JetBlue Airlines 2010 Annual Report Download - page 17

Download and view the complete annual report

Please find page 17 of the 2010 JetBlue Airlines annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Maintenance

We have an FAA-approved maintenance program which is administered by our technical operations

department. Consistent with our core value of safety, we use qualified maintenance personnel, ensure they

have comprehensive training and maintain our aircraft and associated maintenance records in accordance with,

and often exceeding, FAA regulations.

The work performed on our fleet is divided into four general categories of maintenance: aircraft line,

aircraft heavy, component and power plant. The bulk of line maintenance requirements are handled by JetBlue

technicians and inspectors and consist of daily checks, overnight and weekly checks, A checks, diagnostics

and routine repairs. All other maintenance activity is sub-contracted to qualified business partner maintenance,

repair and overhaul organizations.

Aircraft heavy maintenance checks consist of a series of more complex tasks that take from one to four

weeks to accomplish. The typical frequency for these events is once every 15 months. We send our aircraft to

Aeroman facilities in El Salvador, Pemco in Tampa, Florida and Embraer Aircraft Maintenance Services in

Nashville, Tennessee. In all cases this work is performed with oversight by JetBlue personnel.

Component and power plant maintenance, repairs and overhauls on equipment such as engines, auxiliary

power units, landing gears, pumps and avionic computers are performed by a number of different

FAA-approved repair stations. For example, maintenance of our V2500 series engines on our Airbus A320

aircraft is performed under a 15-year service agreement with MTU Maintenance Hannover GmbH in Germany.

Most of our maintenance service agreements are based on a fixed cost per flying hour.

Aircraft Fuel

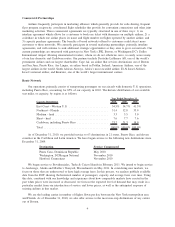

In 2010, continuing a trend that began in 2005, fuel costs were our largest operating expense. Fuel prices

and availability are subject to wide price fluctuations based on geopolitical factors and supply and demand

that we can neither control nor accurately predict. We use a third party fuel management service to procure

most of our fuel. Our historical fuel consumption and costs were as follows for the years ended December 31:

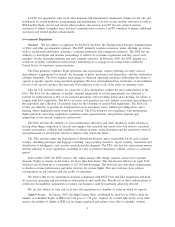

2010 2009 2008

Gallons consumed (millions) .................... 486 455 453

Total cost (millions) .......................... $1,115 $ 945 $1,397

Average price per gallon ....................... $ 2.29 $2.08 $ 3.08

Percent of operating expenses ................... 32.4% 31.4% 42.6%

Total cost and average price per gallon each include related fuel taxes as well as effective fuel hedging

gains and losses.

Our goal with fuel hedging is to provide protection against increases in fuel prices by entering into a

variety of crude and heating oil call options and collar contracts, as well as jet fuel swap agreements. At

December 31, 2010, we had hedged approximately 28% of our projected 2011 fuel requirements and 6% of

our projected 2012 fuel requirements. In January, 2011, we hedged approximately an additional 4% of our

expected 2011 fuel requirements using crude oil collars. We had no collateral posted related to margin calls on

our outstanding fuel hedge contracts as of December 31, 2010.

LiveTV, LLC

LiveTV, LLC, a wholly-owned subsidiary of JetBlue, provides in-flight entertainment, voice

communication and data connectivity services for commercial and general aviation aircraft. LiveTV’s assets

include certain tangible equipment and interests in systems installed on its customers’ aircraft, system

components and spare parts in inventory, an air-to-ground spectrum license granted by the Federal

Communications Commission, a network of approximately 100 ground stations across the continental U.S.,

and rights to certain patents and intellectual property. LiveTV’s major competitors in the in-flight

entertainment systems market include Rockwell Collins, Thales Avionics and Panasonic Avionics. Only

Panasonic is currently providing in-seat live television. In the voice and data communication services market,

LiveTV’s primary competitors are Aircell, Row 44, Panasonic, OnAir and Aeromobile.

8