BMW 2003 Annual Report Download - page 23

Download and view the complete annual report

Please find page 23 of the 2003 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

001 BMW Group in figures

004 Report of the Supervisory Board

008 Supervisory Board

011 Board of Management

012 Group Management Report

12 A Review of the Financial Year

29 Outlook

30 Financial Analysis

44 Risk Management

047 BMW Stock

050 Corporate Governance

054 Group Financial Statements

118 BMW AG Principal Subsidiaries

120 BMW Group10-year Comparison

122 BMW Group Locations

124 Glossary, Index

22

Construction work for phase VII of the extension

at the BMW Steyr plant commenced in April 2002.

One of the main items of investment here is a new

37,000 m2production hall, where core components

for engines such as crank cases and cylinder heads

will be manufactured using state-of-the-art pro-

duction techniques. This is the most extensive of

the various construction phases, which will be com-

pleted in 2004, and will increase the size of the plant,

in square metre terms, by a third.

At the end of September, production of the

updated BMW X5 was commenced at the BMW

Spartanburg plant. In 2003, the BMW Group also

tapped a hitherto unused source of energy for use

in Spartanburg. Up to 25% of the plant’s energy

requirements are now covered by methane gas,

supplied from a waste disposal site situated some

15 km away from the plant.

The body in white area was expanded at the

BMW plant in Rosslyn, South Africa in preparation

for new models. In addition, the flow of materials

throughout the plant was optimised in terms of

quality, speed and safety.

Series production of the MINI One D began at

the Oxford plant in March 2003. The overall high

demand for MINI cars resulted in a further increase

in production volumes. With the aid of flexible work-

time arrangements, more than 174,300 units were

manufactured.

Certified environmental management systems

have been in place at all of the BMW Group’s pro-

duction sites around the world since 1999. Working

together with centralised production divisions, these

systems have been further developed in the period

up to 2003 into an integrated environmental manage-

ment

system. The move to a certification matrix

covering both environmental care and quality issues

has therefore now been completed. Internal audits

and other measures are now managed centrally and

reported as part of the same reporting system.

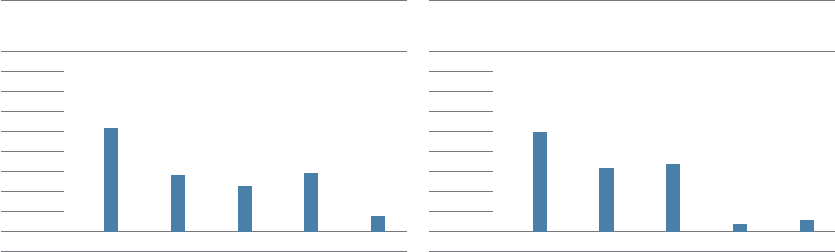

The progress made in the area of production-

related environmental care is reflected by the quan-

tity of energy and water consumed and emissions of

CO2and volatile organic compounds: almost all of

the relevant key figures significantly improved in 2003,

and represent benchmarks for the whole industry.

Capital expenditure increased again

The BMW Group is laying the foundation for contin-

ued expansion in the years ahead with substantial

levels of capital expenditure. In 2003, the Group

invested euro 3,249 million in intangible assets and

property, plant and equipment. Together with devel-

opment costs of euro 996 million which are required

to be recognised as assets in accordance with

IAS 38, total additions to intangible assets and prop-

erty, plant and equipment amounted to euro 4,245

million. This represents an increase of 5.0 %.

Volatile organic compounds (VOC) per unit produced

(kg/unit)

4.50

4.25

4.00

3.75

3.50

3.25

3.00

2.75

99 00 01

3.80

3.21 3.07

02*03

3.23

2.70

Process effluent per manufactured car

(m3/unit)

1.30

1.25

1.20

1.15

1.10

1.05

1.00

0.95

99 00 01

1.15

1.06 1.07

02

0.92

03

0.93

*increase in 2002 due to the new computation basis in accordance with the Volatile

Organic Compounds Regulation (31st Federal Regulation on Gas Emissions)