Honeywell 2002 Annual Report Download - page 215

Download and view the complete annual report

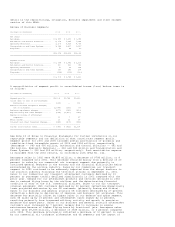

Please find page 215 of the 2002 Honeywell annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.contract cancellations and penalties, including lease terminations, negotiated

or subject to reasonable estimation. Also, $119 million of previously

established accruals, mainly for severance, were returned to income in 2001 due

principally to higher than expected voluntary employee attrition resulting in

reduced severance liabilities, principally in our Aerospace and Automation and

Control Solutions reportable segments.

In 2000, we recognized a repositioning charge of $338 million related to

announced global workforce reductions across all of our reportable segments,

costs to close a chip package manufacturing plant and related workforce

reductions. The charge also included asset impairments principally associated

with the completion of previously announced plant shutdowns in our Specialty

Materials reportable segment and the closure of an affiliate's chemical

manufacturing operations, and other environmental exit costs and period

expenses. The announced workforce reductions consisted of approximately 2,800

manufacturing and administrative positions, which are complete. Asset

impairments were principally related to manufacturing plant and equipment held

for sale and capable of being taken out of service and actively marketed in the

period of impairment. Also, $46 million of previously established accruals,

principally for severance, were returned to income in 2000 due to higher than

expected voluntary employee attrition resulting in reduced severance

liabilities, principally in our Automation and Control Solutions and Aerospace

reportable segments.

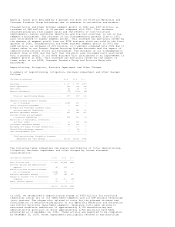

These repositioning actions are expected to generate incremental pretax savings

of approximately $400 million in 2003 compared with 2002 principally from

planned workforce reductions and facility consolidations. Cash expenditures for

severance and other exit costs necessary to execute these actions were $447,

$422 and $344 million in 2002, 2001 and 2000, respectively. Such expenditures

for severance and other exit costs have been funded principally through

operating cash flows. Cash expenditures for severance and other exit costs

necessary to execute the remaining 2002 actions will approximate $350 million in

2003 and will be funded principally through operating cash flows.

In 2002, we recognized business impairment charges of $877 million related to

businesses in our Specialty Materials and Automation and Control Solutions

segments, as well as our Friction Materials business. Based on current operating

losses and deteriorating economic conditions in certain chemical and

telecommunications end-markets, we performed impairment tests and recognized

impairment charges of $785 million in 2002 principally related to the write-down

of property, plant and equipment held for use in our Nylon System, Performance

Fibers and Metglas Specialty Materials businesses, as well as an Automation and

Control Solutions communication business. We also recognized impairment charges

of $92 million related principally to the write-down of property, plant and

equipment of our Friction Materials business, which is classified as assets held

for disposal in Other Current Assets (a plan of disposal of Friction Materials

was adopted in 2001; in January 2003, we entered into a letter of intent to sell

this business to Federal-Mogul Corp. --see Note 21 of Notes to Financial

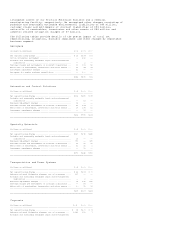

Statements for further discussion). In 2002, we recognized asbestos related

litigation charges of $1,548 million principally related to costs associated

with the potential resolution of asbestos claims of NARCO (see Note 21 of Notes

to Financial Statements for further discussion). In 2002, we also recognized

other charges consisting of customer claims and settlements of contract

liabilities of $152 million and write-offs of receivables, inventories and other

assets of $60 million. These other charges related mainly to our Advanced

Circuits business, bankruptcy of a customer in our Aerospace reportable segment,

and customer claims in our Aerospace and Automation and Control Solutions

reportable segments. Additionally, we recognized other charges consisting of

probable and reasonably estimable environmental liabilities of $30 million and

write-offs related to an other than temporary decline in the value of certain

cost investments of $15 million.

In 2001, we recognized other charges consisting of a settlement of the Litton

Systems, Inc. litigation for $440 million, probable and reasonably estimable

legal and environmental liabilities of $249 million (see Note 21 of Notes to

Financial Statements for further discussion), asbestos related litigation

charges of $159 million (see Note 21 of Notes to Financial Statements for

further discussion), customer claims and settlements of contract liabilities of

$310 million and write-offs of receivables, inventories and other assets of $335

million. Our Friction Materials business was designated as held for disposal,

and we recognized an impairment charge of $145 million related to the write-down

of property, plant and equipment, goodwill and other identifiable intangible

assets to their fair value less costs to sell. We recognized charges of $112

million related to an other than temporary decline in the value of an equity

investment and an equity investee's loss contract, and a $100 million charge for

write-off of investments, including inventory, related to a regional jet engine

contract cancellation. We also recognized $42 million of transaction expenses

related to the proposed merger with GE and redeemed our $200 million 5 3/4%

dealer remarketable securities due 2011, resulting in a loss of $6 million.

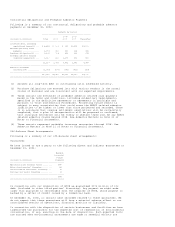

In 2000, we identified certain business units and manufacturing facilities as

non-core to our business strategy. As a result of this assessment, we

implemented cost reduction initiatives and conducted discussions with potential