BMW 2014 Annual Report Download - page 103

Download and view the complete annual report

Please find page 103 of the 2014 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

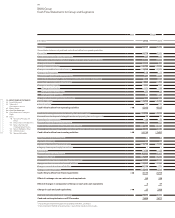

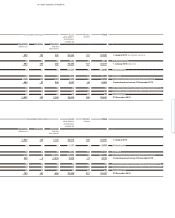

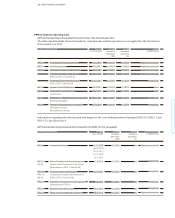

103 GROUP FINANCIAL STATEMENTS

For machinery used in multiple-shift operations, depre-

ciation rates are increased to account for the additional

utilisation.

The cost of internally constructed plant and equipment

comprises all costs which are directly attributable to

the

manufacturing process as well as an appropriate

proportion of production-related overheads. This in-

cludes production-related depreciation and an appro-

priate proportion of administrative and social costs.

As a general rule, borrowing costs are not included in

acquisition or manufacturing cost. Borrowing costs that

are directly attributable to the acquisition, construction

or production of a qualifying asset are recognised as a

part of the cost of that asset in accordance with IAS 23

(Borrowing Costs).

Non-current assets also include assets relating to leases.

The BMW Group uses property, plant and equipment as

lessee on the one hand and leases out vehicles produced

by the Group and other brands as lessor on the other.

IAS 17 (Leases) contains rules for determining, on the

basis of risks and rewards, the economic owner of the

assets. In the case of finance leases, the assets are at-

tributed to the lessee and in the case of operating leases

the assets are attributed to the lessor.

In accordance with IAS 17, assets leased under finance

leases are measured at their fair value at the inception

of the lease or at the present value of the lease payments,

if lower. The assets are depreciated using the straight-

line method over their estimated useful lives or over the

lease period, if shorter. The obligations for future lease

instalments are recognised as other financial liabilities.

Where Group products are recognised by BMW Group

entities as leased products under operating leases, they

are measured at manufacturing cost. All other leased

products are measured at acquisition cost. All leased

products are depreciated over the period of the lease

using the straight-line method down to their expected

residual value. Changes in residual value expectations

are recognised – in situations where the recoverable

amount of the lease exceeds the carrying amount of the

asset – by adjusting scheduled depreciation prospec-

tively over the remaining term of the lease contract. If

the recoverable amount is lower than the expected

residual value, an impairment loss is recognised for the

shortfall. A test is carried out at each balance sheet

date

to determine whether an impairment loss recog-

nised in prior years no longer exists or has decreased.

In these cases, the carrying amount of the asset is in-

creased to the recoverable amount. The higher carrying

amount resulting from the reversal may not, however,

exceed the rolled-forward amortised cost of the asset.

If there is any evidence of impairment of non-financial

assets (except inventories and deferred taxes), or if an

annual impairment test is required to be carried out –

i. e. for intangible assets not yet available for use, intan

gible assets with an indefinite useful life and goodwill

acquired as part of a business combination – an impair-

ment test pursuant to IAS 36 (Impairment of Assets) is

performed. Each individual asset is tested separately

unless the asset generates cash flows that are largely in-

dependent of the cash flows from other assets or groups

of assets (cashgenerating units / CGUs). For the purposes

of the impairment test, the asset’s carrying amount is

compared with its recoverable amount, the latter defined

as the higher of the asset’s fair value less costs to sell and

its value in use. An impairment loss is recognised when

the recoverable amount is lower than the asset’s carrying

amount. Fair value is the price that would be received

to sell an asset in an orderly transaction between

mar-

ket participants at the measurement date. The value in

in years

Factory and office buildings, residential buildings, fixed installations in buildings and outside facilities 8 to 50

Plant and machinery 3 to 21

Other equipment, factory and office equipment 2 to 25

sition or manufacturing cost less scheduled depreciation

based on the estimated useful lives of the assets. De-

preciation on property, plant and equipment reflects

the pattern of their usage and is generally computed us-

ing

the straight-line method. Components of items of

property, plant and equipment with different useful

lives are depreciated separately.

Systematic depreciation is based on the following useful

lives, applied throughout the BMW Group: