BMW 2015 Annual Report Download - page 47

Download and view the complete annual report

Please find page 47 of the 2015 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

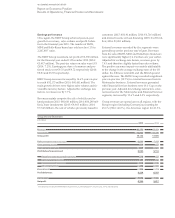

47 COMBINED MANAGEMENT REPORT

Energy consumption – 36.0 %

Water consumption – 31.3 %

Process wastewater – 45.1 %

Non-recyclable waste – 78.9 %

Solvent emissions – 51.4 %

CO2 emissions – 45.7 %

In 2015, the BMW Group reduced the consumption of

resources and emissions per vehicle produced by an

average of 7.0 % compared with the previous year, giving

rise to savings of € 8.2 million. The BMW Group again

cut the energy consumption per vehicle produced by

2.7 % to 2.19 MWh during the period under report (2014:

2.25 MWh). The utilisation of highly efficient, ecologically

sustainable combined heat and power plants (CHPs)

and electricity generated from renewable sources at our

production sites, as well as improved energy efficiency

measures, enabled production-related CO2 emissions

per vehicle produced to be forced down by another 13.6 %

year-on-year to 0.57 tonnes during the period under re-

port (2014: 0.66 tonnes). At 2.24 m³ per vehicle produced

,

Fleet carbon emissions again reduced

The development of sustainable products and services

is an important aspect of the BMW Group’s business

model. CO

2

emissions levels are continually being

re-

duced by incorporating Efficient Dynamics

technolo-

gies in all of the Group’s vehicles. The scope of electri-

fication

within the fleet was further increased in 2015.

These measures form the basis for complying with

le-

gally stipulated CO2 and fuel consumption limits moving

forward. Between 1995 and 2015, the average amount of

CO2 emitted by the Group’s three brands sold in Europe

fell by 39.5 %. In 2015, the BMW Group’s fleet of new

vehicles sold in Europe (EU-28) consumed an average

of 4.7 litres of diesel per 100 km and 5.7 litres of petrol

respectively. CO2 emissions averaged 127 grams per km.

Clean production

The efficient use of resources is an important aspect of

running the business on a sustainable basis. When

applied to all production-related processes, resource

efficiency helps protect the environment and minimise

costs. Since 2006, the consumption of resources and

emissions per vehicle produced has been reduced by an

average of 48.1 %. The individual figures are as follows:

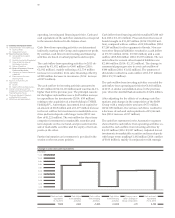

water consumption was slightly higher than one year

earlier, largely due to increased cooling requirements

caused by the hot summer in Germany (2014: 2.18 m³;

+ 2.8 %). At 0.45 m³, the volume of process wastewater

per vehicle produced fell by 4.3 % (2014: 0.47 m³). The

volume of non-recyclable production waste was further

reduced to 4.00 kg per vehicle produced in 2015 (2014:

4.93 kg; – 18.9 %). Solvent emissions were successfully

curtailed by 5.4 % to 1.22 kg per vehicle produced during

2015 (2014: 1.29 kg).

Sustainability along the entire value-added chain

Sustainability criteria are not only a vital aspect of in-

house production, they also play a major role in the

selection and assessment of suppliers as well as in the

field of transport logistics. The active management

of sustainability risks along the supply chain mitigates

compliance and image risks. With this in mind, the

BMW Group has integrated a comprehensive system of

sustainability management in its purchasing processes.

The amount of energy required for transportation world-

wide has continued to rise sharply in recent years. In

order to keep CO2 emissions to an absolute minimum,

the principle “production follows the market” is applied.

In addition, the proportion of CO

2

-efficient modes of

transport is being increased continually.

In the year under report, for instance, the proportion

of goods transported by air freight was significantly re-

duced. At 63.1 %, the proportion of new vehicles leaving

BMW Group plants by rail was maintained at a high

level (2014: 63.3 %).

Competitive thanks to sustainable human

resources policies

In 2015, the BMW Group reinforced its position as one

of the most attractive employers in the world. The

prominent role played in the field of sustainability helps

employees identify with the business and its products.

This strong sense of identification is one of the factors

contributing to the low attrition rate within the BMW

Group, in turn helping to keep personnel recruitment

expenses on the low side.

Social engagement

The BMW Group expended a total of € 39.1 million

(2014: € 34.5 million) for social engagement in 2015, in-

cluding

€ 17.1 million (2014: € 10.2 million) in the form

of donations. The sharp increase in overall expenditure

for social engagement compared to 2014 mainly reflects