Tyson Foods 2009 Annual Report Download - page 13

Download and view the complete annual report

Please find page 13 of the 2009 Tyson Foods annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

13

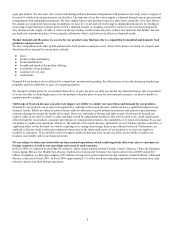

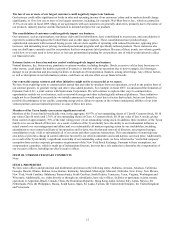

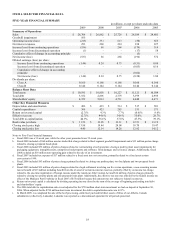

Number of Facilities

Owned

Leased

Total

Chicken Segment:

Processing plants

61

2

63

Rendering plants

14

-

14

Blending mills

2

-

2

Feed mills

42

-

42

Broiler hatcheries

62

7

69

Breeder houses

483

747

1,230

Broiler farm houses

864

812

1,676

Beef Segment Production Facilities

12

-

12

Pork Segment Production Facilities

9

-

9

Prepared Foods Segment Processing Plants

22

1

23

Distribution Centers

10

2

12

Cold Storage Facilities

65

10

75

Capacity(1)

Fiscal 2009

per week at

Average Capacity

October 3, 2009

Utilization

Chicken Processing Plants

48 million head

90%

Beef Production Facilities

170,000 head

82%

Pork Production Facilities

437,000 head

90%

Prepared Foods Processing Plants

45 million pounds

82%

(1) Capacity based on a five day week for Chicken and Prepared Foods, while Beef and Pork are based on a six day week.

Chicken: Chicken processing plants include various phases of slaughtering, dressing, cutting, packaging, deboning and

further-processing. We also have 17 pet food operations, which are part of the Chicken processing plants. The blending mills, feed

mills and broiler hatcheries have sufficient capacity to meet the needs of the chicken growout operations.

Beef: Beef plants include various phases of slaughtering live cattle and fabricating beef products. Some also treat and tan hides. The

Beef segment includes three case-ready operations that share facilities with the Pork segment. One of the beef facilities contains a

tallow refinery. Carcass facilities reduce live cattle to dressed carcass form. Processing facilities conduct fabricating operations to

produce boxed beef and allied products.

Pork: Pork plants include various phases of slaughtering live hogs and fabricating pork products and allied products. The Pork

segment includes three case-ready operations that share facilities with the Beef segment.

Prepared Foods: Prepared Foods plants process fresh and frozen chicken, beef, pork and other raw materials into pizza toppings,

branded and processed meats, appetizers, prepared meals, ethnic foods, soups, sauces, side dishes, pizza crusts, flour and corn tortilla

products and meat dishes.

We believe our present facilities are generally adequate and suitable for our current purposes; however, seasonal fluctuations in

inventories and production may occur as a reaction to market demands for certain products. We regularly engage in construction and

other capital improvement projects intended to expand capacity and improve the efficiency of our processing and support facilities.

ITEM 3. LEGAL PROCEEDINGS

Refer to the discussion of our certain legal proceedings pending against us under Part II, Item 8, Notes to Consolidated Financial

Statements, Note 22: “Contingencies,” which discussion is incorporated herein by reference. Listed below are certain additional legal

proceedings for which we are involved.

On October 23, 2001, a putative class action lawsuit styled R. Lynn Thompson, et al. vs. Tyson Foods, Inc. was filed in the District

Court for Mayes County, Oklahoma by three property owners on behalf of all owners of lakefront property on Grand Lake O’ the

Cherokees. Simmons Foods, Inc. and Peterson Farms, Inc. also are defendants. The plaintiffs allege the defendants’ operations

diminished the water quality in the lake thereby interfering with the plaintiffs’ use and enjoyment of their properties. The plaintiffs