Pentax 2007 Annual Report Download - page 12

Download and view the complete annual report

Please find page 12 of the 2007 Pentax annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

10

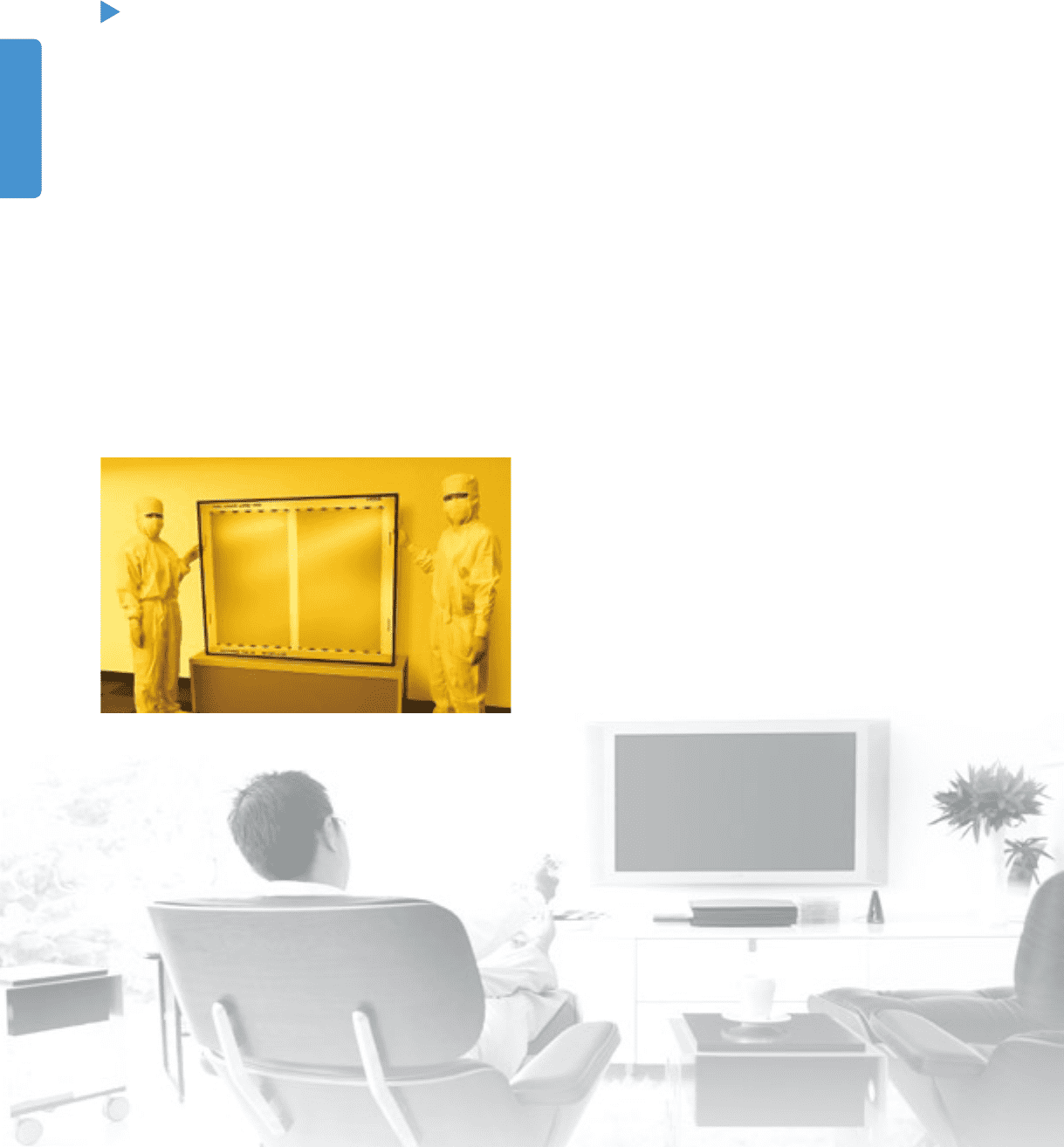

Large-sized LCD photomask (1,220mm x 1,400 mm) used for eighth-generation LCD panels.

Electro-Optics Division

LCD Photomasks

Electro-Optics Division

Hoya’s photomasks are at work behind the scenes,

helping to bring the world larger, higher definition LCD televisions

LCD photomasks are the master plates that are used in the

manufacture of the LCD panels found in large flat televisions and

computer monitors. Hoya is the world’s leading producer of LCD

photomasks, and it has special strengths in the production of

large-scale LCD photomasks.

The major factor in today’s demand for LCDs is the constant

increase in the size of LCD televisions. There is a corresponding

demand for ever larger LCD photomasks. LCD panels are

classified according to their size as fifth-generation,

sixth-generation and so on*1, depending on the size of the

“mother glass” panels used in their mass production. During

2006, LCD panel manufacturers were active in the production of

sixth- and seventh-generation panels, responding to the demand

for larger LCD panels and aiming for greater production efficiency.

There was also a move by some manufacturers to the production

of eighth-generation panels.

In response to the large-scale increase in production by panel

manufacturers, photomask producers also boosted their

production capacity. As a result, declining prices due to growing

competition between manufacturers were clearly witnessed in the

photomask market. Despite this environment, Hoya, by

introducing further improvements to photomask quality, helped

LCD panel manufacturers not only to improve the quality of their

products but also to lower their production costs. Of special note

is the multi-tone mask*2 that Hoya has been able to bring to

fruition through the application of its advanced engineering

strengths. These masks make it possible for panel manufacturers

to reduce costs by realizing around a 20% reduction in the number

of production processes. As another way of differentiating its

products in the market, Hoya is contemplating applying the

technologies it has developed for its higher-precision

semiconductor photomasks in the quality assessment of its

LCD masks.

In the fiscal year ended March 31, 2007, the respective

functions of the Kumamoto (Japan), Taiwan and South Korea

plants were delineated, and Hoya worked to solidify a tripolar

production system. Each plant is located in close proximity to its

client LCD panel manufacturers, enabling Hoya to develop

products that meet the needs of each respective market, and to

shorten delivery times. Hoya is also working to realize further

efficiencies in production processes. These strategies position

Hoya to continue to enhance its competitiveness. Also during the

year, Hoya’s plant in Malaysia commenced production of the mask

blanks that are the substrates for photomasks. Hoya believes that

the application of an integrated manufacturing process—from

mask blanks to photomasks—will add further value to

Hoya’s products.

LCD Photomasks

*1. Panel manufacturers’ mother glass plate sizes:

Fifth-generation: 1,100 mm x 1,300 mm (yielding three 32-inch wide LCD television panels).

Sixth-generation: 1,500 mm x 1,850 mm (yielding eight 32-inch wide LCD television panels).

Seventh-generation: 1,870 mm x 2,200 mm (yielding three 50-inch wide LCD television panels).

Eighth-generation: 2,160 mm x 2,400 mm (yielding six 50-inch wide LCD television panels).

*2. A photomask that allows for mid-range light penetration through pattern shrinkage and semitransparent film.