Entergy 2002 Annual Report Download - page 17

Download and view the complete annual report

Please find page 17 of the 2002 Entergy annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

ENTERGY CORPORATION AND SUBSIDIARIES 2002 15

y achieving success in our nuclear strategy,

we’re proving the value of nuclear power

through economical, safe, and secure operations.

We’re driving growth through increased

productivity and generating capacity.

Strong execution of a successful strategy

In 2002, our nuclear business achieved high

capacity factors and record-breaking refueling

outages to create value from our growing fleet

of nuclear plants.

Entergy Nuclear continued to grow its capacity

to generate both power and income. Vermont

Yankee – Entergy’s tenth nuclear unit and fifth in

the Northeast – was acquired in July 2002.

In 2002, Entergy’s nuclear plants performed

at an average capacity factor of 96 percent,

despite seven refueling outages. The capacity

factor measures the percentage of potential

generation actually produced by a plant.

Capacity factors have increased more quickly

than expected at Northeast plants acquired in

the past four years. The increase in capacity

factors at newly acquired plants, compared with

the average for the three years before each

plant was acquired, produces an additional

7 million megawatt-hours a year.

Entergy has reduced average costs for

scheduled refueling outages. In 2002, we

completed seven refueling outages, most in near-

record time and without lost-time accidents.

A refueling outage at Arkansas Nuclear One

Unit 2 set a world record for units designed by

Combustion Engineering. A 21-day outage at

Vermont Yankee improved on the previous

record by more than two days, and a 32-day

outage at Indian Point 2 was less than half the

duration of the previous record.

We’re managing market risk. Each time

Entergy has acquired a nuclear plant, the seller

has entered into a power purchase agreement

for the initial years we own the plant. These

PPAs create a stable revenue stream from

creditworthy counterparties. So our nuclear

plants have a risk profile distinctly different

from that of merchant power plants.

A key goal, as existing agreements roll off, is

to close new PPAs at attractive prices or otherwise

hedge plant output. To date, we have sold forward

under contracts 100 percent of output for 2003,

92 percent for 2004, and 25 percent for 2005.

A commitment to safety and security

Entergy is successfully meeting the challenges of

safety and security at our nuclear plants, while

continuing to reduce overall costs.

We conducted thorough inspections to

confirm the safety of Entergy’s pressurized

water reactor units, after corrosion at another

company’s nuclear plant raised questions about

PWRs. We found no problems at three plants,

and we repaired minor problems during a

refueling outage at ANO Unit 1.

We’ve ordered a new reactor vessel head for

ANO Unit 1, to be installed during a scheduled

outage in 2005. The cost to replace the reactor

vessel head is approximately $20 million. By

having a replacement ready, we’ll avoid the risk

of a much more costly extended plant shutdown.

We’ve improved safe performance at Indian

Point 2. In September, the Nuclear Regulatory

Commission lifted its “red” finding on Indian

Point 2. The red designation was placed on the

plant in February 2000, under previous ownership.

BB

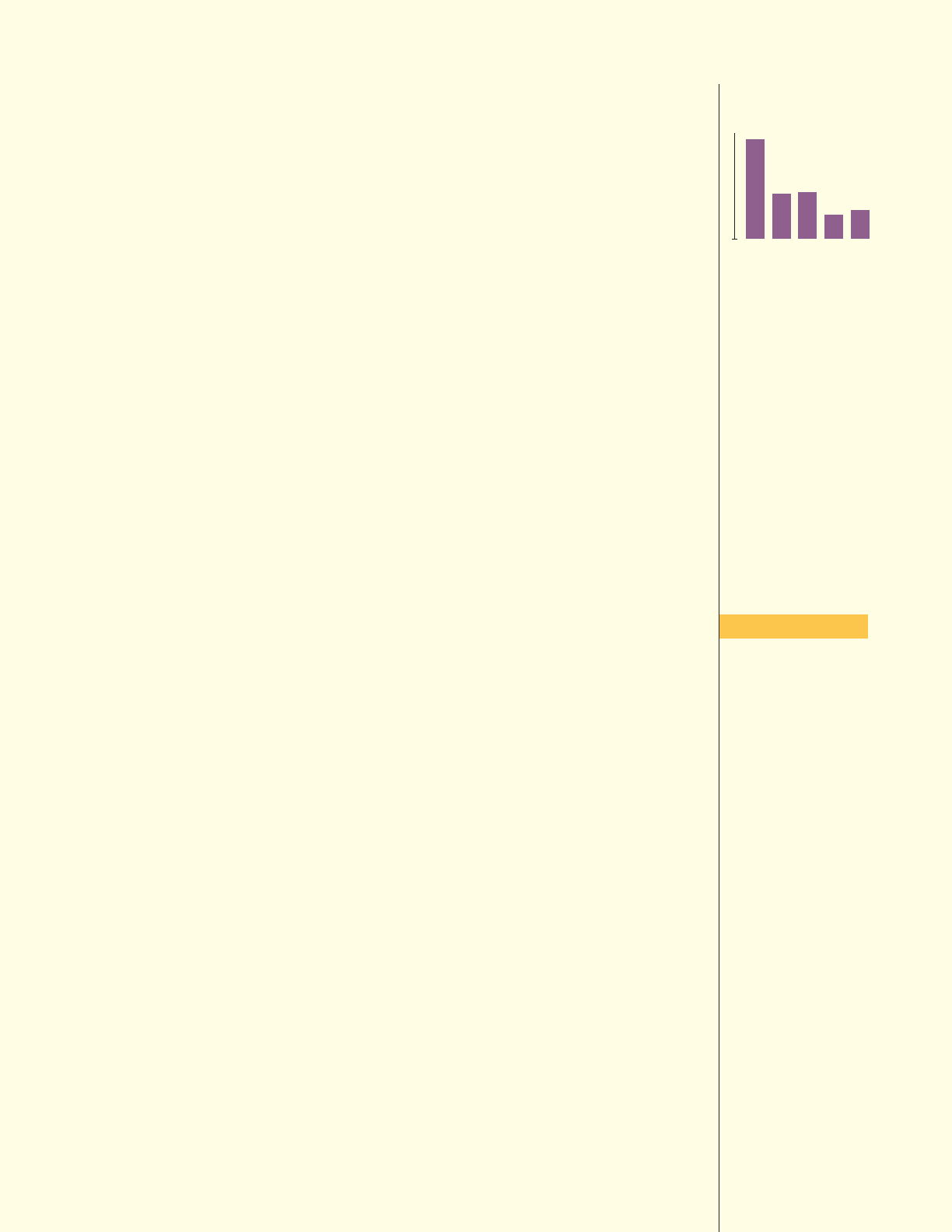

Employee

Lost-Time Accidents

Entergy is keeping the

focus on employee safety.

Since 1998, we’ve

reduced the number of

lost-time accidents by over

50 percent. We also

achieved significant

reductions in less severe

restricted duty accidents

and cases requiring

medical attention in 2002.

RECOGNITION

Generating Plant Safety

In 2002, Sterlington Plant

earned Voluntary

Protection Program Star

status from the U.S.

Occupational Safety and

Health Administration, for

protecting employees’

health and safety. Eight

Entergy plants are among

approximately 30 U.S.

electric and gas facilities

with the VPP Star rating.

Entergy sites include the

first electric generating

plants (Little Gypsy and

Waterford 1 & 2), the

first nuclear plant

(Arkansas Nuclear One),

and the first nuclear fleet

(Entergy Nuclear South)

to earn VPP Star status.

98 99 00 01 02

76

45 46

33 36

Prior year numbers have been

updated to reflect OSHA Guidelines

Another area of focus for the utility is

productivity improvements. For example, fossil

plant operations employees completed more

than 40 “Six Sigma” projects in 2002, achieving

over $6.4 million in realized fuel savings and

$542,000 in reductions in direct capital and

operating and maintenance expenses.

In addition, we’re pursuing economic

development to maintain and grow our

commercial and industrial customer base.

NUCLEAR: PROVING THE VALUE