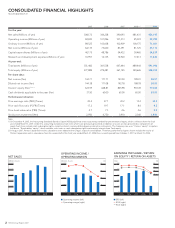

Pentax 2009 Annual Report Download - page 14

Download and view the complete annual report

Please find page 14 of the 2009 Pentax annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

MASK BLANKS FOR

SEMICONDUCTOR PRODUCTION

Fiscal 2009 Business Overview and Results

Hoya produces photomasks, which are the master plates used to

transfer the semiconductor circuit patterns to silicon wafers, and the

mask blanks that form the substrate for the photomasks. The Com-

pany supplies these products to semiconductor manufacturers in

Japan and overseas and boasts an overwhelming share of the global

market for mask blanks, particularly high precision mask blanks.

In the fiscal year under review, business in the semiconductor

industry was robust during the first half. Against the backdrop of an

economic slowdown that began in the second quarter, however, the

second half witnessed large-scale reductions in production and

curtailment of product development budgets and capital invest-

ments in the industry. Amid these market movements, sales of mask

blanks fell in the second half because of the sharp drop in demand

and pressure on prices, producing an overall decline in sales year

on year. Even high precision products, such as the phase-shift mask

blanks*1 that had driven earnings growth in the past, faced a dif-

ficult business environment.

Future Strategies

Despite steady progress in cutting edge semiconductor develop-

ment, mass production of the devices utilizing these chips have

slowed the pace at which the industry shifts to the next generation

of semiconductors. Consequently, a clear gap has opened up

between technology progress and market needs. Furthermore, with

the steadily worsening business climate surrounding the semicon-

ductor industry, individual companies are limiting their investments

in chip development and focusing their efforts on building cost-

conscious, efficient production systems.

In recognition of these market needs, Hoya’s strategy has been

seeking other ways of increasing the degree of satisfaction of its

customers besides its miniaturization-oriented product develop-

ment by providing customers with added value. Its efforts have

included material development to further heighten the durability

of its products.

PHOTOMASKS FOR

SEMICONDUCTOR PRODUCTION

Fiscal 2009 Business Overview and Results

A photomask is a mask blank onto which a pattern has been drawn

with an electron beam or laser writing device. Hoya has developed

a highly competitive business model in the photomask market,

strongly developing the business by specializing in cutting edge

technology development and by taking advantage of in-house

mask blank operations to differentiate itself from competitors in

terms of its material processes.

In the fiscal year under review, Hoya put effort into providing

high-quality, cutting edge photomasks. Although there were some

successes with the introduction of new types of photoresist films

and mask blank materials compatible with cutting edge manufac-

turing processes for semiconductors, such as immersion lithogra-

phy, adverse business conditions such as stagnation in the

semiconductor market, a slump in demand for photomasks and

downward pressure on prices resulted in lower sales year on year.

Electro-Optics Division

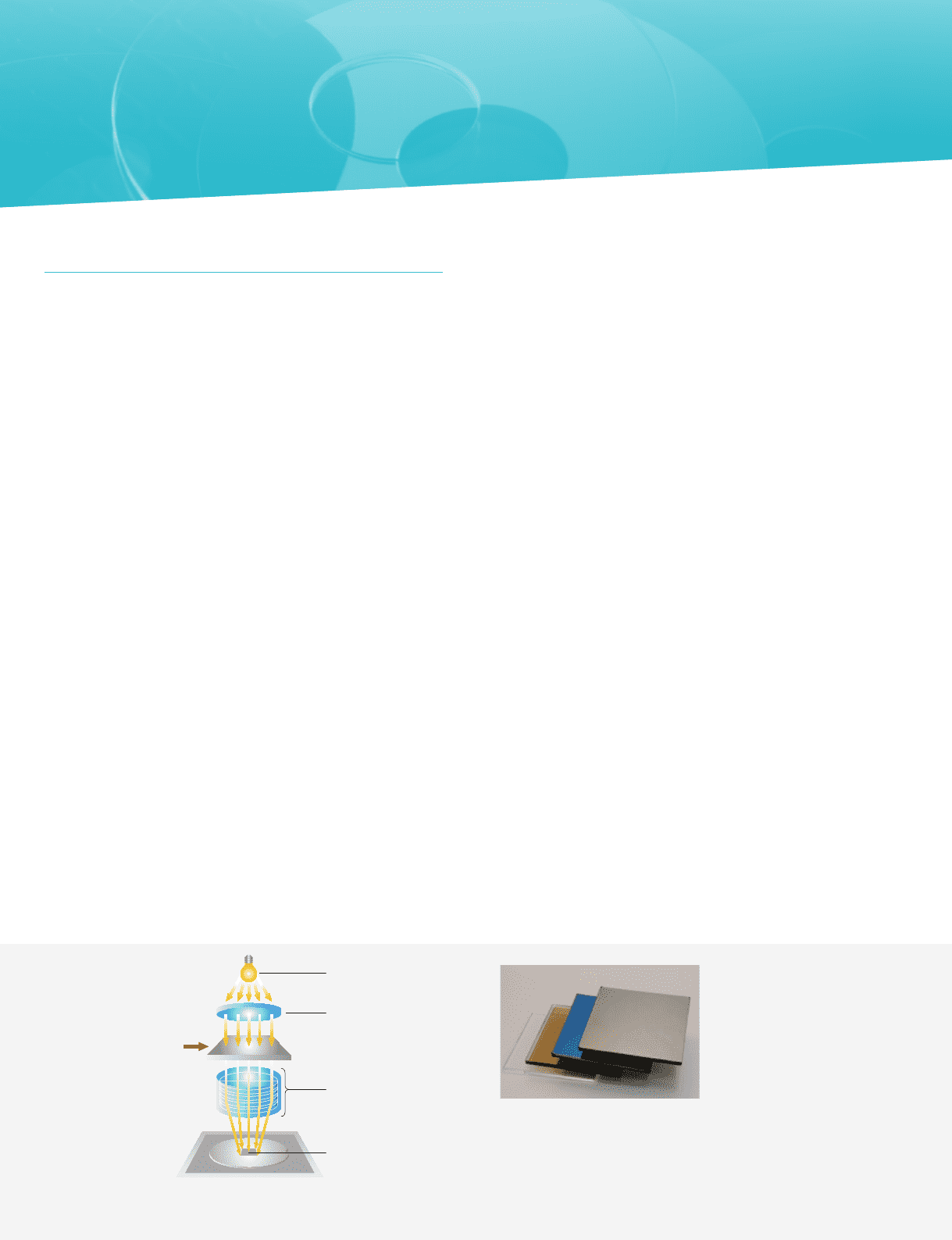

Illustration of circuit pattern

transfer using a lithographic

exposure process during semi-

conductor production

Mask blanks

From the left: a glass sub-

strate, a phase-shift halftone

mask blank, a homogenous

metallic film coated layer and

a completed blank with photo-

resist coating.

Light source

Condenser lens

Reduced projection

exposure lens unit

Photomask

Wafer

(semiconductor chip)

Hoya contributes to an abundant and prosperous future through advanced technology supporting progress in the functions

and value-added content of digital products, such as personal computers and large flat panel LCD televisions.

INFORMATION TECHNOLOGY

12 HOYA Annual Report 2009