BP 2006 Annual Report Download - page 42

Download and view the complete annual report

Please find page 42 of the 2006 BP annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.Continuing response to Texas City incident and inquiries

During 2006, investigations continued into the March 2005 Texas

City explosion. There was also ongoing action on our part to apply the

lessons learned. BP settled a large number of civil suits arising from, and

established a $1.625-billion provision related to, the incident. In terms of

action at the refinery itself, having concluded our own inquiry during 2005

and reached a settlement with OSHA, we have launched a programme in

which we expect to invest an estimated $1 billion from 2006 to 2010 to

improve and maintain the site. At the end of 2006, changes made at

Texas City included: restarting the operations after the shutdown for

Hurricane Rita; extensive mechanical renovation; installing a new flare

system; moving temporary buildings away from specified areas; relocating

more than 400 Texas City workers into a new office building outside the

fence line; commissioning of plant, involving more than 15 million worker

hours to date, refurbishment and safe start-up of a 27-mile steam system;

and implementation of an enhanced total systems training programme.

In January 2007, the company received the report of the BP US

Refineries Independent Safety Review Panel (the panel), which was

chaired by former US Secretary of State James A Baker, III (see Report of

the BP US Refineries Independent Safety Review Panel on page 29).The

panel was established on the recommendation of the US Chemical Safety

and Hazard Investigation Board. Throughout 2006, the panel assessed the

effectiveness of corporate oversight of safety management systems at

BP’s US refineries and the corporate safety culture.

The panel’s report identified deficiencies in process safety performance

at BP’s US refineries and called on BP to give process safety the same

priority that it had historically given to personal safety and the reduction of

GHGs and promotion of alternative forms of energy. In making its findings

and recommendations, the panel’s objective was excellence in process

safety performance, not simply legal compliance. The panel specifically

noted that ‘during the course of its review, it saw no information to

suggest that anyone – from BP’s board members to its hourly workers –

acted in anything other than good faith’.

The panel made 10 recommendations relating to: process safety

leadership; integrated and comprehensive process safety management

system; process safety knowledge and expertise; process safety culture;

clearly defined expectations and accountability for process safety; support

for line management; leading and lagging performance indicators for

process safety; process safety auditing; board monitoring; and industry

leader. The panel’s report in its entirety can be found at

www.bp.com/bakerpanelreport.

The panel acknowledged the measures BP had taken since the Texas

City incident, including dedicating significant resources and personnel

intended to improve the process safety performance at BP’s US

refineries. BP has committed to implement the panel’s recommendations

and will consult with the panel on how best to do this across the US

refineries and to apply the lessons learned elsewhere in its global

operations. As announced in July 2006, there was an increase in spending

at the five US refineries, from $1.2 billion to $1.5 billion a year, with

further increases to $1.7 billion a year for the period 2007 to 2010,

representing a step-up in scale as well as pace.

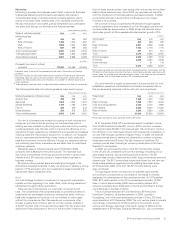

Alaska spills

During 2006, two incidents occurred in our operations at Prudhoe Bay,

Alaska. In March, an undetected leak led to a spill of approximately 4,800

barrels. In August, the eastern part of the field was shut down as a

precaution following the discovery of isolated pitting corrosion that

resulted in a spill of 199 barrels of oil from an oil transit in a pipeline.

Following inspection of the transit lines, production restarted in the

eastern part of the field in 44 days.

Using smart pigs, devices that are run through the inside of the pipeline

to inspect the pipe walls, we have now confirmed sufficient integrity for

current operations. Nonetheless, we have decided to replace the main oil

transit lines (16 miles) in both the eastern and western operating areas of

Prudhoe Bay. In addition, we plan to spend over $550 million (net) over

the next two years on integrity management in Alaska. We have retained

three of the world’s foremost corrosion experts, who will independently

review these programmes.

Action on process safety across BP

Throughout 2006, we continued to implement the improvements initiated

following the Texas City incident and supplemented them with new

measures as necessary. These included inspecting and investing in our

plants; training and development to ensure people have the right skills and

behaviours; and working to ensure we have clear, consistent and rigorous

processes for managing safety. We have earmarked $7 billion for safety

investments over four years to upgrade our US refineries and to repair

and replace pipelines in Alaska. We also appointed a new chairman and

president for BP America Inc. and announced the creation of an external

advisory board to provide expert advice in the US on compliance, safety

and regulatory affairs.

In particular, during 2006 a group-wide programme was introduced

known as the six-point plan to address the following points:

– Removing blow-down stacks and moving temporary buildings away

from potential hazards.

– Conducting major accident risk assessments at plants and acting on

their findings.

– Implementing new group standards that set detailed requirements

on control of work and integrity management.

– Ensuring compliance with applicable laws and regulations.

– Rapidly addressing findings from past audits.

– Building competence in safety and operations through training

and development.

During 2006, the total number of oil spills of one barrel or more from all

of our operations was 417, compared with 541 in 2005 and 1,098 in 1999.

The difference between the reported number of spills in 2005 and 2006 is

principally due to boundary changes, including the disposal of Innovene.

During 2006, we continued to expand our shipping fleet of operated

and time-chartered vessels in order to provide more protection against the

risk of a major oil spill. All vessels on BP business are subject to our

health, safety, security and environmental (HSSE) requirements. The fleet

transformation is ahead of the international requirements for phase-out of

single-hulled vessels. Our international fleet has grown from 52 vessels in

2005 to 57 in December 2006, all of which are double-hulled. We also

have 100 vessels on time charter, of which 83 are double-hulled and three

double-bottomed. In addition, we use spot charter, regional, specialist and

miscellaneous craft. In 2006, we launched SafeShips, an education and

information programme highlighting safety for our seafarers and shore

staff. It covers a wide range of safety-related topics, including risk

assessments, operations safety, best practice and safety by design.

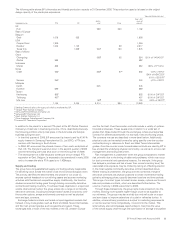

Our operations and the environment

During 2006, we continued working to reduce the environmental impact

of our operations, primarily by reducing our emissions of greenhouse

gases (GHGs) and by implementing processes to drive continuous

improvements in a wide range of other environmental issues. In our

operations since 2001, we have been aiming to offset half of the

underlying GHG emission increases that result from our growing business

through operational efficiency projects. After five years, we estimate that

emissions growth of some 11 million tonnes has been offset by around

6 million tonnes of sustainable reductions.

Our 2006 operational GHG emissions were 64.4 million tonnes (Mte)

of carbon dioxide equivalent on a direct equity basis compared with a

reported figure of 78.0Mte in 2005, of which 11.2Mte related to Innovene

assets divested late in 2005. Our 2006 emissions were therefore some

2.4Mte lower than the comparable 2005 emissions of 66.8Mte (excluding

Innovene’s 2005 contribution).

Our track record of improvement from our ongoing efficiency

programme continues, with reductions of 1.2Mte. The remaining 1.2Mte

decrease comes from the balance of the growth of our business (1.3Mte),

the effect of acquisitions and divestments, temporary operational

variations and reporting protocol changes.

We have taken part in the EU Emissions Trading Scheme since its

launch in January 2005. We began 2006 with 18 participating installations

and, during the year, our BP Solar facility in Madrid also began

participating in the scheme. These 19 installations account for around one-

fifth of our reported 2006 global GHG emissions.

2006 saw the culmination of two years’ work with the launch in

November of a new group practice called the Environmental

Requirements for New Projects. Work on this practice began in 2004

40