Audi 2014 Annual Report Download - page 36

Download and view the complete annual report

Please find page 36 of the 2014 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200 -

201

201 -

202

202 -

203

203 -

204

204 -

205

205 -

206

206 -

207

207 -

208

208 -

209

209 -

210

210 -

211

211 -

212

212 -

213

213 -

214

214 -

215

215 -

216

216 -

217

217 -

218

218 -

219

219 -

220

220 -

221

221 -

222

222 -

223

223 -

224

224 -

225

225 -

226

226 -

227

227 -

228

228 -

229

229 -

230

230 -

231

231 -

232

232 -

233

233 -

234

234 -

235

235 -

236

236 -

237

237 -

238

238 -

239

239 -

240

240 -

241

241 -

242

242 -

243

243 -

244

244 -

245

245 -

246

246 -

247

247 -

248

248 -

249

249 -

250

250 -

251

251 -

252

252 -

253

253 -

254

254 -

255

255 -

256

256 -

257

257 -

258

258 -

259

259 -

260

260 -

261

261 -

262

262 -

263

263 -

264

264 -

265

265 -

266

266 -

267

267 -

268

268 -

269

269 -

270

270 -

271

271 -

272

272 -

273

273 -

274

274 -

275

275 -

276

276 -

277

277 -

278

278 -

279

279 -

280

280 -

281

281 -

282

282 -

283

283 -

284

284 -

285

285 -

286

286 -

287

287 -

288

288 -

289

289 -

290

290 -

291

291 -

292

292 -

293

293 -

294

294

|

|

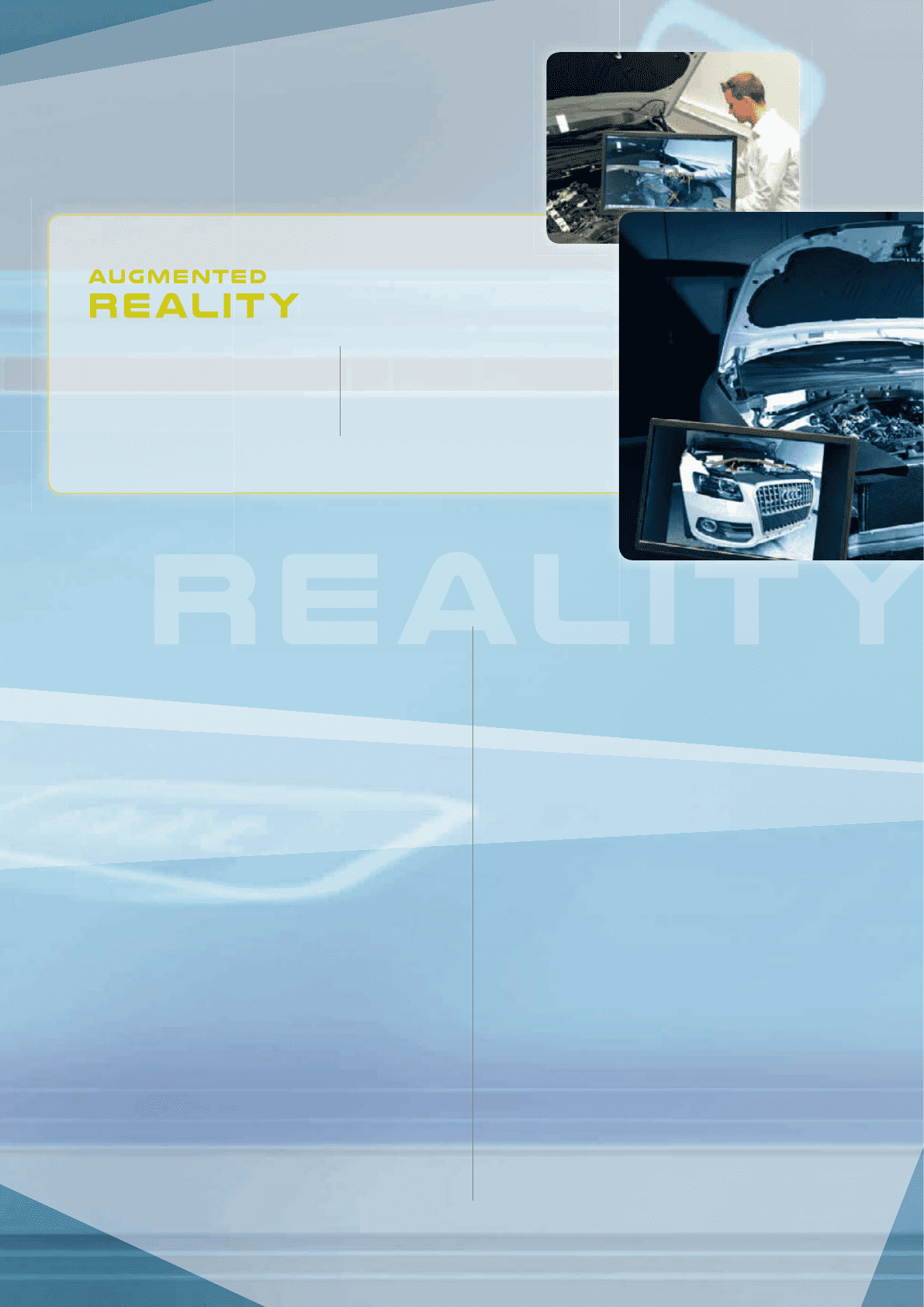

The design data and the actual vehicle are

compared for quality control purposes.

Optical overlay enables deviations to be

detected extremely quickly, modeled

in real time, analyzed and corrected, if

necessary. It is also possible to optically

link photo-realistic component data,

such as for a bumper, with the vehicle. For

the user, this merges the virtual with

the real world.

sheet is pulled over the tool. Actuators

then determine automatically how

tautly the sheet must be tensioned. Each

sheet can thus be pressed optimally

based on its individual characteristics.

“That is a new defi nition of precision,”

says Waltl proudly.

He learned precision from the ground

up. Waltl began his career over years

ago with an apprenticeship as a tool-

maker at Auto Union Ingolstadt. As an

apprentice back then, his tools of the

trade were still a slide rule and a draft-

ing table. He became interested early

on in the digitization of his fi eld of work.

“I was one of the fi rst programmers at

Audi Production. I fed punch cards into

computers the size of this entire room,”

he recalls. Waltl is among the pioneers

of the third industrial revolution.

Waltl and Neugebauer are now on their

way to the intelligent tool in the press

shop. They move from the biting cold of

this February morning into Hall N.

Hanging next to the entrance is the en-

gine hood of an Audi A – the fi rst pro-

duction part produced on the new press

line in . Precision is the press shop’s

aspiration. The body parts produced here

lay the foundation for Audi’s high quality

standards. The employees have signed

o on this concept. Their signatures on

the engine hood in the entrance area re-

mind them of that every day.

As many as , parts are produced

in Hall N each day. Like giant blue

stamps, the pressing machines press the

various molds into the steel or alumi-

num with a precision measured in hun-

dredths of a millimeter. A single hair

between the tool and the material or

just a bit too little oil can cause the part

to be rejected later during quality con-

trol. So the tool on this press line thinks

for itself. Sensors measure how the

Quality assurance with augmented reality : With the “Window to

the World” system, employees can today perform an extremely

precise variance analysis between the design data and a component,

in the engine compartment for example.

036

>>

>>

037WE CREATE PROGRESS

>>

>>

04