Boeing 2006 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 2006 Boeing annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

9

Strong market response to our

committed customer focus,

streamlined production methods

and simplified product line assures

us that we are on the right course.

Our disciplined, measured ramp-up of

airplane production has been integral to

meeting our financial performance goals.

We delivered 398 airplanes for the year, a

37 percent increase over 2005. Revenues

rose 33 percent to $28.5 billion, with

operating earnings of $2.7 billion. Im-

provements to our production systems in

both the Everett and Renton facilities —

including a moving line for the 777 and

continuing Lean improvements to 737

production — have increased efficiency

and reduced costs.

With 1,044 net orders in 2006, Boeing

logged record commercial airplane

orders for the second consecutive year.

Interest in the 787 Dreamliner remained

strong, bringing total orders to 448,

the most successful launch of a new

commercial airplane in Boeing history.

With 729 orders, the 737 family set a

record for sales in a single year.

Response to the new 747-8 was also

excellent, including our first airline order

for the passenger version, the 747-8

Intercontinental. In addition, Boeing

Business Jets announced the sale of the

first 787 and 747-8 VIP models.

On the 787 Dreamliner program, we are

leading our global team through devel-

opment of this revolutionary jetliner. Our

factory partners began parts production

for the 787; the first developmental

wing box was built and successfully

completed structural testing; the first

production wire bundle shipped; our

major systems laboratories became

operational; and we began major assem-

bly on schedule. Also, the 747-400

DreamlifterTM, which will transport major

assemblies for the 787, made its first

flight and began flight testing.

We continue to invest in airplanes

that meet our customers’ needs

now and in the future while contin-

uously improving our production

systems to enhance quality and

efficiency.

Our development programs follow our

view of where the market is going —

point-to-point, high-frequency air travel,

with airplanes that are profitable for our

airline customers and provide the best

experience for the airline passenger. We

are working to enhance responsiveness

to our customers by reducing the time it

takes to resolve operational concerns

and broadening our support capabilities.

At the same time, we continue to drive

efficiencies through our production sys-

tems, and we are on track to increase

production again to more than 440 air-

planes in the next year. The 787 program

is moving forward on schedule, with first

flight planned for 2007. Our goal, as

always, is to provide innovative solutions

that are tailored to our customers’ needs

while running a healthy and profitable

business — and ensuring that we are

here for our customers, both now and

for the long term.

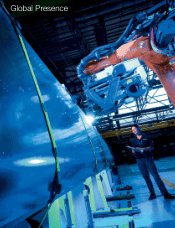

We began implementing the Boeing Production System on the 777 line in 2006.

Enhanced with a moving line, the BPS creates a leaner, more efficient manufacturing

process to build the market-leading 777 jetliner. The 787 Dreamliner will advance pro-

duction even further, with the ambitious goal of reducing final assembly to three days.