Hyundai 2014 Annual Report Download - page 35

Download and view the complete annual report

Please find page 35 of the 2014 Hyundai annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

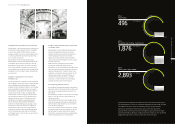

The Asan plant's 10MW rooftop

solar electricity generation system

can reduce up to 5,600 tons of CO

2

emissions per year.

CO2

SOLAR

POWER

5,600t

12.23

million kW

Commitment of

Hyundai Motor

Green technologies for the future

The development of greener vehicles can reduce

greenhouse gas emissions and Hyundai Motor is

developing propriety environmental technologies

with the ultimate goal of zero emissions.

Under the

name of ‘Blue Drive’, Hyundai Motor developed green

technologies which enabled the launch of vehicles

with vastly improved fuel efficiency, innovative

alternative fuel vehicles and clean emission vehicles.

Reducing emissions at manufacturing plants

Hyundai Motor is managing greenhouse gas emissions

from all operation sites including manufacturing

plants, R&D centers and office buildings.

Efforts have been concentrated on the emissions

from three production plants in Korea which account

for 85% of Hyundai Motor’s overall emissions from

domestic operations. At the Ulsan plant, a differential-

pressure power generation facility was installed for

on-site electricity generation. Significant investments

were made to enable the installation of high-

efficiency equipment including low emission boilers.

Thanks to the installation of high-efficiency facilities

and improved productivity, the Asan plant reduced their

greenhouse gas emissions by 8% per unit-produced

compared to the previous year. The Jeonju plant reduced

emissions per unit-produced by 9.1% by investing in high

efficiency equipment, improving production processes and

energy efficiency improvements.

In 2014, a 500kW solar generation plant was installed at

the Namyang Technology Research Center and the staff

improved energy efficiency of testing equipment.

Protecting the environment by recycling resources

Hyundai Motor is promoting resource recycling in all

areas of its operation to strengthen its environmental

management. Hyundai Motor established the first

Automobile Recycling Center in Korea to develop

technologies and processes to minimize the negative

environmental impact from recycling automobiles at the

end of their life cycle. Hyundai Motor decided to support

automobile recycling in Mongolia using its experience

and technological capacity and signed an MOU with the

Mongolia Ministry of Road & Transportation to establish

the Ulaanbaatar ELV Recycling Park (UERP).

Producing clean electricity using solar panels

The Asan plant has a large-scale, solar power plant on its

roof which generates significant amount of clean electricity.

The 10MW generator produces enough electricity to power

3,800 households and reduce CO₂ emission by 5,600 tons per

year, which is equivalent to planting 1.12 million pine trees.

Electricity generated from the solar generator is supplied to

Asan city and near-by regions.

Working with the Emission Trading Scheme

Hyundai Motor has established an internal management

system in response to the implementation of the Emission

Trading Scheme (ETS), a market-based system designed

to deliver greenhouse gas reductions in a growing number

of regions. The Czech Republic plant has already been

operating under the European ETS and Beijing Hyundai

Motor is preparing for the implementation of the ETS in

Beijing, China. The Korean Emission Trading scheme was

launched in 2015 and efforts are ongoing to ensure that

the necessary plants have adequate work processes, work

manual and human resources, organizational capacity and

financial resources to cope with the new policy.

Environmental problems have emerged as a major issue in

determining the future of humanity, Hyundai Motor is dedicated to

minimizing the environmental impact of vehicles throughout their

lifecycle, from development to recycling. Hyundai Motor is also

committed to the development of green energy and is dedicated to

making a contribution to the sustainable future of humanity.

HYUNDAI MOTOR IS

COMMITTED TO FULFILLING

ITS ENVIRONMENTAL

RESPONSIBILITIES TO

ENABLE A SUSTAINABLE

FUTURE FOR MANKIND

HYUNDAI MOTOR COMPANY Annual Report 2014

COMMITMENT OF HYUNDAI MOTOR 68 / 69

Hyundai Motor produced 12.23 million kW

of clean electricity using its rooftop solar

generation system.