BP 2006 Annual Report Download - page 31

Download and view the complete annual report

Please find page 31 of the 2006 BP annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.safely and is producing gasoline, diesel and chemicals products for

the US market.

In parallel, refinery personnel have continued to work to effect the

repair and the safe restart of the remaining process units. Additional

processing facilities were commissioned in the second and third quarters

of 2006. Additional conversion capacity is expected to be brought online

in 2007. BP’s plan is to bring additional sour crude processing facilities

back on-stream in the second half of 2007; these facilities will allow the

processing of additional high-sulphur crude. We expect crude throughputs

to be approximately 400,000 barrels per day by the end of 2007.

The following milestones have been achieved in returning the refinery

to operation with sequenced reconditioning of a multitude of units:

– Major site commissioning involving more than 15 million worker hours

to date.

– Refurbishment and safe start-up of 27-mile steam system.

– Extensive mechanical renovation and the installation of a new

flare system.

– Creation of a new command centre with interactive audio/visual links

to the units, manned 24 hours a day during unit start-up.

– Implementation of a holistic commissioning plan defining behaviours

and accountabilities to deliver safe and successful start-up.

– Implementation of a comprehensive systems training programme,

coupled with safety accountability roll-out plans.

Several other improvements are either complete or under way:

– A new office building for more than 400 Texas City workers

was opened to relocate workers who can work outside our plant

fence line.

– A new flue gas scrubber is being added to the FCC unit. This

$80-million investment will reduce emissions of sulphur and nitrogen

oxide from the refinery.

– A new Employee Services Building (ESB) is under construction. The

ESB will include facilities for learning and development and operations

training departments, including unit training simulators and nine training

rooms, the medical department, some of the site’s security team, the

Incident Management Team and site union official offices.

Construction has started on a new 250 megawatt (MW) steam turbine

power generating plant that will reduce emissions and improve both

energy and operational efficiency. The $100-million unit will be located

next to the existing South Houston Green Power LP co-generation facility

and is expected to boost the total electricity generating capacity located at

the Texas City refinery site to 1,000MW.

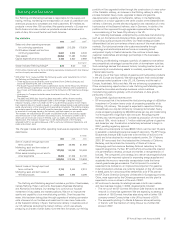

Report of the BP US Refineries Independent Safety Review Panel

On 16 January 2007, having completed its review, the panel issued its

report. The report identified deficiencies in process safety performance

at BP’s US refineries and called on BP to give process safety the same

priority that it had historically given to personal safety and environmental

performance. In making its findings and recommendations, the panel

stated its objective was excellence in process safety performance, not

simply legal compliance. The panel specifically noted that, ‘during the

course of its review, it saw no information to suggest that anyone – from

BP’s board members to its hourly workers – acted in anything other than

good faith.’

The panel made 10 recommendations relating to: process safety

leadership; integrated and comprehensive process safety management

system; process safety knowledge and expertise; process safety culture;

clearly defined expectations and accountability for process safety; support

for line management; leading and lagging performance indicators for

process safety; process safety auditing; board monitoring; and industry

leader. The panel’s report in its entirety can be found at www.bp.com/

bakerpanelreport.

The panel acknowledged the measures BP had taken since the Texas

City incident, including dedicating significant resources and personnel

intended to improve the process safety performance at BP’s US

refineries. BP has committed to implement the panel’s recommendations

and will consult with the panel on how best to do this across the US

refineries and to apply the lessons learned elsewhere in its global

operations.

Other refinery investigations

As a result of its investigation of the Texas City refinery, OSHA conducted

an inspection of BP Products North America Inc.’s Toledo refinery,

beginning in October 2005. On 24 April 2006, OSHA issued citations with

a total penalty of $2.4 million, alleging 39 separate violations of two

different OSHA standards. BP and OSHA have reached a settlement in

principle and are working towards finalizing the documentation.

On 15 November 2006, the Indiana Occupational Safety and Health

Administration (IOSHA) issued the Whiting refinery with three Safety

Orders and Notifications of Penalty alleging 14 separate violations of

the OSHA regulations. The total proposed penalty was $0.4 million. On

7 December 2006, BP and IOSHA met to discuss resolution of the

matter. Discussions to reach a settlement agreement are ongoing.

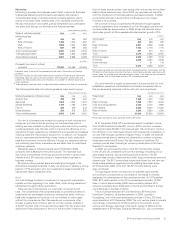

Refining

The company’s global refining strategy is to own and operate strategically

advantaged refineries that benefit from vertical integration with our

marketing and trading operations, as well as horizontal integration with

other parts of the group’s business. Refining’s focus is to maintain and

improve its competitive position through sustainable, safe, reliable and

efficient operations of the refining system and disciplined investment

for growth.

For BP, the strategic advantage of a refinery relates to its location, scale

and configuration to produce fuels from low-cost feedstocks in line with

the demand of the region. Efficient operations are measured primarily

using regional refining surveys conducted by third parties. The surveys

assess our competitive position against benchmarked industry measures

for margin, energy efficiency and costs per barrel. Investments in our

refineries are focused on maintaining and improving our competitive

position and developing the capability to produce the cleaner fuels that

meet the requirements of our customers and their communities.

BP Annual Report and Accounts 2006 29