LensCrafters 2004 Annual Report Download - page 52

Download and view the complete annual report

Please find page 52 of the 2004 LensCrafters annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

MANUFACTURING

51

VERTICAL INTEGRATION

Over the decades Luxottica Group has vertically

integrated every phase of the production process, as it

saw as at the only way to reach the level of efficiency

suitable for the type of products and services wanted

to offer.

Control of the various phases of production allows the

Group to closely monitor the quality of the products

and processes, introducing innovations, maximizing

synergies and new operating methods.

Supervision of these phases makes it possible to

control and minimize production time and costs, in

order to create the best possible product without

compromising quality in the process.

The accomplishment of these goals is made possible

through the perfecting of every single process,

rigorous quality inspections, and above all, ensuring

that each and every department understands and

fulfills its role in achieving the final results.

This ongoing quest in research and development

provides the plants with the latest equipment and the

best manufacturing methods.

In addition to having state-of-the-art manufacturing

plants, the Group utilizes a centralized system for

monitoring inventory and orders. Each day, the analysis

of this information allows projection of demand, making

it possible to plan production and other necessary

tasks in advance. This is no small advantage for a

group of this size, where the perfect coordination of

supply and demand reduces potential problems in

inventory and in the supply of raw materials.

Bringing together the speed and efficiency of the

manufacturing plants with the precise monitoring of

the market, places Luxottica Group in the best

possible position to efficiently meet customer

requests, adapting to changes in trends in the market

and fashion, both in terms of type and quantity of

product. Such flexibility is a powerful competitive

advantage in such a multifaceted market, where the

ability to address the latest fashion trends is

fundamental.

Over the years, Luxottica Group has brought both retail

and wholesale distribution into its vertically integrated

system. This has allowed the Group to become global

leader in eyewear and to be one of the manufacturers

of premium prescription and sun frames with most

efficient cost control and highest profitability.

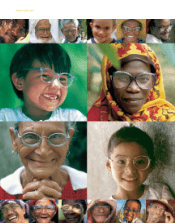

QUALITY: A KEY ASSET

Product quality has always been Luxottica Group’s

main focus and has led to the integration of every

phase of production. Quality is, in fact, the critical

factor in the premium segment for both optometrists

as well as the final consumer.

Quality and process control teams regularly inspect

semi finished products during the various phases of

production: verifying the feasibility of a prototype in the

project design phase, controlling standards across the

spectrum of products during the production phase,

and subsequently checking for resistance to wear and

tear, and optical properties according to various uses.

The manufacturing processes of primary suppliers are

furthermore controlled and certified, including the

materials utilized.

Thanks to the ongoing inspection of the precision and

expertise with which the various phases of production

are carried out, the quality of Luxottica Group’s final

product is always of the highest level. This

fundamental strength of the Group’s products, is

confirmed both by the relationship of trust it enjoys

with independent opticians, as well as the low rate of

returns.