BMW 2006 Annual Report Download - page 36

Download and view the complete annual report

Please find page 36 of the 2006 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

35

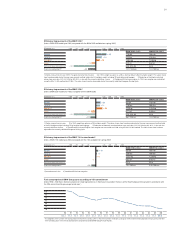

Purchasing structures influenced by model

life-cycles

In 2006, the BMW Group purchased approximately

one half of its bought-in parts in Germany. Across

the rest of Western Europe, the purchase volume

changed in line with production volumes within

the BMW Group. Due to the sales growth of the

BMW 3 Series, the volume of parts bought in from

Central and Eastern Europe increased correspond-

ingly. This was largely attributable to the fact that

suppliers for these model series are located to an

increasing extent in newly acceded countries within

the European Union. The NAFTA market is used

primarily to purchase parts for cars manufactured at

the BMW Spartanburg plant. The production line

change and the BMW X5 model change caused the

purchase volume in this region to fall. The volume

of parts bought in from South America was mainly

attributable to the lower production volume of the

MINI at the Oxford plant, brought about by capacity

expansion measures.

Situation on the commodity markets remains

tense

The high price levels on the raw material markets

once again represented a major challenge for the

group’s purchasing departments in 2006. Signifi-

cantly higher costs had to be paid for supplies of

steel, plastic, aluminium and copper.

The annual average market price of aluminium,

copper and plastic went up in 2006 by 34%, 76 %

and 13 % respectively. Only in the case of steel did

the annual average market price in 2006 remain at

its 2005 level.

The price of industrial raw materials went up by

31% in US dollar terms and by 30 % in euro terms.

The price of non-precious metals increased by 56%

in US dollar terms and by 55% in euro terms. Energy

supplies saw a price increase of 21% and 22% in

US dollar and euro terms respectively.

In the case of precious metals (rhodium, palla-

dium, platinum), purchase price hedges reduced the

impact for the BMW Group of extreme market price

rises. Compared to the previous year, the price of

precious metals relevant for the BMW Group went up

in 2006 by rates of between 27% and 116 %.

Measures were put in place in the area of raw

materials to ensure that additional costs were fairly

spread over the entire added-value chain, with the

BMW Group also bearing its share of the cost.

Al-

though the purchase price predictions of various

institutes have indicated, since the year-end, that

the commodity markets may have eased somewhat,

it is likely that high price levels will persist in 2007.

Purchasing centres help to enhance innovative

strength

The BMW Group’s international network of pur-

chasing centres is committed to the process of

opening up new procurement markets. Focus has

been sharpened in particular on the so-called

“emerging markets”. By realising cost benefits in

these markets, the BMW Group can generate a

positive impact on purchase prices, thus improving

its competitiveness. By analogy to the way that the

BMW Group’s competitiveness is being improved,

suppliers are also encouraged to take better advan-

tage of the cost benefits available on emerging

mar-

kets and to modify their process chains accordingly.

At the same time, measures must be put in place to

ensure that stipulated quality and availability levels

are constantly maintained.

The BMW Group’s purchasing centres are part

of the innovation management process.They inves-

tigate whether the innovative technical solutions

offered by the supply markets meet the requirements

of the BMW Group’s product profile and assess

whether they can make a contribution to the product

creation process. This is an essential factor helping

to enhance the BMW Group’s innovative strength.

Supplier management further optimised

As a manufacturer of premium vehicles, the BMW

Group also attaches great importance to the effi-

ciency of its suppliers. Using a range of targeted

measures, the BMW Group was again able to improve

its supplier management systems in 2006.

The BMW Group fosters relationships with its

suppliers at an early point in the creative process in

Regional mix of BMW Group purchase volumes 2006

in %, basis: production material

Germany

Rest of Western Europe

Central and Eastern Europe

NAFTA

Africa

Asia/Australia

South America 9

10

3

1

3

20

54