HTC 2008 Annual Report Download - page 47

Download and view the complete annual report

Please find page 47 of the 2008 HTC annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

89

•

Reduction of circuit board surface area

In keeping with the need for slim, lightweight devices

that also have rich functionality, HTC has begun using an

advanced form of multi-layer circuitboard design that

greatly reduces the circuitboard's required surface area.

In 2008, some newly developed models achieved a

reduction in circuitboard surface from 56cm2to 16cm2,

while retaining the same functionality. This type of

advanced design results in a reduction in both weight

and the use of circuit boards, furthermore, helping to

save resources as well as reduce the subsequent burden

on the environment.

•

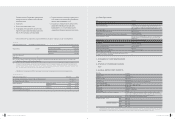

One-piece packaging design methods

HTC makes use of a one-piece cardboard packaging

material made of 100% recycled pulp and that is

recyclable, as shown below, in a clever design developed

by our packaging design experts that use packaging

material to maximum efficiency to reduce its overall

volume. The product is well protected even without the

use of plastic foam packaging, which brings further

reductions in unnecessary packaging in order to achieve

our goals for green packaging.

6. Looking toward the future

In 2008, HTC successfully made environmental concepts such

as lower toxicity, higher energy efficiency, and recyclability part

of its green product design efforts, resulting in the development

of numerous "green" products with highly creative designs and

environmental concepts. HTC's spirit of constant forward

progress in these areas will continue in the future. HTC has set

out even more rigorous environmental standards as design

goals for new products in 2009, and its continued development

and promotion of green products will help it to meet the

standards of international environmental laws as well as

customer demands as it moves ahead toward the vision of

sustainable development.

(5) HTC Foundation

In 2008, HTC and HTC Social Welfare & Charity Foundation or

HTC Education Foundation, to which it donates each year,

engaged in community participation through the following

public interest activities:

1. Continuing support for 200 children from low-income

households in Haiti and the Republic of Ghana for the fourth

consecutive year in cooperation with World Vision Taiwan.

2. Continuing support for 89 children from low-income

households in the Yuli Township of Hualien, Taiwan, for the fifth

consecutive year in cooperation with World Vision Taiwan.

3. Sponsorship of after-school study-program for 300 children

from low-income households, for the fifth consecutive year in

cooperation with the Chinese Christian Relief Association.

4. Contributions by the Foundation and HTC of NT$20 million

each to disaster relief in Sichuan Province for donation to

rebuilding projects in disaster regions. Employees have also

donated nearly NT$ 4 million for construction of the Chadian

Township elementary school in Mian County, Shanxi.

5. Provision of NT$ 3 million for assistance to Myanmar hurricane

disaster relief in cooperation with the Ling Jiou Mountain

Buddhist Foundation.

6. Provision of scholarships for 1,000 students for the second

consecutive year at six schools in China's remote northwest

regions and Qinghai Province.

7. Provision of tuition and board year-round for 100 needy senior

high school students for the second consecutive year with

outstanding records in China's Ningxia and Liaoning Provinces.

8. Sponsorship of Good Deed Representative Yin Guanghua for the

third consecutive year in giving character-building lectures at

hundreds of schools and prisons around the country.

9. Provision of assistance for the second consecutive year to the

Rehabilitation Hope Project at the Development Center for the

Spinal Cord Injured.

10. In addition, HTC provides long-term support for youth

education and character-building organizations for the fifth

consecutive year, including the Champions Education

Association and the Rainbow Family Life Education Association.

11. Provision of free Carnegie motivation training course to school

teachers through the "Pan Shi Education Project" for a

cumulative total of 20,000 persons and teacher character

education training for a cumulative total of 15,000 persons

throughout Taiwan. In 2008 we promoted the "Character

Building Schools" for 16 schools in Taoyuan.

12. Contribution to establishment of a Character & English Institute

in Hualien County by providing full sponsorship for attendance

for all 4th-grade elementary students in Hualien County at a

five-day four-night camp for character building and English

learning. HTC contributes tens of millions of New Taiwan

Dollars in sponsorship for all operating and upkeep costs, while

also participating in development of courses that provide

English teaching to minorities and residents of remote districts.

13. Sponsorship of children from low income families, in the

Taoyuan County English Village.

14. Continuing promotion of HTC's "Character Township" plans for

public servants in 5 townships, providing training to a

cumulative total of 2,000 visits.

IV. CO RPO RATE GOVERN AN CE

88

2. Energy efficiency

In the overall life cycle of an electronic communications

product, the most energy-intensive stage is the period of use by

the consumer, and energy use during this stage is a major cause

of greenhouse gas production. For that reason we give intense

scrutiny to the question of energy efficiency during the research

and development phase, and all power supplies used with HTC

products must conform to the international energy efficiency

standards below in order to reach our goals for saving energy.

> US EPA Energy Star

> California Energy Commission

> EU Code of Conduct

In addition to formulating standards for power supply energy

use, our R& D team has developed outstanding power

management systems that respond to consumers' habitual

modes of use and allow the handset to automatically enter an

energy-saving standby mode, reducing energy use and

extending battery life. Some models also include ambient light

sensors that trigger an automatic LCD backlighting adjustment

function, which in addition to creating more readable displays,

also contributes to energy saving goals.

3. Recyclability

The primary goal of design-for-recyclability is meeting the

requirements of international environmental regulations with

regard to recycling rates. HTC's standards for product recycling

rates in 2008 used assessment criteria taken from the EU's

Waste Electrical and Electronic Equipment (WEEE) Directive. For

the above reasons, HTC makes design-for-recyclability

assessments and other simulations part of its initial research

and development phase. Product disassembly and materials

simulations are carried out to allow calculation of product

materials compositions and their relative recycling rates, while

strategies involving materials labeling, simplification of

assemblies, and design for ease of disassembly provide

feedback to R&D units in the form of design strategies with

reference value for R&D processes. These procedures mean that

recycling operations can be carried out smoothly during the

disposal phase at the end of a product's useful life cycle,

enhancing the benefits of recycling and reducing the impact on

the environment.

4. Green packaging

In addition to considerations of visual appeal and packaging

strength requirements, HTC's green packaging concepts also

extend to the development of materials that satisfy the

environmental design concepts of low toxicity, low volume, and

recyclability:

> Low-toxicity design

•

Packaging materials meet the standards of the EU

directive on packaging materials. Levels of lead,

cadmium, mercury, and hexavalent chromium are all

below the limits fixed by law.

•

Packaging materials use no PVCs. Packaging

materials contain no ODS (ozone depleting

substances) restricted by the Montreal Protocol.

•

Printing inks are low-volatility or environmental

vegetable-based inks such as soy ink.

> Low-volume design

•

No use of expanded polystyrene foam (EPS) beads for

packing

•

Maximization of stacking volume during shipping to

reduce the amounts of packing materials required

•

Improved shock-absorbing packaging, reducing the

need for shock-absorbing packing materials during

shipping

> Design-for-recycling

•

Manufacture of corrugated board with more than 90%

recycled pulp

•

When visual design considerations make the use of

virgin materials unavoidable, all packaging materials

meet FSC

1

(Forest Stewardship Council), PEFC

2

(Programme for the Endorsement of Forest

Certification schemes), or SFI

3

(Sustainable Forestry

Initiative) certification.

1

FSC Forest Stewardship Council

;

http:www.fsc.org

2

PEFC Programme for the Endorsement of Forest Certification

;

http:www.pefc.org

3

SFI Sustainable Forest Initiative

;

http://www.sfiprogram.org/

5. Eco-design cases

HTC employs a variety of eco-design strategies during R&D

stages, resulting each year in the development of a wide variety

of green products:

•

Environmental surface treatment methods While a

lustrous metallic finish is a necessary part of the

appearance of HTC products, it cannot interfere with their

radio frequency functions and electromagnetic

compatibility. HTC thus uses the NCVM (non-conductive

vacuum metallization) surface treatment process, which

meets the needs of both visual design and

telecommunications functions, and in addition, the

process reduces the use of nickel plating, contributing to

clean manufacturing processes and helping reduce the

problem of some users' skin allergy to nickel.

2OO 8 HTC AN N UAL REPO RT

'0 8A R_ HT C/ 英文版* NEW 05/ 21/ 20 09 11: 02 頁面 8 8