Nissan 2008 Annual Report Download - page 25

Download and view the complete annual report

Please find page 25 of the 2008 Nissan annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

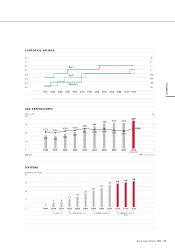

NISSAN EXCELLENCE PROGRAM (NEP) TEAMS QUALITY EXPERT

REINFORCEMENT FOR DESIGN

REVIEW PROMOTION

Quality

Leader-

ship

Top level in

more influential

Index

Top level of

customer

experience

Top level of

attractiveness

Design Quality Improvement

Production Quality Improvement

Break-down Quality Improvement

Countermeasure Speed Improvement

Supplier Quality

CS improvement for sales activity

CS improvement for service activity

Product Competitiveness

Perceived Quality

250 4,300persons

Crew

Design review staff

51,000persons

Pilot

Quality coaching

250persons

Expert

Complex issue solution

23

Nissan Annual Report 2008

NISSAN GT 2012

KAZUMASA KATOH

Senior Vice President

investigate and analyze the problems using the latest

technology and available data. After the FQCs were

established, the number of parts collected for this

purpose nearly quadrupled, providing an even more

reliable statistical base.

The process of delving into quality issues is known

as Field Quality Investigation and Analysis, or FQIA.

FQIA involves collecting both problem parts and non-

defective ones in large quantities, analyzing them, and

then duplicating the operating conditions under which

the problem occurred. These highly reliable methods

have allowed us to pinpoint the root cause and take

the necessary measures for improvement. The overall

objective here is to make improvements so quickly that

we exceed our customers’ expectations.

Representatives of our suppliers stationed at our

FQCs work alongside staff from various functions

within Nissan—including development, production,

market quality improvement, and quality assurance—

to investigate the problems and take appropriate and

immediate countermeasures. By studying actual

problem parts gathered in the field together, they are

able to come up with the optimal solution in the

shortest period of time. One specific goal we have is

to cut the time needed to process claims by half.

Car buyers place a great deal of emphasis on

how their peers perceive the quality and

attractiveness of a particular vehicle. This will involve

revamping and upgrading our product planning

process. Our target for enhancing perceived quality

and attractiveness is to have more than half of our

new models earning top ratings from customers.

To achieve a top customer satisfaction rating in

sales and service quality in Japan, the U.S., Europe

and four main GOM regions, we are establishing a

global sales and service quality department. To

ensure superior customer service, we are introducing

the Nissan Sales and Service Way into 7,000

dealerships and providing 130,000 staff with high-

quality training around the world.

In addition, we set up the Nissan Customer

Service Center (NCSC) to enhance the total

customer experience. Our support hotline, after-sales

support at sales companies, and technical support

service were once separate in Japan. Now they all

operate under the NCSC umbrella, and share

information from customers as well as product failure

analysis data. Aided by the digitalization of product

information and the introduction of a new call-

handling process, the customer support hotline

provides better response to inquiries and reduces

waiting time for customers. Certain roles and

specified after-sales support functions from each of

the seven Area Technical Centers are also now

consolidated under the NCSC. This consolidation has

quickened our after-sales team’s response time.

Our goal for upgrading management quality is to

bring the results of the annual employee survey up to

the highest levels in the industry.

Over the course of NISSAN GT 2012, we hope to

further deepen the loyalty of our employees as we

become a leader in the realm of quality, win the trust

of consumers, and transform ourselves into a company

with the proven ability to grow in a sustainable manner.