Konica Minolta 2010 Annual Report Download - page 19

Download and view the complete annual report

Please find page 19 of the 2010 Konica Minolta annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

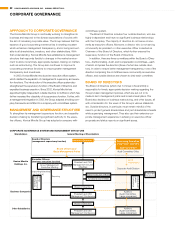

ACCELERATE DEVELOPMENT OF NEW BUSINESSES

LEDs have become the focus of attention as next-generation lighting

sources. As demand for higher light output and longer life for individual

LED modules grows, measures to combat the heat these modules gener-

ate will be critical. Glass materials are resistant to deterioration from heat,

and Konica Minolta has advantages in glass and plastic mold technologies.

We will leverage these capabilities to offer seals, lenses and other compo-

nents for LED modules.

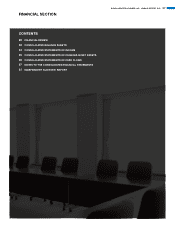

The scope of use for inkjet printers extends far beyond printing to include

potential applications in manufacturing and an extremely diverse range of

other applied fields. Konica Minolta has proprietary technology in piezo-

electric DOD (drop on demand) techniques, and also sells products such

as high-performance printer heads compatible with a variety of media

(paper, film, fabric, metal and other basic materials), multi-functional ink,

and textile printers. With the adoption of inkjet technology gaining ground

most notably in the commercial printing field, Konica Minolta will extend its

business scope to include the field of industrial printing.

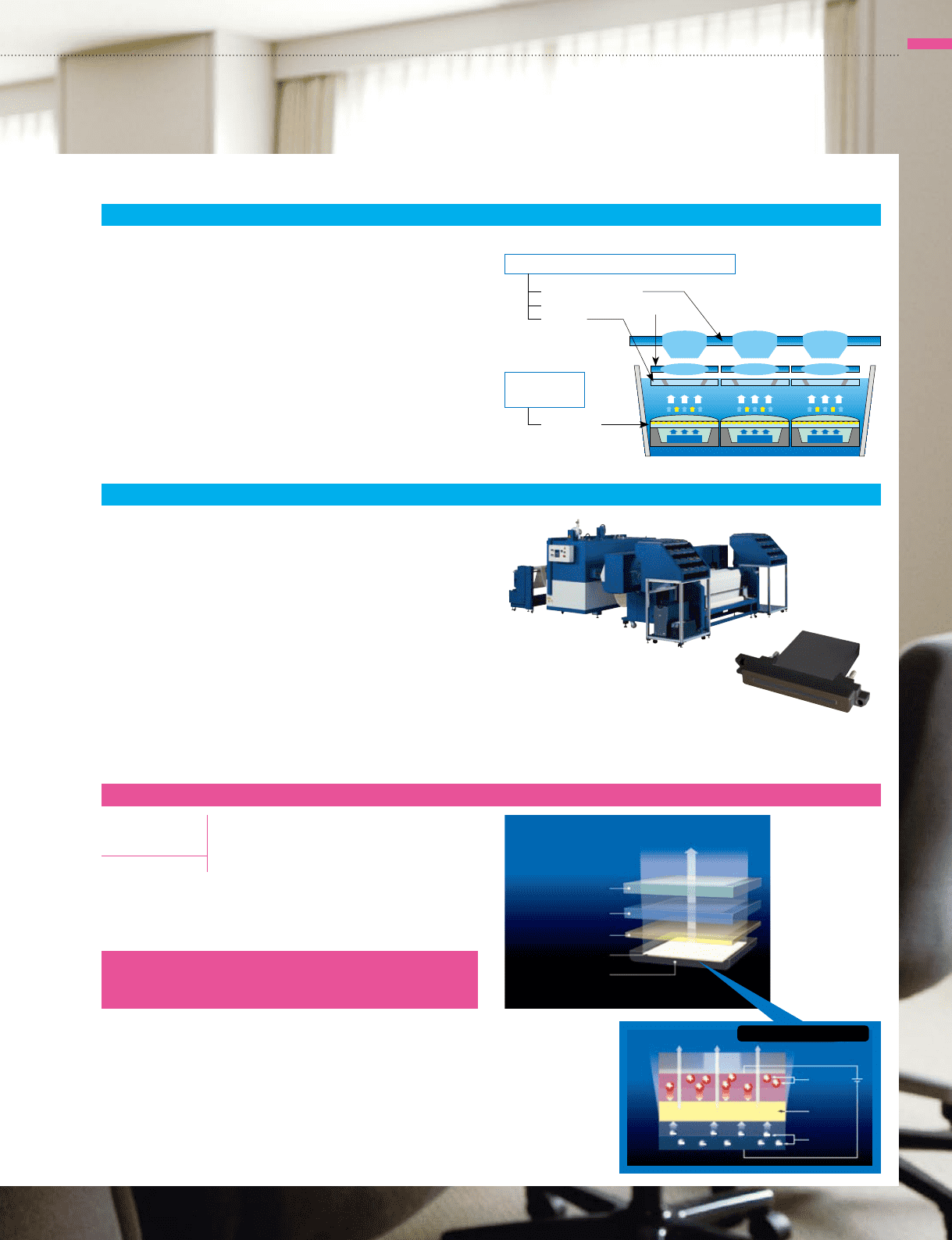

Leveraging the superior qualities of thin, lightweight, flexible film light

sources, Konica Minolta will establish a base in the environment and

energy field as a new business.

ENTRY INTO THE LED LIGHTING MATERIALS AND COMPONENTS BUSINESS

EXTEND BUSINESS SCOPE IN THE INKJET SECTOR

OLED LIGHTING BUSINESS

n Material synthesis technology

(blue phosphorous materials)

n Thin-film coating technology

(roll-to-roll method)

SUPERIOR

KONICA MINOLTA

TECHNOLOGIES

“KM1024 Series” inkjet head

Distinct Features of OLED

•Minimalenvironmentalimpact

•Thinandflexible

•Emitslightfromasurface

•Generateslittleheat

White light

Blue LED

Structure of LED Lighting

Glass/Plastic Mold Technologies

Light distribution lens

Divergent/convergent lens

Reflector

LED cover

Glass Mold

Technology

“Nassenger V” inkjet textile printer

Structural Diagram of OLED Light Sources

Out-couplingfilm

Substratefilm

Barrierlayer

Organicemissivelayer

Encapsulationfilm

Lightemission

Hole

Lumines-

cencelayer

Electron

Lightemission

Organicemissivelayerclose-up

Anode

Cathode

Anode

KONICA MINOLTA HOLDINGS, INC. ANNUAL REPORT 2010 17