North Face 2015 Annual Report Download - page 22

Download and view the complete annual report

Please find page 22 of the 2015 North Face annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.VF’s centralized global supply chain organization is responsible for producing, procuring and delivering

products to our customers. VF is highly skilled in managing the complexities associated with our global supply

chain. On an annual basis, VF sources or produces approximately 557 million units spread across more than 30

brands. Our products are obtained from 28 VF-operated manufacturing facilities and approximately 1,900

contractor manufacturing facilities in over 60 countries. Additionally, we operate 32 distribution centers and

1,520 retail stores. Managing this complexity is made possible by the use of a network of information systems for

product development, forecasting, order management and warehouse management, along with our core enterprise

resource management platforms.

In 2015, 23% of our units were manufactured in VF-owned facilities and 77% were obtained from

independent contractors. Products manufactured in VF facilities generally have a lower cost and shorter lead

times than products procured from independent contractors. Products obtained from contractors in the Western

Hemisphere generally have a higher cost than products obtained from contractors in Asia. However, contracting

in the Western Hemisphere gives us greater flexibility, shorter lead times and allows for lower inventory levels.

This combination of VF-owned and contracted production, along with different geographic regions and cost

structures, provides a well-balanced, flexible approach to product sourcing. We will continue to manage our

supply chain from a global perspective and adjust as needed to changes in the global production environment.

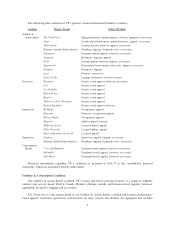

VF operates manufacturing facilities in the U.S., Mexico, Central and South America, the Caribbean and

Europe. A significant percentage of denim bottoms and occupational apparel is manufactured in these plants, as

well as a smaller percentage of footwear. For these owned production facilities, we purchase raw materials from

numerous U.S. and international suppliers to meet our production needs. Raw materials include products made

from cotton, leather, rubber, wool, synthetics and blends of cotton and synthetic yarn, as well as thread and trim

(product identification, buttons, zippers, snaps, eyelets and laces). In some instances, we contract the sewing of

VF-owned raw materials into finished product with independent contractors. Manufacturing in the U.S. includes

all Major League Baseball uniforms, along with screen printing and embroidery of jerseys, T-shirts and fleece

products. Fixed price commitments for fabric and certain supplies are generally set on a quarterly basis for the

next quarter’s purchases. No single supplier represents more than 10% of our total cost of goods sold.

Independent contractors generally own the raw materials and ship finished ready-for-sale products to VF.

These contractors are engaged through VF sourcing hubs in Hong Kong (with satellite offices across Asia) and

Panama. These hubs are responsible for coordinating the manufacturing and procurement of product, supplier

management, product quality assurance, and transportation and shipping functions in the Eastern and Western

Hemispheres, respectively. Substantially all products in the Outdoor & Action Sports and Sportswear coalitions,

as well as a portion of products for our Jeanswear and Imagewear coalitions, are obtained through these sourcing

hubs. For most products in our Contemporary Brands coalition, we contract the sewing and finishing of VF-

owned raw materials through a network of independent contractors based primarily in the U.S.

Management continually monitors political risks and developments related to duties, tariffs and quotas. We

limit VF’s sourcing exposure through, among other measures: (i) diversifying geographies with a mix of VF-

operated and contracted production, (ii) shifting of production among countries and contractors, (iii) sourcing

production to merchandise categories where product is readily available and (iv) sourcing from countries with

tariff preference and free trade agreements. VF does not directly or indirectly source products from suppliers in

countries that are prohibited by the U.S. State Department.

All VF-operated production facilities throughout the world, as well as all independent contractor facilities

that manufacture VF products, must comply with VF’s Global Compliance Principles. These principles,

established in 1997 and consistent with international labor standards, are a set of strict standards covering legal

and ethical business practices, workers’ ages, work hours, health and safety conditions, environmental standards

8