Loreal 2011 Annual Report Download - page 22

Download and view the complete annual report

Please find page 22 of the 2011 Loreal annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

20 REGISTRATION DOCUMENT − L’ORÉAL 2011

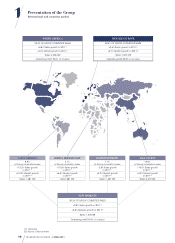

1Presentation oftheGroup

Risk factors

have implemented appropriate risk management measures.

L’Oréal plays an active role in this process for the substances

manufactured or imported by its European legal entities

concerned. Within the framework of national and European

associations, L’Oréal contributes to the analysis and drafting of

practical guides for implementation of these regulations.

L’Oréal is also subject in Europe to the 7thamendment to the

European Cosmetics Directive on animal testing of cosmetic

ingredients. An action plan has been drawn up at L’Oréalin order

to change the conception and the methods of evaluation of

the safety of raw materials. This plan is subject to an accelerated

implementation in order to prepare in the best way for the

application of these regulations which is scheduled for 2013.

1.8.2.4. Other legal risks and litigation

In the ordinary course of its business, the Group is involved in

legal actions and is subject to tax assessments, customs controls

and administrative audits. It is also the subject of proceedings

initiated by national competition authorities, in particular in

European countries (see note22.

Provisions for liabilities and

charges

on page129 in chapter4 ) .

In order to better prevent this risk, the Group’s Legal Department

has introduced a training session on competition law for the

employees concerned. In2011, it also distributed an ethical

and legal guide on the conditions of fair competition, called

“The way we compete”.

A provision is set aside in the parent company and consolidated

financial statements whenever the Group has an obligation

towards another party and will have to face a probable outflow

of economic resources whose cost can be estimated with

reliability.

We consider that there is currently no exceptional event nor

any governmental procedure, legal or arbitration proceeding

which has recently materially affected, or is seriously likely to

materially affect, the financial situation, assets or operations of

the Company and the L’Oréal Group.

1.8.3. Industrial and

environmental risks

In order to improve the efficiency and productivity of its

industrial processes, L’Oréal carries out most of its production

in 41factories, each specialising in a specific type of technology.

1.8.3.1. Production and Supply Chain

Products must be made available on the market on the

scheduled dates to meet launch deadlines and customer

demand, in order to enable new product ranges to be listed

by distribution in a cosmetics market that requires companies

to be more and more responsive.

Therefore, a major stoppage of activity in a factory or a

distribution centre could have an adverse effect on the

achievement of commercial objectives.

In order to prevent this risk, business continuity plans exist for

each operational site. They aim at anticipating the unavailability

of part of the Group supply chain as far as possible and at

restarting activities as quickly as possible.

1.8.3.2. Supplier dependence

L’Oréal is dependent on its external suppliers for the delivery

of materials (raw materials and packaging items) that are

essential for the manufacture of finished products, which

may therefore suffer disruption as the result of a default by an

important supplier.

In order to prevent these risks, L’Oréal has prepared business

continuity plans for production which aim notably at looking

for replacement solutions (for example: supplier back-up,

availability of several moulds for strategic products).

1.8.3.3. Environment, Health and Safety (EHS)

The cosmetics industry has a limited environmental risk profile.

However, as is the case for any production, distribution, research

and general administration operation, L’Oréal is exposed

to safety and environmental issues (relating, for example

to the use of certain raw materials, the use of machines or

electrical equipment in production or storage areas, handling

operations liable to cause accidents involving bodily injury,

waste water treatment etc.). The main risk faced in the Group’s

industrial sites is fire due to the inflammable materials used

in products (alcohol, propellant gases, powders, oxidants

and solvents) and the storage of combustible products and

chemicals.

1.8.3.4. EHS risk map and audits

Within the scope of this EHS policy, for the industrial sites,

the SHAP (Safety Hazard Assessment Procedure) is a hazard

prevention programme based on the assessment of risks by

employees at grassroots level under the responsibility of the

Site Manager. This programme contributes to identifying the

dangers overall and for each workstation and assessing the

corresponding risks. The SHAP method thus makes it possible

to prepare a risk mapping for the sites, to evaluate the level

of risks and to put in place the necessary means of control.

It is supported by dialogue between persons in charge,

thus contributing to a significant collective improvement in

risk management. This approach is constantly evolving and

is updated regularly depending on changes at sites and

experience on the ground. EHS audits are conducted every

three or four years in each factory and distribution centre.

The site risk map is reviewed within the scope of this audit.

In2011, an EHS risk audit was carried out at 9factories and

22distribution centres.