Tyson Foods 2011 Annual Report Download - page 12

Download and view the complete annual report

Please find page 12 of the 2011 Tyson Foods annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

12

all or substantially all of our assets and other corporate transactions. This concentration of ownership may also delay or prevent a

change in control otherwise favored by our other stockholders and could depress our stock price. Additionally, as a result of the Tyson

family’s significant ownership of our outstanding voting stock, we rely on the “controlled company” exemption from certain corporate

governance requirements of the New York Stock Exchange.

ITEM 1B. UNRESOLVED STAFF COMMENTS

None

ITEM 2. PROPERTIES

We have production and distribution operations in the following states: Alabama, Arkansas, Georgia, Illinois, Indiana, Iowa, Kansas,

Kentucky, Louisiana, Mississippi, Missouri, Nebraska, New Mexico, New York, North Carolina, Oklahoma, Pennsylvania, South

Carolina, Tennessee, Texas, Virginia, Washington and Wisconsin. We also have sales offices throughout the United States.

Additionally, we, either directly or through our subsidiaries, have sales offices, facilities or participate in joint venture operations in

Argentina, Brazil, China, the Dominican Republic, Hong Kong, India, Ireland, Japan, Mexico, the Netherlands, Peru, the Philippines,

Russia, South Korea, Spain, Sri Lanka, Taiwan, Thailand, the United Arab Emirates, the United Kingdom and Venezuela.

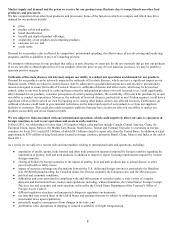

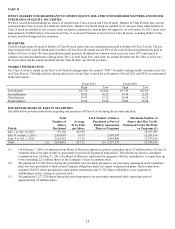

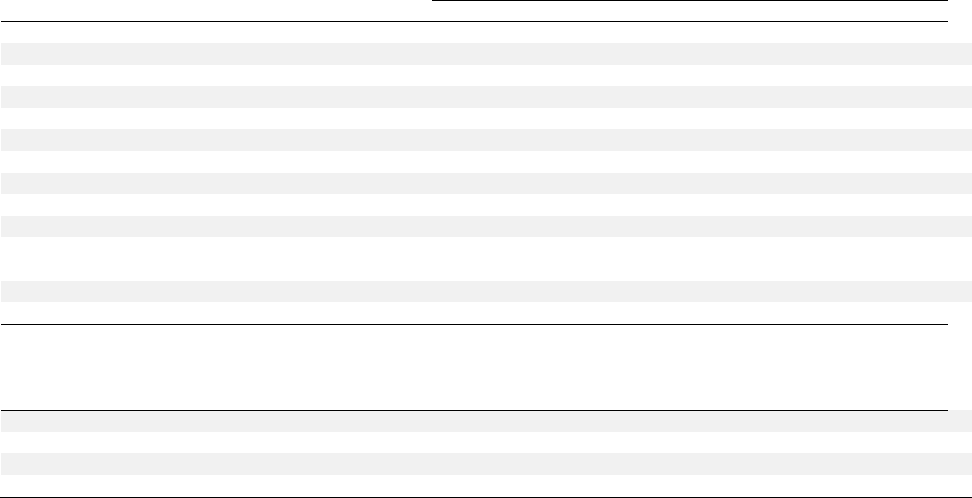

Number of Facilities

Owned

Leased

Total

Chicken Segment:

Processing plants

60

1

61

Rendering plants

15

-

15

Blending mills

2

-

2

Feed mills

41

2

43

Broiler hatcheries

62

10

72

Breeder houses

508

783

1,291

Broiler farm houses

809

926

1,735

Beef Segment Production Facilities

12

-

12

Pork Segment Production Facilities

9

-

9

Prepared Foods Segment Processing Plants

22

1

23

Distribution Centers

11

5

16

Cold Storage Facilities

65

12

77

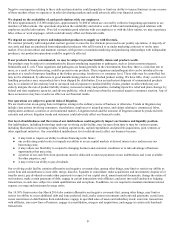

Capacity(1)

Fiscal 2011

per week at

Average Capacity

October 1, 2011

Utilization

Chicken Processing Plants

46 million head

92%

Beef Production Facilities

175,000 head

81%

Pork Production Facilities

448,000 head

89%

Prepared Foods Processing Plants

45 million pounds

85%

(1) Capacity based on a five day week for Chicken and Prepared Foods, while Beef and Pork are based on a six day week.

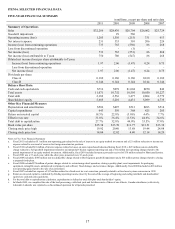

Chicken: Chicken processing plants include various phases of slaughtering, dressing, cutting, packaging, deboning and further-

processing. We also have 17 pet food operations, which are part of the Chicken processing plants. The blending mills, feed mills and

broiler hatcheries have sufficient capacity to meet the needs of the chicken growout operations.

Beef: Beef plants include various phases of slaughtering live cattle and fabricating beef products. Some also treat and tan hides. The

Beef segment includes three case-ready operations that share facilities with the Pork segment. One of the beef facilities contains a

tallow refinery. Carcass facilities reduce live cattle to dressed carcass form. Processing facilities conduct fabricating operations to

produce boxed beef and allied products.

Pork: Pork plants include various phases of slaughtering live hogs and fabricating pork products and allied products. The Pork

segment includes three case-ready operations that share facilities with the Beef segment.

Prepared Foods: Prepared Foods plants process fresh and frozen chicken, beef, pork and other raw materials into pizza toppings,

branded and processed meats, appetizers, prepared meals, ethnic foods, soups, sauces, side dishes, pizza crusts, flour and corn tortilla

products and meat dishes.

Our Dynamic Fuels joint venture produces renewable synthetic fuels targeting the renewable diesel and jet fuel markets. Construction

of production facilities was completed in late fiscal 2010, and initial production began in October 2010. Dynamic Fuels operates one

plant with designed annual capacity of 75 million gallons.