Nissan 2004 Annual Report Download - page 31

Download and view the complete annual report

Please find page 31 of the 2004 Nissan annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

NISSAN HAS DRAMATICALLY REDUCED ITS PURCHASING COSTS—ITS

LARGEST COST AREA—THROUGHOUT NISSAN 180. LEVERAGING THE

STRENGTHS OF THE NISSAN 3-3-3 PROGRAM AND THE RENAULT-NISSAN

PURCHASING ORGANIZATION (RNPO), COSTS HAVE BEEN REDUCED AHEAD

OF SCHEDULE, AND CONTINUE TO BE CUT.

World-Class Cost Performance

PURCHASING

Nissan Annual Report 2003 29

The second year of NISSAN 180 saw the

continuation of a trend necessary for

Nissan’s profitability—the ongoing cuts in

purchasing costs.

Purchasing represents the highest

source of costs for any automaker, so

Nissan saw that improvements would be

a key part of returning the company to

sustainable, profitable growth. NISSAN

180 has a commitment of a 15-percent

reduction in costs, building on the 20

percent reduction already achieved during

the Nissan Revival Plan. In 2003, cost cuts

continued, moving on schedule toward the

NISSAN 180 commitment.

The first tool to realize this cost

reduction is the Nissan 3-3-3 program.

Three sets of “3s”: a teamwork of supplies,

purchasing and engineering; the three

regions of Japan/Asia, the Americas,

Europe/Middle East/Africa; and a three-

year period. By focusing on these

important groupings, Nissan has been able

not only to cut costs, but to increase

efficiency and realize higher cost

performance while actually improving

quality. In all, Nissan 3-3-3 has been a

win-win situation for both Nissan and its

suppliers, both of whom benefit from

expanded business volumes.

Joint Purchasing Moves Ahead

When two major global automobile

manufacturers joined in the Renault-Nissan

Alliance, they brought together

a remarkable level of purchasing power.

To leverage this strength, the Renault-

Nissan Purchasing Organization (RNPO),

a joint purchasing company, was

established in 2001. Since its founding,

the RNPO has continued to build the

highest purchasing competitiveness in

quality, cost and delivery, while managing

supplier relations on a global basis.

In fiscal year 2003, the share of

purchasing for both companies handled by

RNPO was boosted dramatically, rising

from 43 percent of total global purchasing

to fully 70 percent. This represents an

increase in total value from US$21.5 billion

in 2002 to some $33 billion in 2003.

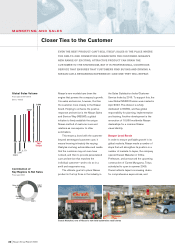

100

80

Target

’99 ’00 ’01 ’02 ’03 ’04 (FY)

NISSAN 180

-15%

NRP

-20%

Nissan 3-3-3 activity meeting

Reduced Purchasing Costs

Purchasing cost reduction (percent)