Audi 2009 Annual Report Download - page 165

Download and view the complete annual report

Please find page 165 of the 2009 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

162

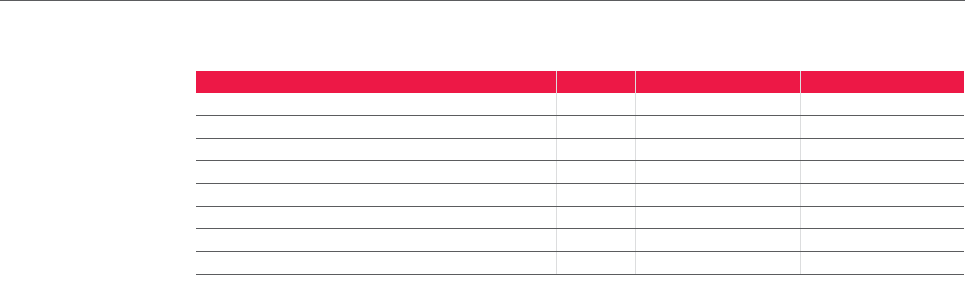

ENVIRONMENTAL STRUCTURAL DATA 1)

2009 2008

VOC emissions 2) t 1,750 1,928

Direct CO2 emissions 3) t 188,339 200,249

Volume of waste water m³ 1,708,808 1,852,538

Fresh water purchased m³ 2,702,821 2,905,370

Total volume of waste t51,896 63,520

of which recyclable waste t42,624 54,168

of which disposable waste t9,272 9,352

Metallic waste (scrap) t282,517 328,231

1) Ingolstadt, Neckarsulm, Brussels (excluding Volkswagen Polo), Győr and Sant’Agata Bolognese plants

2) VOC emissions (volatile organic compounds): This figure comprises emissions from the paint shops, shipment preservative

treatment for motor vehicles, test rigs and other facilities.

3) Direct CO2 emissions: This figure is made up of CO2 emissions generated by the use of fuel at the plant, and CO2 emissions

produced by the operation of test rigs.

In order to conserve energy and therefore reduce emissions, the potential for saving energy is

already considered during the planning phase. Permanent improvements in the efficiency of

manufacturing facilities and utilities are therefore also of considerable importance. Technical

solutions such as a modern combined heat, power and refrigeration plant at Ingolstadt as well

as heat recovery systems and the use of district heating have proved very successful for the Audi

Group. The signing of the new district heating contract for the Ingolstadt plant in fall 2009

means that the amount of waste heat from neighboring industrial enterprises being used is set

to continue rising.

Another example of how resources can be used more efficiently is the adoption of innovative

joining techniques in body manufacturing, such as spot welding, laser welding and bonding

techniques. Each individual technique is matched with specific joining processes in order to find

the most efficient solution for each process. Reductions in the consumption of operating mate-

rials and energy can thus be realized. The changeover from pneumatic welding tongs to a ver-

sion powered by electric motors has yielded a significant efficiency gain and improved the qual-

ity of weld points. For exactly the same level of use, energy consumption and therefore also CO2

emissions are cut by around 50 percent. Based on these positive findings, this technology will

now be adopted for all new projects in the Audi Group. Countless other individual measures such

as ventilation and lighting control on demand and optimized machine operation all contribute

towards ongoing, systematic reductions in energy use.

One pilot project on which AUDI AG is currently collaborating with the Technical University of

Munich involves recycling the raw material nickel from a pretreatment stage of the painting

process. The goal of this research project is to return the material to the manufacturing process,

thereby significantly reducing the amount of waste. Another pilot project within the Audi Group

has set out to investigate the biological treatment of rinsing effluent from the paint shop, again

with the aim of reducing the volume of waste. Other energy savings within the Audi Group are

being continually monitored from an economic and ecological viewpoint as part of potential

studies. In addition to the increased use of district heating, this includes the potential use of

pioneering renewable energy sources such as geothermal energy.

Environmental protection programs and public relations work

Another way in which the Audi Group exercises its environmental responsibility is through its

extensive involvement in numerous initiatives.

The Company for instance maintains a constant dialog with politicians, associations, govern-

ment agencies and journalists about its environmental philosophy, and is also deeply involved in

joint projects between government and industry. Its repeated participation in the Bavarian Envi-

ronmental Pact emphasizes how the Audi Group’s environmental commitment goes far beyond

the statutory requirements. It believes this is the only way to achieve the goal of enhanced inno-

vativeness harnessed to an environmentally acceptable and thus sustainable form of economic

growth. As a founding member, the Audi Group has for many years been contributing to forums

on a variety of topics such as the Integrated Product Policy (IPP) or the management systems.