HTC 2009 Annual Report Download - page 39

Download and view the complete annual report

Please find page 39 of the 2009 HTC annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

7776

CORPORATE GOVERNANCE

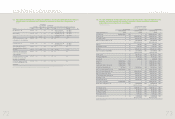

HTC's 2008 greenhouse gas emissions results, focusing primarily on the

organizational boundary of its Taoyuan headquarters, showed that elec-

tricity use was the main source of emissions, which overall amounted to

twenty one thousand metric tons of CO2e (carbon dioxide equivalent).

For 2009, extending the organizational boundary to include each of

HTC's Taiwan offices and its Taoyuan production facility, initial estimates

place its volume of greenhouse gas emissions at thirty thousand metric

tons of CO2e. HTC's inventory of carbon emissions is a further response

to global concerns about greenhouse gases. HTC actively assesses relat-

ed carbon reduction strategies with the goal of reducing emissions of the

greenhouse gas carbon dioxide, thereby helping fulfill its responsibility

as a corporate citizen.

5Green products

In green product R&D, early 2000 marked the introduction of eco-design

processes in which the stages of design, manufacture, use, and even the

end of the product life cycle were examined to find new room for eco-

friendly product design. The thinking behind our eco-designs stretches

from the end-of-the-pipeline treatment directly back to the initial design

stages; one consideration is a reduction in the use of environmentally

harmful substances such as lead, cadmium, hexavalent chromium, and

mercury, etc. Another requirement is increasing the product recycling

rate and the ratio of reusable resources in order to reduce negative envi-

ronmental impacts. A variety of green products have therefore been

developed by using design concepts centered around lower toxicity,

higher energy efficiency, and recyclability. These products meet cus-

tomer needs while conforming with international environmental regula-

tions, enhancing our green competitiveness and fulfilling our ideals of

sustainable development.

>

Low toxicity

By the year 2000 HTC had already instituted controls on

harmful substances in consideration of trends in international

environmental regulations and the related concerns of our

customers. By 2005 it had produced the world's first PDA

phone to conform with the EU's RoHS Directive (Restriction

on the Use of Certain Hazardous Substances in Electrical and

Electronic Equipment Directive). From that time to the pres-

ent, HTC has required that all parts, modules, and materials

delivered to its plants conform with its substances control

checklist. Its control of restricted substances goes beyond the

six controlled substances of the RoHS Directive to include

substances such as formaldehyde, ozone-depleting sub-

stances, and chlorinated paraffin, etc. which have been placed

under control by international environmental laws and regula-

tions as well as by our customers.

>

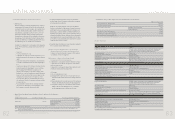

Energy efficiency

In the overall life cycle of an electronic communications prod-

uct, the most energy-intensive stage is the period of use by the

consumer, and energy use during this stage is a major cause of

greenhouse gas production. For that reason we give intense

scrutiny to the question of energy efficiency during the research

and development phase, and all power supplies used with HTC

products must conform to the international energy efficiency

standards below in order to reach our goals for saving energy.

- US EPA Energy Star

- California Energy Commission

- EU Code of Conduct

- EU EuP Directive

In addition, our R&D team has developed outstanding power

management systems that respond to consumers' habitual

modes of use and allow the handset to automatically enter an

energy-saving standby mode, reducing energy use and extend-

ing battery life. Some models also include ambient light sensors

that trigger an automatic LCD backlighting adjustment function,

which in addition to creating more readable displays, also con-

tributes to energy saving goals.

>

Recyclability

HTC makes design-for-recyclability assessments and other

simulations part of its initial research and development phase.

Product disassembly and materials simulations are carried out

to allow calculation of product materials compositions and their

relative recycling rates, while strategies involving materials

labeling, simplification of assemblies, and design for ease of

disassembly provide feedback to R&D units in the form of

design strategies with reference value for R&D processes. At

present, HTC product designs conform with standard product

recycling rates and will continue to do so in the future.

>

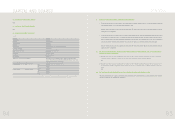

Green packaging

In addition to considerations of visual appeal and packaging

strength requirements, HTC's green packaging concepts also

extend to the development of materials that satisfy the environ-

mental design concepts of low toxicity, low volume, and recy-

clability:

Low-toxicity design

-Packaging materials meet the standards of the EU directive

on packaging materials. Levels of lead, cadmium, mercury,

and hexavalent chromium are all below the limits fixed by

law.

-Packaging materials use no PVCs.

-Packaging materials contain no ODS (ozone depleting sub-

stances) restricted by the Montreal Protocol.

-printing inks are low-volatility or environmental vegetable-

based inks such as soy ink.

Low-volume design

-No use of expanded polystyrene foam (EPS) beads for pack-

ing

-Maximization of stacking volume during shipping to reduce

the amounts of packing materials required

-Improved shock-absorbing packaging, reducing the need for

shock-absorbing packing materials during shipping

Design-for-recycling

-The corrugated board used in mobile phone packaging is

manufactured with more than 90% recycled paper pulp.

-When visual design considerations make the use of virgin

materials unavoidable, all packaging materials meet FSC

(Forest Stewardship Council), PEFC (Programme for the

Endorsement of Forest Certification schemes), or SFI

(Sustainable Forestry Initiative) certification.

6Green building promotion

HTC has already moved to introduce the green building techniques used in

its new headquarters, which are expected to meet the US LEED green build-

ing standards, as criteria to be observed in the building of new plants in the

future, in a move that will help HTC provide environmental, energy-saving,

pleasant, and healthy working environments in the future.

7Promotion of green activities

HTC has chosen the area surrounding its Taoyuan headquarters for green

activities to create clean mountains and clean beaches. Employees have a

chance to get closer to nature and to spontaneously carry out green activi-

ties, showing a concern for the environment that will help protect our living

spaces.

Health and safety management

HTC's basic duty to its employees is summed up in the phrase, "total envi-

ronmental protection and health and safety management, and the provision

and maintenance of a safe and healthy working environment for employ-

ees." This statement also expresses HTC's commitment toward caring for

its employees. In management terms, environmental protection and work-

place health and safety are often two sides of the same coin, which is to say,

harmful substances that create safety hazards are often also environmental

pollutants, and matters that have a negative impact on the environment will

also often be a threat to the safety of employees or production facilities.

HTC draws up an occupational accident prevention plan each year, based

on the status of its health and safety management operations, to prevent,

and to serve as the chief means of prevention, of occupational accidents.

The key points of implementation include observing health and safety laws

and regulations, identifying hazards as a means of lowering risk, creating

standards for management of harmful and dangerous substances, provision

of information on health and safety, and implementing management of con-

tractors. Health and safety risks are reduced through the full participation of

all employees.

Emergency incidents that occur due to human error or natural disaster,

including incidents such as fire, explosions, typhoons, accidental sub-

stance releases, mechanical equipment injuries, contagious disease, or

earthquakes, are handled by HTC in accordance with emergency response

plans, identification of emergency conditions, response measures during

the incident, and after-the-fact critical appraisal and feedback. In addition,

HTC regularly conducts emergency response drills and firefighting exercis-

es in order to minimize the influence of any incidents on employee safety

and health and the assets of the corporation.

HTC has also planned response organizations at different corporate levels

for major contagious diseases such as H1N1 to ensure that all aspects of

the potential problem are covered and dealt with effectively, from handling

of suspected cases, ensuring the health and safety of employees, and sup-

port through sharing of resources.

A healthy working environment

In order to provide a healthier work environment for its employees, HTC has

directed its efforts toward employee health care, wellness promotion, health

management, and employee assistance programs. HTC also provides excel-

lent services in the form of regular medical check-ups, healthy activities,

lectures on health and wellness, testing for those with special conditions,

and psychological counseling, helping employees feel more relaxed and

assured both on and off working hours.

1. Health care, wellness promotion, and health management

In addition to having received OHSAS 18001 certification in the area of

occupational health and safety management systems, HTC also pro-

vides regular medical check-ups, advanced medical check-ups for

high-level officers, special medical testing, general physical exams for

new employees, a resident physician, and lectures on health-related

topics. HTC also provides a variety of facilities to give employees ade-

quate opportunity to relieve stress and improve their mood, such as a

health center, library, gym, massage room, and a multi-sport playing

field, so that employees can enjoy their leisure while also caring for

their own health and developing good exercise habits. Along with

these benefits, HTC has also created a smoke-free workplace and

holds events such as a sports festival and a family day, helping pro-

mote the health of employees and adding variety to their lives, making

the ideal of a happy workplace a dream that can be fulfilled.