BMW 2014 Annual Report Download - page 75

Download and view the complete annual report

Please find page 75 of the 2014 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

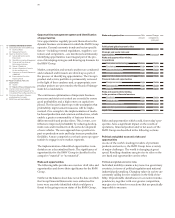

75 COMBINED MANAGEMENT REPORT

Production and technology-related opportunities

In addition to the risks involved, we firmly believe that

the choice of sites for new production facilities also

creates a wealth of opportunities. Selecting a new loca-

tion goes hand in glove with the opportunity to shape

the local environment in a positive way (e. g. job crea-

tion, training, corporate social responsibility (CSR) pro-

jects). Our aim is to continue our commitment to sus-

tainability whenever a new site is selected. We therefore

endeavour to incorporate flagship projects at our pro-

duction sites that have a clear focus on sustainability

(e. g. wind turbines in Leipzig). The option of offsetting

capacities between BMW Group sites is always kept in

mind if production technologies can be employed to

achieve greater efficiency in the use of resources.

Compared to the outlook, efficiency improvements are

unlikely to have a significantly greater impact over

the two-year assessment period than that already incor-

porated in the outlook.

Purchasing risks

Close cooperation between carmakers and automotive

suppliers creates economic benefits on the one hand,

but also raises levels of dependency on the other. The

increasing trend towards modular-based production

with a set of common architectures covering various

models and product lines exacerbates the consequences

of the loss of a supplier or failure to supply on time.

As part of the supplier preselection process, the BMW

Group is careful to ensure that its future business part-

ners meet the same high ecological, social and corpo-

rate governance standards by which the BMW Group is

generally measured. Suppliers are assessed on the basis

of the BMW Group Sustainability Standard, which is

applied throughout our supplier network worldwide.

This set of fundamental principles and standards covers

both production and non-production aspects relevant

for the goods and services provided by suppliers, which

also includes compliance with internationally recognised

human rights and applicable labour and social

stand-

ards. The principal tool for ensuring compliance with

the

BMW Group Sustainability Standard is a

three-

stage s

ustainability and risk management approach com-

prising

a BMW Group-specific sustainability risk filter,

a sustainability questionnaire and a sustainability audit.

In addition, the technical and financial capabilities of

suppliers – especially those supplying for modularbased

production – are continuously monitored during both

the development and production phases of the Group’s

vehicles. Particular attention is paid to the quality of the

parts. In order to attain the level of quality required, it

may become necessary to invest in new technological

concepts or discontinue planned innovations, with the

consequence that the cost of materials could exceed

levels incorporated in the outlook. Supplier sites are as-

sessed for exposure to natural hazards, such as floods

or earthquakes, in order to identify supply risks at an

early stage and implement appropriate countermeasures.

Production problems incurred by suppliers could have

adverse consequences for the BMW Group, ranging

from increased expenditure through to production in-

terruptions and a corresponding reduction in sales

volume.

Raw materials management procedures are in place to

mitigate the risk of a production interruption due to

shortages of supplies of critical raw materials. In order

to reduce supply risks, the BMW Group works hard

to reduce the input of raw materials or to use alternative

raw materials as a substitute.

If purchasing risks were to materialise, they could have

a high impact on the BMW Group’s results of opera-

tions over the two-year assessment period. The level

of

risk attached to supply risks is classified as high,

mainly due to the insufficient availability of raw materials

in Asia.

Risks relating to sales and marketing

Changes in global economic conditions and increasingly

protectionist trends are among the factors that could

result in lower demand as well as fluctuations in the re-

gional spread and composition of sales in terms of

vehi-

cles and mobility services. Risks relating to these

developments can be reduced with the aid of flexible

selling and production processes. At the same time,

in-

creased pressure on selling prices and margins caused

by intense competition on the world’s markets, particu-

larly in Western Europe, the USA and China, requires

constant analysis, including keeping an eye on develop-

ments in grey market volumes from the USA to China.

Selling price and margin risks are determined on the

basis of past experience and changing global economic

conditions, with risk exposures measured using a cash-

flow-at-risk model.

If sales and marketing risks were to materialise, they

could have a

high

impact on the BMW Group’s results

of operations over the two-year

assessment period. The

level of risk attached to sales and

marketing risks is

classified as high.