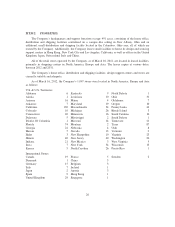

Abercrombie & Fitch 2011 Annual Report Download - page 21

Download and view the complete annual report

Please find page 21 of the 2011 Abercrombie & Fitch annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

We do not own or operate any manufacturing facilities and, therefore, depend upon independent third

parties for the manufacture of all our merchandise.

We do not own or operate any manufacturing facilities. As a result, the continued success of our

operations is tied to our timely receipt of quality merchandise from third-party manufacturers. Our products

are manufactured to our specifications primarily by foreign manufacturers. We cannot control all of the

various factors, which include inclement weather, natural disasters, political and financial instability,

strikes, health concerns regarding infectious diseases in countries in which our merchandise is produced,

and acts of terrorism, that might affect a manufacturer’s ability to ship orders of our merchandise in a

timely manner or to meet our quality standards. A manufacturer’s inability to ship orders in a timely

manner or meet our quality standards could cause delays in responding to consumer demands and

negatively affect consumer confidence in the quality and value of our brands or negatively impact our

competitive position, any of which could have a material adverse effect on our financial condition and

results of operations. We are also susceptible to increases in sourcing costs from our manufacturers which

we may not be able to pass on to our customers and could adversely affect our financial condition or results

of operations.

Additionally, while we utilize third-party compliance auditors to visit and monitor the operations of

our manufacturers, we do not have control of the independent manufacturers or their labor practices. As a

result, the risk remains that one or more of our manufacturers will not adhere to our global compliance

standards and violate labor laws or other laws, including consumer and product safety laws.

Non-governmental organizations might attempt to create an unfavorable impression of our sourcing

practices or the practices of some of our vendors or manufacturers that could harm our image. If either of

these events occur, we could lose customer goodwill and favorable brand recognition.

Our reliance on two distribution centers domestically and two third-party distribution centers

internationally makes us susceptible to disruptions or adverse conditions affecting our distribution

centers.

Our two distribution centers located in New Albany, Ohio, manage the receipt, storage, sorting,

packing and distribution of merchandise to our North American stores and to our North American and

Asian direct-to-consumer customers. We also use a third-party distribution center in the Netherlands to

manage the receipt, storage, sorting, packing and distribution of merchandise delivered to our stores and

direct-to-consumer customers in Europe and a third-party distribution center in Hong Kong to manage

receipt, storage, sorting, packing and distribution of merchandise delivered to our stores in Asia. As a

result, our operations are susceptible to local and regional factors, such as system failures, accidents,

economic and weather conditions, natural disasters, demographic and population changes, as well as other

unforeseen events and circumstances. If our distribution operations were disrupted, our ability to replace

inventory in our stores and process direct-to-consumer orders could be interrupted and sales could be

negatively impacted.

We are in the process of consolidating our two distribution centers in New Albany into one

distribution center, with an expected completion date at the end of Fiscal 2012. This consolidation requires

management’s focus and attention, as well as significant capital investments. We believe this consolidation

will result in improved operational efficiencies and that one distribution center in New Albany is adequate.

However, if we are unable to operate effectively with one distribution center, our distribution operations

could be disrupted. Furthermore, consolidation into one distribution center increases our susceptibility to

risks associated with system failures, accidents, weather conditions, natural disasters, and other unforeseen

18