Toyota 2015 Annual Report Download - page 26

Download and view the complete annual report

Please find page 26 of the 2015 Toyota annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.TMMR were merged into one company at the end of 2013 to strengthen the business base and promote

coordination of manufacturing and sales operations. Toyota commenced contract assembly of the Land Cruiser

Prado by Sollers Bussan in Vladivostok in February 2013, but ended production at the end of June 2015. Toyota

commenced complete knock down, or CKD, production of the IMV Fortuner in Kazakhstan beginning in the

spring of 2014.

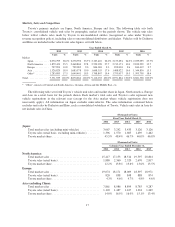

Toyota’s principal European markets are Germany, France, the United Kingdom, Italy, Spain and Russia.

Toyota’s principal competitors in Europe are Volkswagen, Renault, Ford, Opel and Peugeot, as well as Korean

manufacturers Hyundai and Kia.

Asia

Toyota’s consolidated vehicle sales in Asia (including China) in fiscal 2016 was 1,345 thousand units, a

decrease of 9.7% from fiscal 2015.

In light of the importance of the Asian market that is further expected to grow in the long term, Toyota aims

to build an operational framework that is efficient and self-reliant as well as a predominant position in the

automotive market in Asia. Toyota has responded to increasing competition in Asia by making strategic

investments in the market and developing relationships with local suppliers. Toyota believes that its existing

local presence in the market provides it with an advantage over new entrants to the market and expects to be able

to promptly respond to demand for vehicles in the region.

In this region, Toyota has been further strengthening its business foundations by improving its product line-

up, expanding local procurement and increasing production capacities.

As an example of enhancing the product line-up, Toyota began producing IMVs (the Hilux, Fortuner and

Innova) in Thailand, Indonesia, India, the Philippines and Malaysia in 2005 and in Vietnam in 2006.

Furthermore, with increased production capacity, the Thailand plant now produces IMVs for export outside of

Asia, including to Australia and to the Middle East, contributing greatly to the expansion of Toyota’s automotive

business.

As part of Toyota’s efforts to expand business, Toyota Motor Thailand Co., Ltd. commenced production of

hybrid vehicles such as the Camry hybrid in 2009. Toyota also started operation of its second Gateway plant in

2013, expanding production capacity by 80 thousand units in Thailand to 810 thousand units. In April 2015,

Toyota implemented a full model change for IMV models manufactured at its plant in Thailand.

In India, Toyota constructed a second plant with an annual production capacity of 70 thousand units and

commenced production and sales of the Etios compact model designed specifically for the Indian market in 2010.

Furthermore, Toyota increased production capacity in India during 2012 and 2013 to 210 thousand units.

Moreover, Toyota began exporting the gasoline-fueled model of the Etios to South Africa from India in 2012.

In Indonesia, Toyota introduced the Etios and commenced operation of a second plant in Karawang in 2013

in order to meet the diverse customer needs and the expanding market. In 2014, Toyota increased the initial

production capacity of 70 thousand units per year to 120 thousand units per year with the introduction of the Vios

and the Yaris, and also began exporting the Vios to the Middle East. Toyota also constructed a passenger vehicle

engine plant that commenced production in February 2016. In Malaysia, Toyota began production of the Camry

hybrid in March 2015, and is planning to reorganize its production structure there in 2019 by building a new

plant dedicated to passenger vehicles while making the existing plant dedicated to commercial vehicles. In

addition, in 2012 Toyota began production and sales of the Camry hybrid in Taiwan to accommodate the spread

of environmentally friendly vehicles. Moreover, in light of the free trade agreement between the U.S. and Korea,

Toyota began sales of the U.S.-produced Camry in Korea in January 2012.

Toyota’s principal Asian markets are Thailand, Indonesia, India and Taiwan.

21