Pentax 2009 Annual Report Download - page 15

Download and view the complete annual report

Please find page 15 of the 2009 Pentax annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Future Strategies

One of the trends in the photomask market is the continued decline

in overall demand resulting from customers reducing the types of

products used. In turn, this trend arises from a movement towards

concentrating manufacturing in fabs (chip manufacturing specialists)

and corporate reorganizations in the semiconductor industry. In

recognition of these trends, Hoya is focusing more than ever before

on maintaining close relationships with customers. The Company

sees its highest priority issue as providing customers with optimum

solutions as their partner for advanced technology development.

Going forward, Hoya intends to stay ahead of competitors with

the latest next-generation lithography equipment, introduced in

the fiscal year under review, working to further strengthen its com-

petitiveness. In addition, the Company is utilizing correction tech-

nology for writing processes and simulation technology to

duplicate semiconductor exposure processes to provide its own

original high-value-added solutions.

PHOTOMASKS FOR LCD PANEL PRODUCTION

Fiscal 2009 Business Overview and Results

Hoya manufactures LCD photomasks, which are the master plates

used in the manufacture of LCD panels for flat-panel televisions and

computer monitors.

Hoya has leveraged several advantages in winning top share of

the global market for LCD photomasks. It supplies high-value-added

products that utilize technology accumulated in the development of

photomasks for semiconductors. It also has a tripolar production

system featuring hubs in Japan, Taiwan, and South Korea that

enables rapid response to customer needs.

In the fiscal year under review, LCD panel manufacturers contin-

ued to actively increase capital investment in anticipation of a surge

in demand related to the Beijing Olympics. Accordingly, Hoya fared

well in the first half. However, in the second half, lower demand than

expected from the Beijing Olympics and lagging consumption

because of the economic downturn following the Lehman Brothers

shock resulted in LCD panel inventory levels being substantially

higher than demand. Consequently, the Company experienced a

sharp decline in demand beginning in the third quarter along with

continued strong downward pressure on prices. Overall sales fell

compared with the previous fiscal year.

Future Strategies

In the past, LCD panel manufacturers have mainly relied on increas-

ing the size of the glass used as a substrate to improve their pro-

ductivity. Today the new challenge is to pursue further gains in

productivity with an eye to achieving cost reductions within the

manufacturing process. Within that trend, Hoya’s multi-tone mask*2

is a breakthrough product that promises to lower manufacturing

costs through its significant contributions to reducing the number

of processes in LCD manufacturers’ production lines and increasing

yields. In the fiscal year under review, the Company implemented

improvements to the defect rates and degree of precision of multi-

tone masks, focusing on differentiating its products in the market.

Hoya also began such activities as utilizing inspection technology to

raise the quality guarantee level for its LCD photomasks. Moving

forward, the Company intends to take the initiative in the market by

developing and proposing technologies that will be valued by LCD

panel manufacturers seeking to improve productivity.

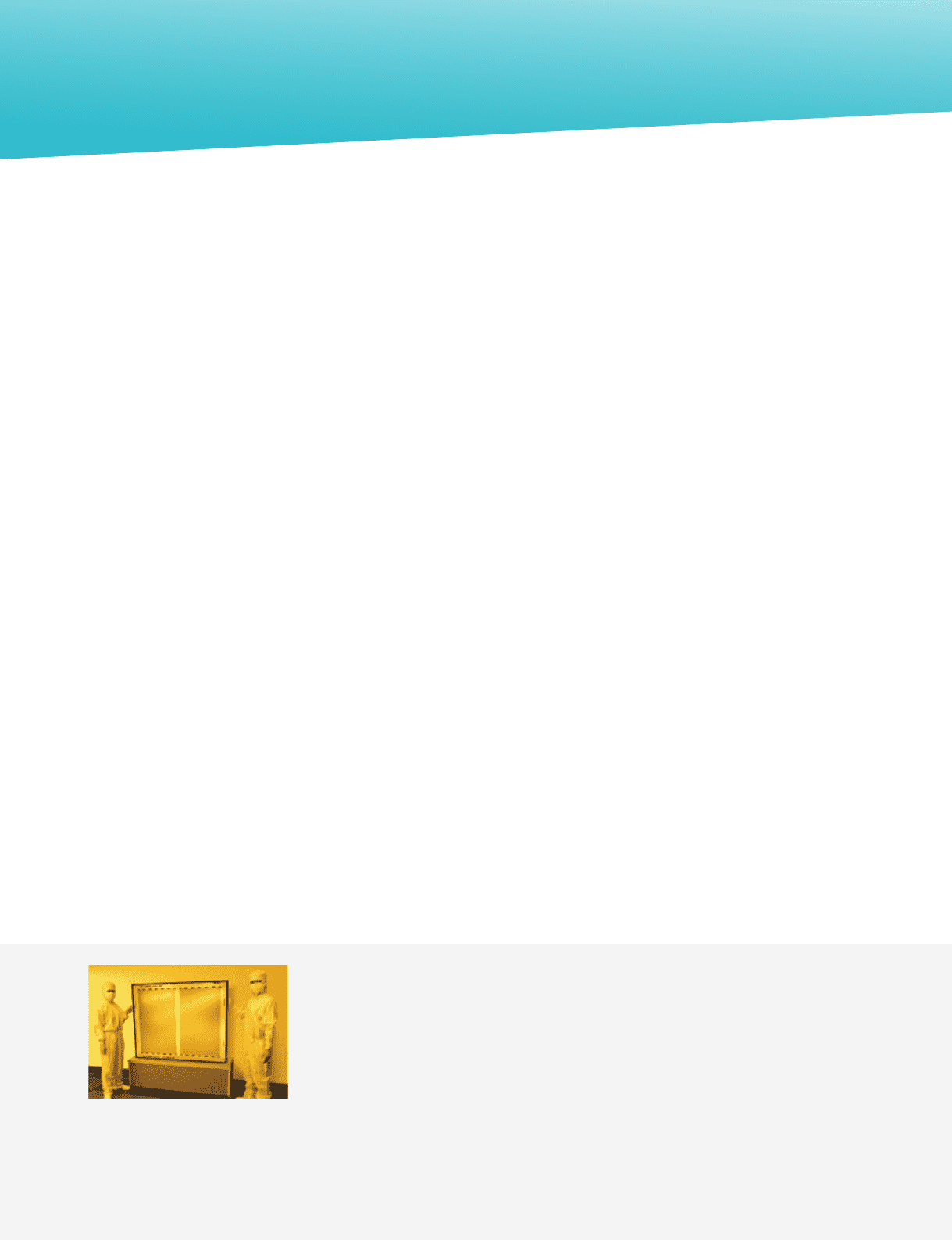

8th generation photomasks

(1,220mm X 1,400mm)

An 8th generation glass sub-

strate can yield screens for six

50-inch LCD TV panels.

*1 Phase shift mask blanks

These mask blanks have a semi-transparent film coating

between the glass substrate and a metallic film layer that

enables the printing of smaller circuits. High-value-added

products that increase the functionality of devices and

enables greater miniaturization, phase shift mask blanks are

contributing to the greater profitability of the business.

*2 Multi-tone masks

Multi-tone masks can reduce the number of processes used

in LCD panel production from five to four. Consequently,

they contribute to reducing the manufacturing costs of LCD

panel manufacturers and increasing their productivity.

13

HOYA Annual Report 2009