -

235

235 -

236

236 -

237

237 -

238

238 -

239

239 -

240

240 -

241

241 -

242

242 -

243

243 -

244

244 -

245

245 -

246

246 -

247

247 -

248

248 -

249

249 -

250

250 -

251

251 -

252

252 -

253

253 -

254

254 -

255

255 -

256

256 -

257

257 -

258

258 -

259

259 -

260

260 -

261

261 -

262

262 -

263

263 -

264

264 -

265

265 -

266

266 -

267

267 -

268

268 -

269

269 -

270

270 -

271

271 -

272

272 -

273

273 -

274

274 -

275

275 -

276

276 -

277

277 -

278

278 -

279

279 -

280

280 -

281

281 -

282

282 -

283

283 -

284

284 -

285

285 -

286

286 -

287

287 -

288

288 -

289

289 -

290

290 -

291

291 -

292

292 -

293

293 -

294

294 -

295

295 -

296

296 -

297

297

|

|

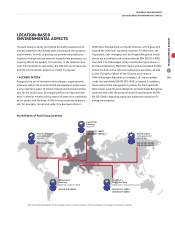

CORPORATE RESPONSIBILITY

LOCATION-BASED ENVIRONMENTAL ASPECTS

MANAGEMENT REPORT

186

A

/

EMISSIONS REDUCTION AND

RESOURCE EFFICIENCY

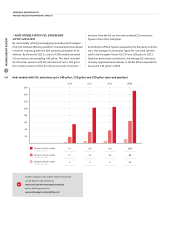

Reducing energy consumption and the related emissions is a

special priority within our Company’s environmental activities.

We pursue an integrated approach and consider not just CO2

emissions generated by a vehicle’s operation, but also raw

materials extraction, the production of component parts and

their assembly, the energy flow in the production facilities,

and recycling. In this connection, we intend to reduce our

specific location-based and company-related CO2 emissions by

25 percent by 2018 compared with the specific figure for 2010.

By 2020 we also aim to cut carbon dioxide emissions from the

energy supply at the Ingolstadt and Neckarsulm locations by

40 percent compared with the specific figure for 2010. Our

long-term vision is of an entirely carbon-neutral automotive

manufacturing process. Starting with the Ingolstadt site, we

aim to roll out this concept gradually across other sites. In

addition to continuously optimizing our processes, we focus

above all on energy-saving measures when planning plant and

buildings and defining logistics processes. Eco-electricity has

been in use at the Ingolstadt site since 2012. This measure

helps to avoid up to 290,000 metric tons of CO₂ a year. The

Brussels location has also been using renewable hydroelectric

power since 2012. Over the period of 2010 through 2018, the

Group is likewise striving for a 25 percent improvement in the

key environmental metrics for energy, fresh water, waste dis-

posal and organic solvents (volatile organic compounds).

In addition to logistics, the production and supply facilities in

particular are significant in terms of permanent efficiency

improvements. For example, the use of ultra-lightweight tools

made mainly from carbon-fiber-reinforced polymer (CFRP) in

body manufacturing helps to save as much as 40 percent in

electricity compared with conventional equipment. Innovative

joining techniques in body manufacturing – such as spot weld-

ing, laser welding and bonding techniques – likewise help to

cut consumption of operating materials and energy.

The modern paint shop at our Győr production location is also

helping us cut back on the amount of energy used. Compared

with the conventional wet separation technology, energy con-

sumption there can be reduced by up to 50 percent with the

help of a dry separation system with air recirculation. Solvent

emissions can even be cut by more than 70 percent. Combined

heat and power, heat and energy recovery systems and the use

of district heating have proven very successful for the Audi Group.

This is exemplified by the new Münchsmünster site, where

particular attention is paid in all areas to the efficient use of

energy. Alongside an ultra-efficient combined heat and power

plant, the waste heat from generating compressed air is fed

back into the heating system, for instance; in addition, process

heat is used for surface heating, and hall ventilation systems

are equipped with heat recovery. The Lamborghini brand, too,

has long been systematically identifying ways of reducing

energy consumption. In July 2012, it completed the new Design

Center for the development of prototypes and pre-production

models. It is equipped with state-of-the-art technology and was

the first building of its kind in Italy to be awarded an “A” energy

rating. This approach was also systematically refined for the

new Logistics Center. Opened in September 2013, this building

has also earned an “A” energy rating.