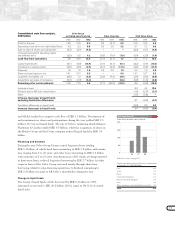

Volvo 1998 Annual Report Download - page 21

Download and view the complete annual report

Please find page 21 of the 1998 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

The Biofidelic Rear Impact Dummy

(BioRID) was unveiled in 1998 following

more than three years of research. The

dummy, which is designed to provide

better knowledge of the ways so-called

whiplash injuries occur and can be

reduced, is equipped with a spine consis-

ting of 24 rigid vertebrae joined by articu-

lated metal welds. These vertebrae are

shaped as torsion bars in the thoracic

region, while movement in the neck

section is determined by a combination of

damping elements and “surrogate

muscles” in the form of longitudinal

cables.

Simulations of molding, performed in a

supercomputer, can now replace practical

experience. As a result, during the initial

phases of development of a new product,

the production processe can be simulated

and tested in a computer, which in turn

means high quality and reduces lead

times and costs.

19

Over the course of years Volvo has displayed a number of advanced concept

vehicles and in 1999 it plans to introduce this technology for tests in buses and

distribution vehicles that will be used in regular traffic for three years to provide

practical experience.

Safety

Safety cannot be compromised within Volvo and always has the highest priority

in all design work. Volvo’s research program has been expanded to include active

safety, biomechanics and behavioural science in addition to traditional passive

safety. There is also a focus on what happens in the course of a collision between

a passenger car and a truck, and when a car hits a pedestrian.

In the area of active safety, development work is taking place mainly in infor-

mation technology (IT) and control systems, the objective being to prevent the

occurrence of accidents. The ability to prevent drivers from falling asleep at the

wheel is a notable example.

Volvo is building a new safety system that will make it possible to conduct

collision tests of cars and commercial vehicles, as well as to simulate accidents

between cars and trucks.

Electronics and control systems

A well-developed, functional structure for the electronic system of a vehicle is

essential for the control systems that are being introduced with the objective of

reducing greenhouse gases, improving safety and increasing mobility. During

1998 Cars and Trucks introduced advanced multiplex electronic systems that can

be supplemented in the future with additional functions such as an integrated

system for the drive line in which the interaction of the engine and the gearbox

is improved to achieve optimal performance.

Virtual vehicles and development processes

Development of a vehicle is a complicated task that involves integrating a large

number of components and systems with many complex interfaces between

components and different suppliers. This has traditionally resulted in long devel-

opment periods and a large number of prototype vehicles. Volvo is increasingly

changing over to the use of IT and simulation tools, which means that both

vehicle and concept can be developed, studied, tested and refined in a computer

– a so-called virtual vehicle – before a vehicle is built. One or two generations of

prototypes can thus be eliminated and, once a prototype is built it will be of

higher quality and much closer to a finished product. As part of this develop-

ment Volvo is conducting research on advanced simulation techniques, including

shaping and flow simulations that will replace wind tunnel tests.

BioRID

Molding