BMW 2005 Annual Report Download - page 29

Download and view the complete annual report

Please find page 29 of the 2005 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

28

Quality and environmental management

system receives approval

All of the BMW Group locations adhere to high

standards in the areas of quality and environmental

care. This was confirmed once again in December

2005 with the successful completion of the certifi-

cation audit of the BMW Group production function.

This new certificate, which verifies that the quality

and environment management system complies with

DIN EN ISO 9001 and DIN EN ISO 14001, is valid

for the next three years. This was the second time

that the systems were certified using the so-called

“matrix process”, according to which each location

only has to be audited once within a three-year

cycle. Central production units and control func-

tions of the management system are audited annu-

ally. In 2005, the scope of the certificated area was

extended to include the BMW plant in Thailand

as well as motorcycle development and production.

The BMW Group has never before had a larger

area covered by a single certificate. Specialist exter-

nal auditors (the German TÜV organisation) not only

confirmed a very high standard in terms of quality

and environment care, but also highlighted some

processes as exemplary.

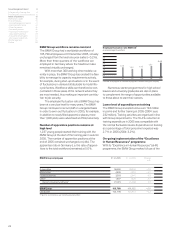

Ongoing measures to reduce emissions and

safeguard resources

A number of key indicators demonstrate the effi-

ciency of the BMW Group’s resources manage-

ment. For example, over the past five years, the

plants in Regensburg and Leipzig have been able

to reduce the amount of solvents used in the com-

pany in total by almost 33% by extending the use

of solvent-free powder varnish technology and ap-

plying a range of other methods. During the same

period of time, the volume of water wasted during

the production process was reduced by almost

29%. Despite the increase in 2005, it has been

possible over the past ten years to reduce energy

consumption by approximately 25% and CO

2

emis-

sions by 20%. These reductions were achieved

by using district heating and combined heat and

power systems, and by applying a range of innova-

tive projects such as district cooling. As an example,

the Projekthaus (Project Building) erected in 2004

as part of the BMW Group’s research and innovation

centre is cooled with groundwater from just below

the ground surface. District cooling has been used

largely to replace traditional electrically operated

cooling equipment. Each year, this avoids emissions

of up to 5,000 tonnes of CO

2

and saves around

8 million kilowatt hours of electricity, equivalent to

the energy consumption of approximately 3,000 pri-

vate households in Germany for one year.

With the emissions trading system in Europe

starting at the beginning of 2005, the BMW Group

was able to boast a close balance between ex-

pected CO2emissions at its European production

locations and emission rights allocated. It is, how-

Group Management Report 8

A Review of the Financial Year 8

The General Economic Environment 11

Review of operations 15

BMW Stock in 2005 38

Financial Analysis 41

--Internal Management System 41

--Earnings performance 42

--Financial position 45

--Net assets position 46

--Subsequent events report 49

--Value added statement 49

--Key performance figures 51

--Comments on BMW AG 52

Risk Management 56

Outlook 60

Volatile organic compounds (VOC) per unit produced

(kg/unit)

3.50

3.25

3.00

2.75

2.50

2.25

2.00

*Structural increase in 2002 due to the new method of calculation in accordance with

the Volatile Organic Compounds Regulation (31st Regulation on the Implementation

of the Federal Immission Control Act)

** Variance to reported figures from previous years due to larger basis of data

*Variance to reported figures from previous years due to larger basis of data

01

3.07

02*/**

3.23

03**

2.88

04**

2.26

05

2.07

Process effluent per manufactured car

(m3/unit)

1.10

1.05

1.00

0.95

0.90

0.85

0.80

0.75

01

1.07

02*

0.92

03*

0.98

04*

0.83

05

0.76