Loreal 2011 Annual Report Download - page 16

Download and view the complete annual report

Please find page 16 of the 2011 Loreal annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

14 REGISTRATION DOCUMENT − L’ORÉAL 2011

1Presentation oftheGroup

Operations

1.6. Operations

1.6.1. From sourcing to delivery,

continuous improvement

of industrial efficiency

The Operations Division is responsible for coordination of

production, its optimisation and distribution of products.

It comprises seven industrial and supply chain expertise :

procurement, packaging, production, quality, supply chain,

environment health and safety, and real estate. Three support

functions complete the Division’s resources: Information Systems,

Finance and Human Resources.

After integrating D istribution in2007, the Production and

Technology Division became the Operations Division.

1.6.2. A well-oiled industrial

model

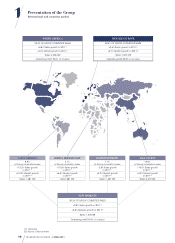

With locations all over the world, the Group’s plants produce 87%

of cosmetics units sold. This choice of in-house production offers

a guarantee of quality and traceability and reduces risks. Plants

are generally dedicated to the production of one Operational

Division and a limited number of product categories. The rotation

of brands on the packaging lines is furthermore assisted by an

increased standardisation of industrial processes.

This industrial model avoids the need to multiply the number of

sites, helps to improve efficiency and guarantees continuous

activity on each site.

1.6.3. Continuous improvement

and optimisation

ofproduction

L’Oréal has set itself the target of continually improving output

and optimising production costs. This ambition is accompanied

by a demanding quality system. It guarantees the integrity of

the formulation of products all over the world and ensures

compliance with social and environmental responsibility

standards on each production site in accordance with national

regulation.

In2008, L’Oréal launched a global programme to improve

the efficiency of its production facilities. Based on a set of best

practices, this programme is shared by all sites. This triggered

mutualisation of the support and procurement functions in the

five major geographic zones. Efficiency has been improved

while the specificities of each region have been maintained. This

productive, highly responsive organisation model is particularly

adapted to L’Oréal’s objective of accelerated growth in the

New Markets.

1.6.4. Long-term partnerships

with suppliers

L’Oréal’s industrial success can also be accounted for by the

Group’s exacting standards in the choice of its suppliers and

the sustainable relationships that it sets up with them. In2010,

the Group initiated the “wall-to-wall” programme which consists

in setting up a production unit for packaging items operated

by a supplier within the plant itself. This partnership develops

responsiveness and industrial flexibility, while reducing the

transportation of packaging items and the generation of waste

related to their packaging. It is aimed at plants with highly

specialised technologies that produce very large volumes and

have ongoing needs for external resources.

1.6.5. L’Oréal and its partners:

working together to

innovate

Packaging is a major environmental and industrial challenge

for the Operations Division. The Group responded to this

challenge in2010 by creating a packaging fair called “Cherry

Pack”. International suppliers are able to propose their latest

innovations at this event on an exclusive basis. At the end

of the two days of presentation, projects are selected by the

brands and the Research & Innovation Division. This event

shows L’Oréal’s intention to reinforce its links with its suppliers

by counting on collaborative intelligence.

1.6.6. Strong commitments

with regard to social

responsibility and safety

The Operations Division, like the Group as a whole, plays a

predominant role in the field of social responsibility and safety.

Through its “Buy & Care” programme, L’Oréal incites its suppliers

to be more responsible and carries out rigorous monitoring of

their commitments through a large number of social audits on

suppliers throughout the world. The objective is not to sanction

suppliers' premices but to help them to improve their safety

standards and their environmental and social performances.

In creating the “Solidarity Sourcing” programme, the Group took

the initiative of using local suppliers who make commitments in

favour of minorities: disabled workers or workers from deprived

communities. It may also involve very small suppliers or fair trade

players that L’Oréal valorises with the help of its suppliers.