Advance Auto Parts 2008 Annual Report Download - page 19

Download and view the complete annual report

Please find page 19 of the 2008 Advance Auto Parts annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report. 5

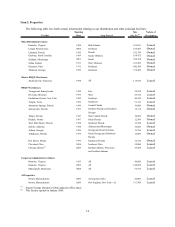

(1) Does not include stores that opened as relocations of previously existing stores within the same general market area

or substantial renovations of stores.

(2) Includes 2 and 7 stores not operating at December 30, 2006 and December 31, 2005, respectively, primarily due to

hurricane damage.

Store Technology. Our store-based information systems, which are designed to improve the efficiency of our

operations and enhance customer service, are comprised of a proprietary POS system and electronic parts catalog, or

EPC, system. Information maintained by our POS system is used to formulate pricing, marketing and

merchandising strategies and to replenish inventory accurately and rapidly. Our POS system is fully integrated with

our EPC system and enables our store Team Members to assist our customers in their parts selection and ordering

based on year, make, model and engine type of their vehicles. Our centrally-based EPC data management system

enables us to reduce the time needed to (i) exchange data with our vendors and (ii) catalog and deliver updated,

accurate parts information.

Our EPC system also contains enhanced search engines and user-friendly navigation tools that enhance our

Team Members’ ability to look up any needed parts as well as additional products the customer needs to complete

their automotive repair project. If a hard-to-find part or accessory is not available at one of our stores, the EPC

system can determine whether the part is carried and in-stock through our PDQ® system. Available parts and

accessories are then ordered electronically from another store, PDQ® or Master PDQ® with immediate confirmation

of price, availability and estimated delivery time.

We also support our store operations with additional proprietary systems. Our store-level inventory

management system provides real-time inventory tracking at the store level. With the store-level system, store Team

Members can check the quantity of on-hand inventory for any SKU, adjust stock levels for select items for store

specific events, automatically process returns and defective merchandise, designate SKUs for cycle counts and track

merchandise transfers. Our stores use radio frequency hand-held devices to help ensure the accuracy of our

inventory. Our standard operating procedure, or SOP, system is a web-based, electronic data management system

that provides our Team Members with instant and quick access to any of our standard operating procedures through

a comprehensive on-line search function. Additionally, we utilize a labor scheduling system known as management

planning and training, or MPT. All of these systems are tightly integrated and provide real-time, comprehensive

information to store personnel, resulting in improved customer service levels, Team Member productivity and in-

stock availability.

Store Support Center

Merchandising. Purchasing for virtually all of the merchandise for our stores is handled by our merchandise teams

located in our store support center in Roanoke, Virginia and in our regional office in Minneapolis, Minnesota. In

fiscal 2008, we purchased merchandise from over 400 vendors, with no single vendor accounting for more than 9%

of purchases. Our purchasing strategy involves negotiating agreements with certain vendors to purchase

merchandise over a specified period of time along with other terms, including pricing, payment terms and volume.

Our merchandising team is skilled in sourcing high quality products globally and maintaining consistent

inventory levels. The merchandising team has developed strong vendor relationships in the industry and, in a

collaborative effort with our vendor partners, utilizes a category management process. We believe this process,

which develops a customer-focused business plan for each merchandise category, has been highly effective and is

critical to improving comparable store sales, gross margin and inventory turns.

Our merchandising strategy is to carry a broad selection of high quality brand name automotive parts and

accessories such as Bosch®, Castrol®, Sylvania®, Prestone®, Monroe®, Wagner®, Purolator®, Dayco®, Trico® and

Federal-Mogul Moog®, or Moog®, which generates DIY customer traffic and also appeals to Commercial customers.

In addition to these branded products, we stock a wide selection of high quality proprietary products that appeal to

value conscious customers. These lines of merchandise include everything from chemical and wash-and-wax

products to tools, batteries, parts and interior automotive accessories under various private label names.