Panera Bread 2007 Annual Report Download - page 19

Download and view the complete annual report

Please find page 19 of the 2007 Panera Bread annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.Although many of our ingredients and products are prepared to our specifications, we believe that a majority of

the ingredients are based on generally available products that could be obtained from alternative sources if needed.

In addition, we frequently enter into annual and multi-year contracts for ingredients in order to decrease the risks

associated with supply and cost. Antibiotic free chicken, which is sold in Panera Company-owned and franchise-

operated bakery-cafes, is currently supplied by three different companies. However, there are few producers of

antibiotic free chicken, which may make it difficult, or more costly, for us to find alternative suppliers if necessary.

Generally, we believe that we have adequate sources of supply for our ingredients and products to support our

bakery operations or, if necessary, we could make menu adjustments to address material supply issues. However,

there are many factors which could cause shortages or interruptions in the supply of our ingredients and products

(i.e. wheat, produce, antibiotic free chicken, sweet goods and soup), including weather, unanticipated demand,

labor, production or distribution problems, quality issues and cost, some of which are beyond our control, and which

could have an adverse effect on our business and results of operations.

Our profitability depends in part on our ability to anticipate and react to changes in food and supply costs. In

the past, we have been able to recover inflationary cost and commodity price increases, including, among other

things, gasoline, proteins, dairy, wheat, tuna, and cream cheese costs, through increased menu prices. There have

been, and there may be in the future, delays in implementing such menu price increases, and competitive pressures

may limit our ability to recover such cost increases in their entirety. Historically, the effects of inflation on our net

income have not been materially adverse. However, the recent volatility experienced in certain commodity markets,

such as those for wheat, which have experienced a significant increase in prices, is expected to have an adverse

effect on us in fiscal 2008. The extent of the impact will depend on our ability and timing to increase food prices.

Disruptions or supply issues in our Panera fresh dough facilities could adversely affect our business and

results of operations.

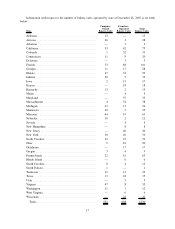

Panera operates 19 fresh dough facilities, which service all of Panera’s Company-owned and approximately

98 percent of Panera’s franchise-operated bakery-cafes. The fresh dough distribution system delivers fresh dough

products daily to the bakery-cafes through a leased fleet of temperature controlled vehicles. The optimal

distribution range is approximately 300 miles. However, when necessary, the distribution range may reach up

to 500 miles. As a result, any prolonged disruption in the operations of or distribution from any of the fresh dough

facilities, whether due to weather conditions, technical or labor difficulties, destruction or damage to the vehicle

fleet or facility or other reasons, could cause a shortage of fresh dough products at Panera’s bakery-cafes. Such a

shortage of fresh dough products could, depending on the extent and duration, have a material adverse effect on our

business and results of operations.

Additionally, increased costs and distribution issues related to fuel and utilities could also materially impact

our business and results of operations, including its efficiencies in distribution from Panera’s fresh dough facilities

to the Panera bakery-cafes.

Panera’s Franklin, Massachusetts fresh dough facility manufactures and supplies through its distributors all of

the cream cheese and approximately 98 percent of the tuna used in Panera’s Company-owned and franchise-

operated bakery-cafes. Although Panera believes it has adopted adequate quality assurance and other procedures to

ensure the production and distribution of quality products and ingredients, the possibility exists that it will be

subject to allegations regarding quality, health or other similar concerns that could have a negative impact on

Panera’s operations whether or not the allegations are valid or we are liable. Additionally, defending against such

claims or litigation can be very costly and the results uncertain.

We may not be successful in convincing our customers of the benefits of paying our prices for higher-

quality food.

Our success depends in large part on our ability to convince customers that food made with higher-quality

ingredients, including antibiotic-free chicken and our artisan breads, is worth the prices they will pay at our bakery-

cafes relative to prices offered by some of our competitors, particularly those in the quick-service segment. Our

inability to educate customers about the quality of our food or our customers rejection of our pricing approach could

require us to change our pricing, marketing or promotional strategies, which could materially and adversely affect

our results or the brand identity that we have tried to create.

9