Pentax 2008 Annual Report Download - page 16

Download and view the complete annual report

Please find page 16 of the 2008 Pentax annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Offering new value in harsh market conditions

In the fiscal year under review, panel manufacturers slowed the

pace of investments in facilities, and the thriving panel market led

to a greater emphasis on mass production of existing models than

on new product development, which reduced the number of new

orders for photomasks and softened overall demand in the

market. Coupled with plunging prices for certain products, the

Company faced a year fraught with adversity.

Under such circumstances, Hoya worked to further cut costs

and implemented new technologies to provide products that aid

customers in streamlining and reducing costs in their production

processes. For example, the Company is working to expand sales

of its multi-tone mask, which can contribute to productivity

through a 15% to 20% physical reduction in the panel

manufacturing process. We have also applied high-level

techniques used in photomasks for semiconductors, which we

have been involved in for many years, to commence technical

services that simulate customers’ production processes with the

aim of improving the process environment. As a result, our

customers have reevaluated our advanced technical abilities and

service quality, which we believe has succeeded in enhancing

customer trust in Hoya’s frontline technology capabilities.

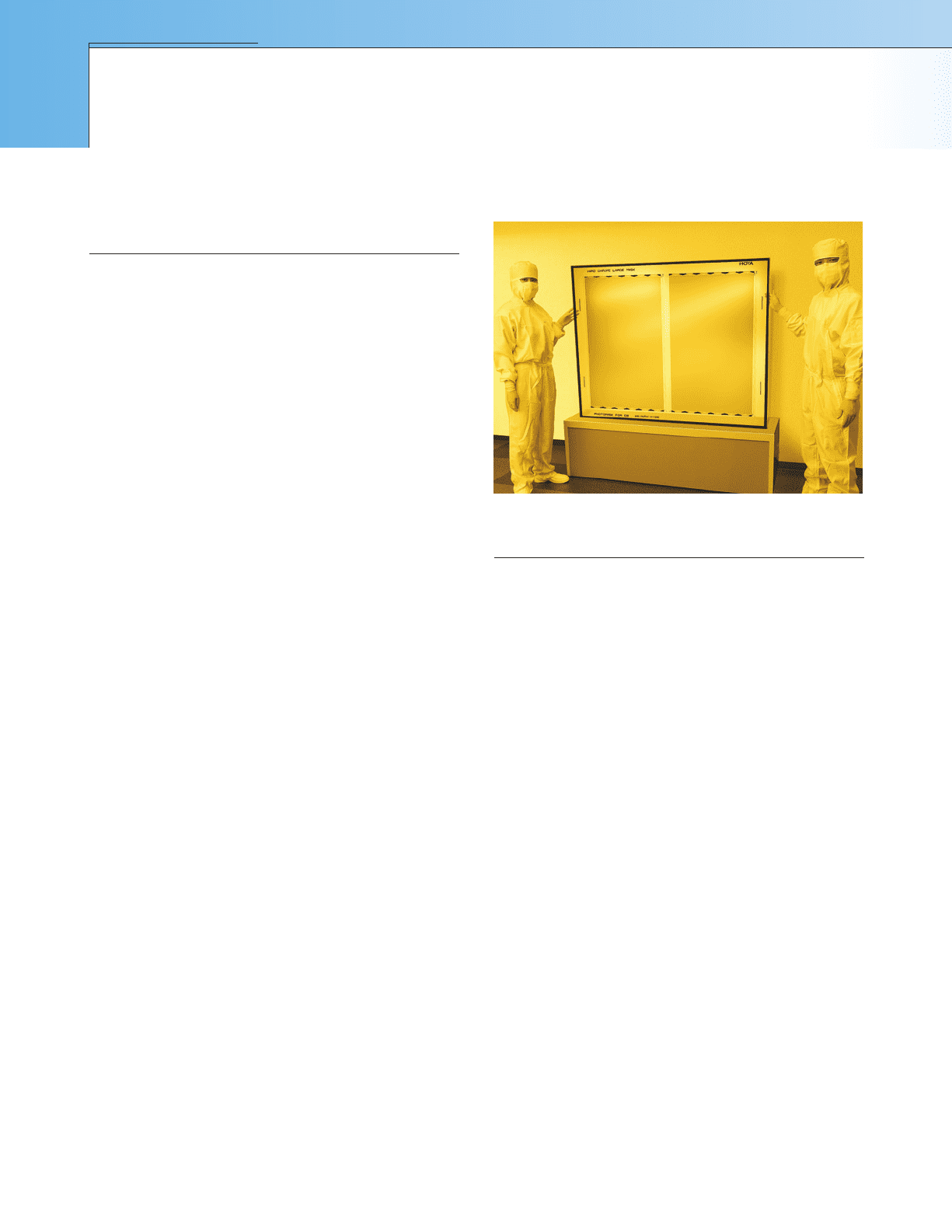

From autumn 2006, Hoya commenced in-house production of

glass substrates (mask blanks) for LCD photomasks and

reorganized its production system to incorporate all manufacturing

stages from substrate to photomask. These changes have

bolstered cost competitiveness by raising photomask quality and

ensuring substrate supply. In addition, the tripolar production

system the Company has been promoting since 2005, with hubs

in Japan, Taiwan and South Korea, enables rapid response to

customers in each region. There has been a growing tendency in

recent years for panel manufacturers to keep a cautious eye on

final demand when placing orders for photomasks. Hoya and

other photomask producers are therefore being asked to deliver

quality customized products in short time frames. In combination

with in-house production of mask blanks, this tripolar system

allows for agile response to such customer needs.

We are extending our market lead through

technological innovation and detailed accommodation

of customer needs

As lower prices transform LCD televisions into consumer goods

readily purchasable by the general public in a process known as

“commoditization,” the global market is projected to continue

expanding in the year ahead, boosted by the Olympic Games and

the spread of digital broadcasting networks. In the year ahead, we

expect panel manufacturers to ramp up capital investment and

establish new production lines in response to such demand, and

the supply and demand situation in the photomask market is

predicted to turn favorable.

Hoya will capitalize on these opportunities to elevate its

presence in the market by continuing its technological innovation

and responding carefully to the diverse needs of each customer.

In the brief space of 10 years, the LCD panel market has rushed

through a growth process that took the semiconductor market 30

years to complete, and there is still considered to be substantial

room for refinement of production techniques. The Company

aims to offer ground-breaking products to support the sustained

growth of LCD panels by applying the technical capabilities we

have accumulated in semiconductor photomasks to LCD

photomasks.

Information Technology

Significant Actions Taken and Results Achieved in

the Fiscal Year under Review

Policies and Forecasts for the Year Ahead

Highlights

Pursuing excellence in quality, delivery times and

costs to nimbly respond to customer needs

Large-sized LCD photomask (1,220 mm × 1,400 mm) used for eighth-generation LCD panels

14