Volvo 2003 Annual Report Download - page 26

Download and view the complete annual report

Please find page 26 of the 2003 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

24

Business Areas

Managing values

The corporate values of quality, safety and

environmental care are naturally immersed in

the daily operations of the Volvo Group.

Quality and environmental management sys-

tems are used in all parts of the organization

as the means for addressing responsibility

and objectives. The Group policies and a

common network of environmental auditors

ensure that the Group guidelines and objec-

tives are addressed. During 2003 the

Group’s business areas finalized introduc-

tion of environmental management systems

in most operations. All but two production

sites are now certified. Some market organi-

sations still remain and projects are ongoing

for all other operations with certification

planned for 2004.

Quality issues

In product development, all business areas

and business units use a well structured

process with quality gates and milestones

specifying the requirements that have to be

fulfilled before a project is allowed to continue.

Safety and environmental requirements are

also key parameters in the process.

The focus on product quality in the devel-

opment process as well as in the interface

with the customer has led to improved results

in customer satisfaction measurements.

Safety development

One important safety requirement is high

product quality – the vehicles and engines

must function reliably, and as the user

expects. Other aspects of safety are to pre-

vent accidents from happening, and when

the accident is unavoidable, how to minimize

the injuries for the driver, the passengers and

people nearby.

A dedicated work to integrate the Volvo

safety features and concepts into the new

product lines at Volvo CE demonstrates how

a good workplace with easy entrance and

good visibility for the operator adds to high

safety.

A focused environmental agenda

During 2002, improved energy efficiency

and lower emissions were defined as the

focused environmental agenda for the entire

Volvo Group, and objectives for the coming

tree-year period were developed.

Fuel efficiency is the main interest of all

our customers, with its direct link to the oper-

ating costs of the business. Improved total

fuel efficiency is also the most rewarding way

to decrease carbon dioxide (CO2) emissions.

At the same time to improve ambient air

quality, increasingly stricter emission regula-

tions put pressure on the engine develop-

ment to decrease mainly nitrogen oxides

(NOx) and particle emissions. Unfortunately,

higher fuel efficiency normally means higher

emissions of NOx, a physical fact resulting

from higher combustion temperatures. This

balance is the challenge for all the Volvo

Group business areas.

The recent product launches demonstrate

how the stricter emission requirements have

been met with highly competitive fuel effi-

ciency, like the Volvo CE product lines. In

many cases also decreased fuel consump-

tion, for example, Volvo Penta’s new medium-

heavy marine diesel engines, D4-210 and

D6-310, and the new D3, a future alternative

to outboard engines, are combined with sub-

stantially lower emissions as well as advan-

tages in terms of weight and noise levels.

The key to the success is a close collabora-

tion between engine development and each

application, to ensure the right combination

of engine, transmission, chassis and body.

The I-shift transmission used in the Volvo

Trucks is an excellent example of this inte-

gration.

M ore inform ation on the

Internet

More detailed environmental information can be

found at www.volvo.com.

You will find:

Policy documents, brochures, environmental data

- products and production, emission legislation,

product safety examples and training material.

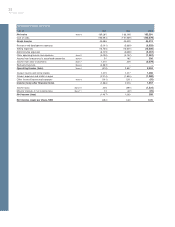

0.16

0.14

0.12

0.10

0.08

0.06

0.04

0.02

0.00012345678

Particles g/ KWh

NOx g/ KWh

US ´02 Euro 3

Current

Euro 4Euro 5

US 07-11

Euro 2

Emissions standards for trucks and buses

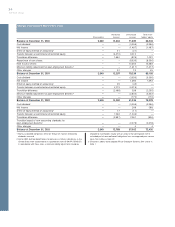

Fossil

Renewable

Diesel (crude

oil) [1]

DME (natural

gas) [1]

CNG (natural

gas) [2]

Hydrogen (EU

mix electr.) [3]

DME (wood)

[1,4]

Biogas

(sewage) [2]

RME (rape

seed) [1]

Ethanol (culti-

vated crop) [2]

Energy efficency, % 10 20 30

GW P g/kWh 400 600 1200

Energy efficency and GWP – Global

Warming Potential, “well-to-wheel”

DME = Dimethyl ether

RME = Rape methylester

BM = Biomass

[1] Diesel process

[2] Otto process

[3] Fuel cell hybride

[4] Wood via black liquor