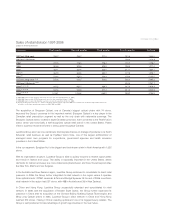

LensCrafters 2006 Annual Report Download - page 39

Download and view the complete annual report

Please find page 39 of the 2006 LensCrafters annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

|39 <

The Group’s strong growth in 2006 was supported by robust increase Italian and China’s production.

Having its origins in what has become the global center of eyewear manufacturing, northeast Italy,

Luxottica Group has produced prescription frames and sunglasses for over 40 years, controlling

every phase of the production process, from raw material procurement to manufacturing of the

finished frame. Its manufacturing process is the product of decades of careful honing, along a path

of constant research and development. In 2006, this involved rationalization, reorganization and

specialization of facilities in order to continue to achieve maximum efficiency and quality across the

entire manufacturing base.

In 2006, investments in manufacturing, from materials and machinery, to design and programming,

totaled Euro 70 million, reflecting the Group’s policy of building on achievements, rather than merely

showcasing them. Luxottica is committed to keeping its manufacturing platform the most efficient,

flexible and creative in an industry for which it already sets the benchmarks.

MANUFACTURING PLANTS AND PRODUCTION

Production is concentrated mainly in six plants in Italy,mostly in the northeast. Of these, the Sedico

plant, near Belluno, was expanded in 2006 and now covers approximately 30,000 square meters.

Given the growth in the business, the Group also decided to expand the Lauriano plant, which

specializes in glass and plastic sun lenses, by 11,000 square meters. The Group also has two

wholly-owned plants in China. One plant with 26,000 square meters started operations in 2006. The

Chinese plants handle the more labor-intensive lines of production, while the Italian facilities

concentrate on «Made in Italy» production, which has very high value-added qualities. Consumer

demand for such products is strong, driving the Group’s development of premium and luxury

products, both directly through its stores and indirectly through its wholesale customers. In 2006,

with this increased level of market demand, the Italian plants stepped up the production of luxury

brands and premium products in general.

On the materials front, 2006 saw an increase in the production of metal parts to meet demand for

metal detailing, even in plastic frames, while production with other materials, including injected

plastic and acetate, remained stable.

VERTICAL INTEGRATION

Over the decades, Luxottica Group has vertically integrated every phase of the production process

in order to achieve the efficiency goals of each type of product and service it offers. Control of the

various phases of production makes it possible to monitor the quality of products and processes,

introduce new operating methods and exploit synergies. It also enables production time and costs

to be kept under control and optimized. In addition to having efficient plants, the Group utilizes a

centralized system for monitoring inventory and orders. Daily analysis of this information, especially

from its retail business, provides data to support projections of demand, making it possible to plan

production and other necessary tasks in advance. The coordination of supply and demand reduces

potential problems in inventory and raw materials sourcing. This is a major competitive advantage.

Coordinating the production of the manufacturing plants with precise monitoring of the market

makes Luxottica Group efficient and puts it in the best possible position. The Group is able to

effectively meet its wholesale customers’ demands and adapt to changing trends in the market and

fashion in terms of both type and quantity of products.

MANUFACTURING