Volvo 2003 Annual Report Download - page 27

Download and view the complete annual report

Please find page 27 of the 2003 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

25

Future fuels and energy efficiency

Major changes regarding the use of energy

sources, fuels and vehicle powertrains, are

slow processes that must be based on

extensive investigations involving many dif-

ferent aspects. A few of the most important

are possible energy supply, energy efficiency

and greenhouse gas emissions, all of them in

a well-to-wheel perspective.

The Volvo Group has found that DME (Di-

Methyl Ether) has a very strong case as a

long term vehicle fuel, derived both from fos-

sil and renewable sources. The results also

show that the diesel engine will play a vital

role in future drive trains, due to its inherent

energy efficiency and ultra low emission

potential, also together with fuels derived

from renewable sources.

The development of the second genera-

tion heavy duty DME vehicle technology has

continued successfully and a prototype truck

will be presented by Volvo during 2004.

The focused environmental agenda

defines far-reaching objectives for energy

efficiency also in the production processes.

The organization is now being challenged on

how to achieve substantially decreased CO2

emissions in the most cost-effective way.

The production impact

The Volvo Group has production sites on all

continents. Minimum environmental perform-

ance and an ongoing improvement programs

are a requirement at all plants, and have

been followed up by regular audits since

1989. The environmental audits identify en-

vironmental risks and possible need for

clean-up or other corrective actions, with a

follow-up to ensure that these are promptly

conducted. The Volvo Group has insurance

coverage for possible accidental damage to

nearby areas.

At the beginning of 2004, Volvo had a

total of 48 plants for the production of trucks,

buses, construction equipment, marine and

industrial power systems, and aircraft

engines, of which 16 in Sweden. All the

plants have the requisite permits, which in

Sweden cover waste, noise and emissions to

air, water and soil. Two Swedish permits are

to be renewed during 2004 due to a future

increase in production volume.

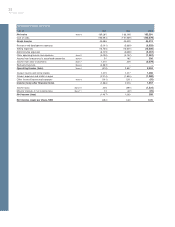

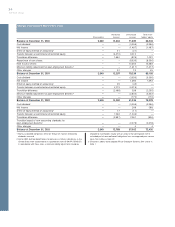

Consumption of energy remained at

roughly the same level as in 2002 but a slight

decrease can be seen in the emissions of

CO2and NOxduring 2003. The total water

consumption also decreased during 2003.

The program to increase resource efficiency

is starting to give effect also in the emission

values. Although using low sulphur content

fuels when possible, an increase in the use

of heating oil caused an increase in sulphur

dioxide emissions compared to 2002. A total

increase in production volumes caused a

minor increase in solvent emissions and

hazardous waste.

99 00 01 03

1. 8 1.7 2.6 2.6

Energy consumption

Energy, TWh

Energy/net sales

MWh/SEK M

15.6 13.8 14.3 14.9

99 00 01 03

6.7 6.1 9.2 8.6

Water consumption

Water, Mm3

Water/net sales

m3/SEK M

57.8 51.0 50.9 49.1

99 00 01 03

15.6 17.2 20.3 21.6

Hazardous waste

k ton

kg/SEK M

13 4 14 3 112 124

99 00 01 03

1.3 1.4 1.8 2.0

Solvent emission

Emissions, k ton

Emission/net sales

kg/SEK M

11.411.8 10.1 11.2

02

2.6

14.5

02

9.2

52.0

02

20.5

116

02

1.9

10.7

Detailed data is found in the adjoining

diagrams and in the table on page 93.