Audi 2008 Annual Report Download - page 27

Download and view the complete annual report

Please find page 27 of the 2008 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

here under Timm’s direction. Team

members from all disciplines are mak-

ing important contributions to tech-

nological progress; their thinking and

experimentation extend across de-

partmental boundaries. Experts

developing new technologies and

processes work in direct contact with

the project managers developing new

vehicles. With everything taking place

under the same roof, the lines of com-

munication are shortened.

At first, the idea of using lightweight

aluminum – which weighs about a

third less than steel – on a large scale

in automobile production was met by

most experts with skepticism. But

Timm worked persistently to over-

come all objections. For a creative

thinker like him, one thing was clear

from the start: Simply duplicating the

existing steel structure in aluminum

would not be a recipe for success –

after all, such a new construction

would be substantially more expen-

sive. So other advantages had to be

weighed – for instance, finding new

ways to reduce the number of parts

required. “The bottom line is that

30 percent fewer parts means 30 per-

cent less logistics and 30 percent

fewer joins. So we immediately took

another look at our production

processes and sought new ways to

optimize our design geometry by se-

lecting the most suitable materials,”

recalls Timm. AUDI AG has already

received numerous awards for this

pioneering achievement; most re-

cently by winning the 2008 European

Inventor of the Year Award for its

Space Frame technology.

Today’s challenges resemble the

Olympic motto “faster, higher, fur-

ther.” Translated into the language of

materials experts, this means: sta-

bler, stronger, lighter. New aluminum

alloys, for instance, are intrinsically

stronger and can withstand greater

mechanical loads. Conversely, engi-

neers are able to design metallic com-

ponents that are thinner throughout,

thereby reducing weight further. “We

don’t just focus on the basic material:

We also find ways to manufacture it

industrially and therefore more eco-

nomically,” emphasizes Dr. Lutz-Eike

Elend, Head of Lightweight Design

Technology and Process Development.

Aluminum has long since ceased to

be the only interesting material for

building auto bodies. Audi specialists

are working with plastics, magnesium

alloys and steel alloys. The latest

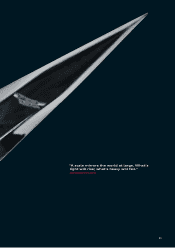

trend in airframe design is using car-

bon fiber composite (CFC) materials,

in which carbon fibers of different

lengths and orientations are em-

bedded in a mush of plastic and then

baked in an oven. 20 percent of the

A380 Super-Airbus is made out of CFC

and up to 50 percent of the latest

Boeing 787 is made of this material.

Automakers don’t intend to take a

back seat in this area: One option on

the Audi R8 supercar is to have the

sideblades made from this high-tech

material. This and other bold ideas

from Technical Development experts

are creating new challenges for

Michael Ernst, Head of the Technical

Center, and his team, whose job it is

to implement them at the Aluminum

and Lightweight Design Center.

Tricky problems invariably arise when

different materials have to be meshed

together. “We make every effort to

combine even ‘incompatible’ mate-

rials,” says Ernst. “Basically, anything

is doable. But in order to ultimately

shorten the cycle times, our lab re-

sults have to translate it into actual

automobile production.”

“We make every effort to combine even

‘incompatible’ materials.”

Michael Ernst, Head of the Technical Center of the Aluminum and

Lightweight Design Center, AUDI AG

Pioneering spirit Vorsprung

23