Audi 2015 Annual Report Download - page 179

Download and view the complete annual report

Please find page 179 of the 2015 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

CORPORATE RESPONSIBILITY

LOCATION-BASED ENVIRONMENTAL ASPECTS

>> 179

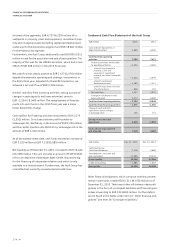

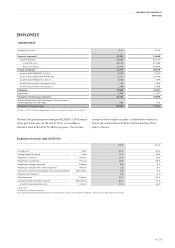

Environmental structural data 1)

2015 2014

Direct CO2 emissions 2) t 220,306 199,584

Energy consumption 3) GWh 2,707 2,543

VOC emissions 4) t 1,774 1,959

Fresh water purchased m³ 4,044,587 3,867,569

Volume of waste water m³ 2,695,054 2,624,488

Total volume of waste 5) t 87,872 82,285

of which recyclable waste t 73,775 68,279

of which disposable waste t 14,097 14,006

Metal waste t 353,741 345,855

1) Ingolstadt, Neckarsulm, Brussels, Győr, Sant’Agata Bolognese and Bologna plants;

2015 figures provisional

2) This figure is made up of CO2 emissions generated by the use of fuel at the plant, and CO2

emissions produced by the operation of test rigs.

3) Total electrical energy, heat, fuel gases for production processes and externally supplied

refrigeration

4) VOC emissions (volatile organic compounds): This figure is made up of emissions from the

paint shops, test rigs and other facilities.

5) Including non-product-specific waste

In the 2015 fiscal year, new projects and measures additional-

ly contributed to emissions reduction and resource efficiency.

At the Ingolstadt site, a modern plug-in hybrid locomotive has

been in service for rail shunting operations since November

2015. It brings a significant reduction in emissions compared

with conventional locomotives. We have also improved energy

efficiency in body manufacturing by introducing modern con-

trol technology for our robots. Since January 2015, electrical

energy has been sourced exclusively from renewable sources in

Münchsmünster. This has already been the case in Ingolstadt

since 2012.

Energy-saving processes are also in the spotlight at the

Neckarsulm site. Highly energy-efficient Automated Guided

Vehicles are used in the production of the Audi R8 at the

new Böllinger Höfe facility.

Since fall 2015, Audi Hungaria has covered around 60 percent

of our Hungarian site’s heat requirements from the new geo-

thermal energy plant near Győr. It offers the prospect of cut-

ting CO2 emissions at the location by a further 19,800 metric

tons annually.

In Sant’Agata Bolognese (Italy), Automobili Lamborghini S.p.A.

put a new CCHP (combined cooling, heat and power) plant into

operation in the 2015 fiscal year. In addition, our Italian

subsidiary has been utilizing surplus waste heat from a nearby

biogas plant since 2015. Both measures bring about a signifi-

cant reduction in CO2 emissions.

Environmental protection concerns were furthermore accom-

modated when creating the new Audi driving experience center

in Neuburg. Thanks to the use of waste heat from neighboring

industrial establishments and of green power from hydroelec-

tric power stations, the power and heat supply is carbon-neutral.

Audi was awarded a Gold certificate for sustainable construc-

tion by the DGNB (German Sustainable Building Council) for its

customer building.

/EMISSIONS TRADING

The third trading period in the EU-wide trading of CO2 emission

rights has been running since 2013. This phase ends in 2020.

The Ingolstadt, Neckarsulm, Brussels (Belgium) and Győr

(Hungary) locations are subject to EU emissions trading rules.

Unused certificates from past trading periods were carried

forward to the third trading period to minimize the risk of a

future shortfall in cover, through which the Audi Group would

potentially incur costs.

/ACCREDITATION

Alongside using innovative technologies, organizational

measures within the environmental management systems are

a very important aspect for the Audi Group. All European auto-

motive plants of the Audi Group are accredited under the

European Union’s EMAS (Eco-Management and Audit Scheme),

which goes well beyond the minimum standards required.

Furthermore, the Ingolstadt, Győr (Hungary) and Sant’Agata

Bolognese (Italy) plants are accredited under the globally valid

DIN EN ISO 14001 standard. The same accreditation has been

obtained for the new location in in São José dos Pinhais (Brazil)

and for the motorcycle plant in Bologna (Italy) as well as for

the Volkswagen Group production locations that we use in

Bratislava (Slovakia), Martorell (Spain) and Aurangabad (India).

The Changchun and Foshan plants of the associated company

FAW-Volkswagen Automotive Company, Ltd., Changchun (China),

have likewise obtained accreditation to DIN EN ISO 14001.

The environmental management systems for the Ingolstadt,

Neckarsulm, Győr, Brussels (Belgium) and Sant’Agata Bolo-

gnese locations also meet the requirements of DIN EN ISO

50001, which sets particularly high standards for continuous,

systematic reductions in energy consumption.